- Posts: 2

- Thank you received: 0

Login Form

Solid Models!

12 years 4 months ago - 12 years 4 months ago #1247

by molitor

Solid Models! was created by molitor

Hi all. I'm Clint, I am new, and I have plenty of drafting and design experience. So, on to business. I have downloaded what files i could that accompanied the Quickie Q200 Kits when they cam out. Thankfully, lots of people have realized that the web is a great way to exchange files and that old prints can be scanned and made into digital files. I have collected a few of the digital mediums and have started converting them into solid models. I would be happy to do so for anybody who would like to have their napkins, paper sacks, or beer boxes translated into actual drawings that are universally interchangeable with most CAD software.

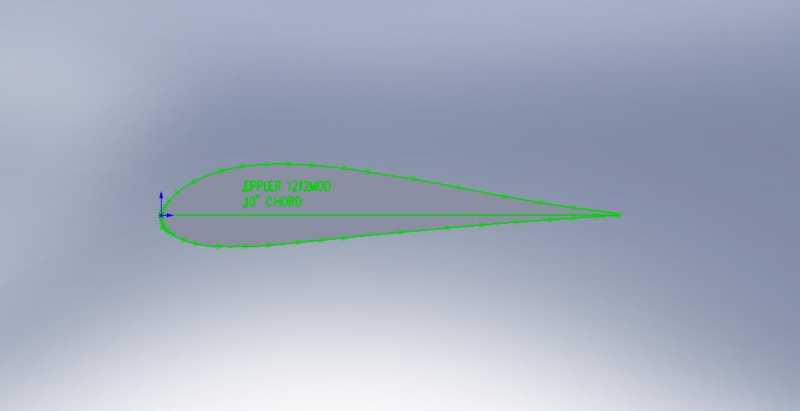

SKETCH VIEW

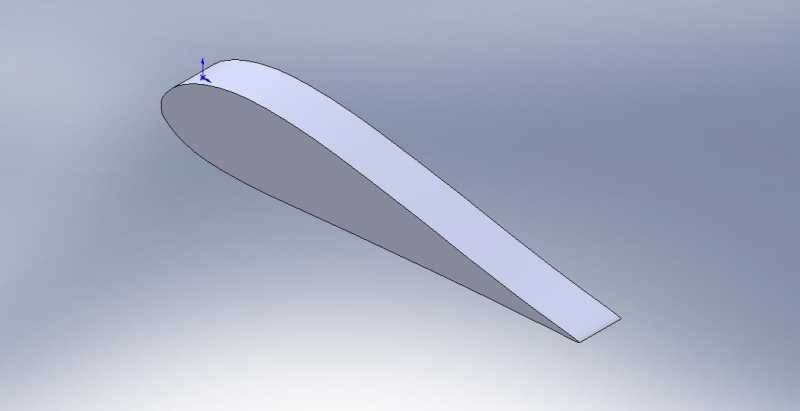

ISOMETRIC VIEW

SKETCH VIEW

ISOMETRIC VIEW

Last edit: 12 years 4 months ago by molitor.

Please Log in or Create an account to join the conversation.

12 years 4 months ago #1248

by admin

Flying an aeroplane with only a single propeller to keep you in the air. Can you imagine that?

— Captain Picard, from 'Star Trek: The Next Generation' episode 'Booby Trap.'

Replied by admin on topic Re: Solid Models!

Hey Molitor,

Not sure exactly what service you are offering here. Please be more specific.

DXF drawings of the Q2 and Quickie templates are available in the online store here on the site. I also have solidworks renderings of all of the metal parts for the Q2/Q-200.

No need to re-invent the wheel here, but it would be nice to collaborate with someone who has some drafting skills!

Let me know what you had in mind.

Thanks,

Dan Yager

QBA Editor

www.quickheads.com

Not sure exactly what service you are offering here. Please be more specific.

DXF drawings of the Q2 and Quickie templates are available in the online store here on the site. I also have solidworks renderings of all of the metal parts for the Q2/Q-200.

No need to re-invent the wheel here, but it would be nice to collaborate with someone who has some drafting skills!

Let me know what you had in mind.

Thanks,

Dan Yager

QBA Editor

www.quickheads.com

Flying an aeroplane with only a single propeller to keep you in the air. Can you imagine that?

— Captain Picard, from 'Star Trek: The Next Generation' episode 'Booby Trap.'

Please Log in or Create an account to join the conversation.

12 years 4 months ago - 12 years 4 months ago #1250

by molitor

Replied by molitor on topic Re: Solid Models!

I'm offering to convert personal modifications to models that people can use. I'm sure alot of people have parts that they have modified themselves to overcome problems they have encountered with their individual aircraft.

For Example: An individual may have decided to modify a linkage that was originally installed in their kit in a position that they personally find to be cumbersome. They might tear into their bulkhead or wall to move a bracket to a better location, This can easily be remedied by and offset mounting bracket or a change of orientation. While this easy to do with a sheet metal bracket, the bracket might not be as substantial as the innovator had envisioned. With the 3d model of this part, changes can be easily made and the updated model can be delivered to a Machine Shop to be Milled from a solid piece of stock or precision molded or bent.

I really didn't have an aim with my directiveother than to offer help where I could. I work for a company that Designs and Builds Technology for a variety of industries and 3D models that are infinitely configurable are a valuable asset.

My company's website is www.pcdworks.com if you would like to peruse the documentation on there it may be of interest.

For Example: An individual may have decided to modify a linkage that was originally installed in their kit in a position that they personally find to be cumbersome. They might tear into their bulkhead or wall to move a bracket to a better location, This can easily be remedied by and offset mounting bracket or a change of orientation. While this easy to do with a sheet metal bracket, the bracket might not be as substantial as the innovator had envisioned. With the 3d model of this part, changes can be easily made and the updated model can be delivered to a Machine Shop to be Milled from a solid piece of stock or precision molded or bent.

I really didn't have an aim with my directiveother than to offer help where I could. I work for a company that Designs and Builds Technology for a variety of industries and 3D models that are infinitely configurable are a valuable asset.

My company's website is www.pcdworks.com if you would like to peruse the documentation on there it may be of interest.

Last edit: 12 years 4 months ago by molitor.

Please Log in or Create an account to join the conversation.

8 years 5 months ago #1518

by NateD2

Replied by NateD2 on topic Re: Solid Models!

Dan, what solidworks renderings of the metal parts are we talking about? The Fuselage model I have + the wing files you talk of + the metal parts sounds like a nearly complete kit 3D model.

Just curious....

Just curious....

Please Log in or Create an account to join the conversation.

- AlanThomas

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 0

8 years 4 months ago #1529

by AlanThomas

Replied by AlanThomas on topic Re: Solid Models!

I use AutoCAD inventor which should be able to import your files. If it is possible what I would love to do is convert these files to a file suitable for my 3-D printers. My biggest 3-D printer is 500 x 500 x 300. Following up with the making of various parts what I have been doing is producing a drawing of the relevant part, making a 3-D print of that part out of PLA and then using the lost wax style of process making aluminium parts. For example the biggest item I have made is an intake manifold for a very large V8 racing car. Of course I make all manner of small parts. Should be fun.

Please Log in or Create an account to join the conversation.

Moderators: JonMatcho

Time to create page: 0.907 seconds

©2024 www.quickheads.com