Q1 Plans Chapter 14 Page 14-6

- Details

- Category: Quickie Plans

- Published: Monday, 12 May 2008 10:28

- Written by Dan Yager

- Hits: 2120

FRONT COCKPIT COVER

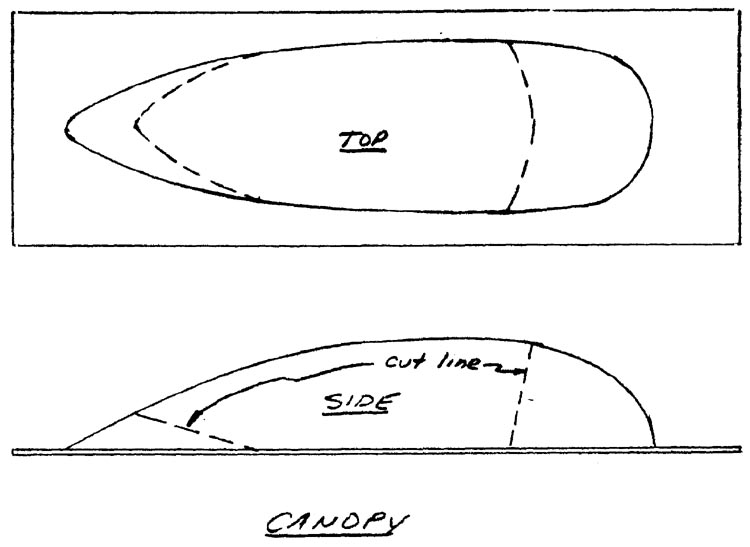

The first step toward installing the canopy is to make the front cockpit cover. This cover is heat formed similarly to what you did on the fuel tank and seat-back bulkhead.

The cover extends from the forward face of the firewall to STA58(initially). Use the firewall and the instrument panel bulkhead to aid in contouring the cover.

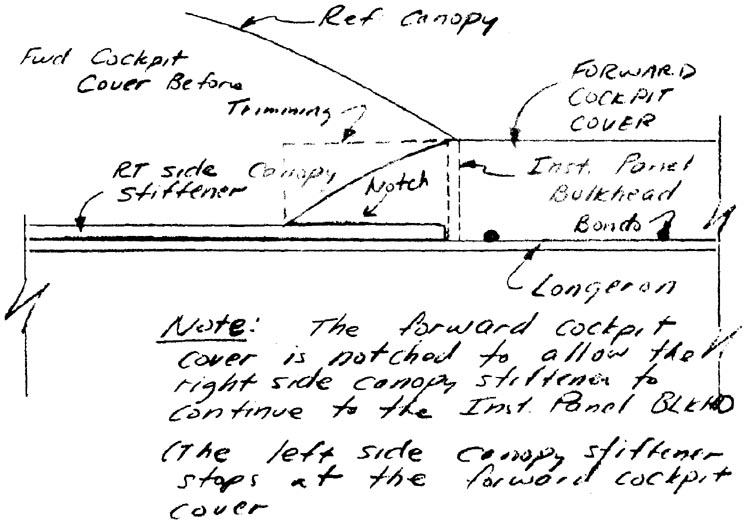

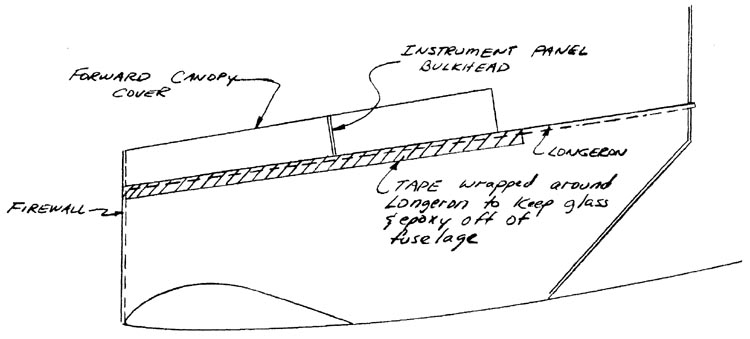

Begin by temporarily installing instrument panel bulkhead at STA37.5 with dabs of Bondo. Next, rough cut a piece of orange foam and begin heat forming it to the required shape. Go slow, and check for dips and bumps often. When you have it formed, Bondo it in place to the fuselage at the longerons. Next, layup 2 BID at 45 deg. to BL00 on the top of the cover. Using tape to wrap around the longeron and fuselage sides will facillitate keeping the epoxy off of the fuselage. Knife trim the glass even with the longerons.

After the layup has cured, remove the cover from the fuselage and layup one BID on the inside face. Let the layup become very tacky, and then put it back on the fuselage so that it will cure in the proper position. If the cloth is not tacky, the glass will fall off of the foam when it is upside down. Check the layup often.

The instrument panel bulkhead is mounted to the front cockpit cover with one BID tape front and back.

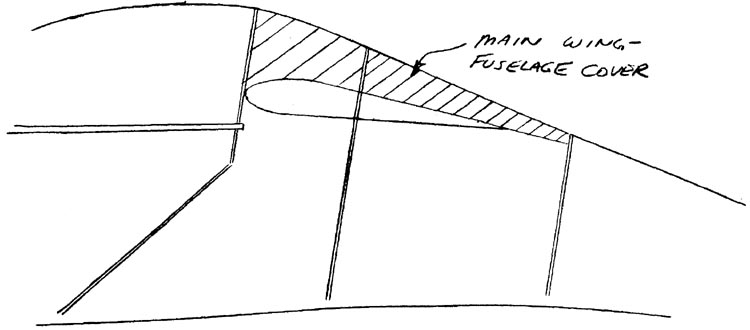

MAIN WING-FUSELAGE COVER

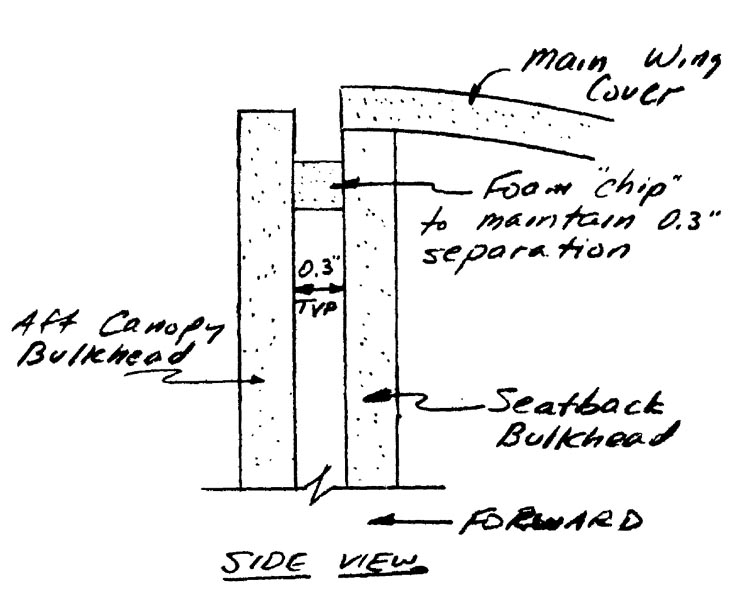

Once the main wing has been mounted to the fuselage, and the aileron control system permanently installed, and the canopy mounted, the main wing-fuselage cover can be formed and installed.

The material used is the orange foam. You will probably find it easier to make the top in two pieces: one piece from the canopy to the FS89 bulkhead, and the second piece from the FS89 bulkhead to the FS110 bulkhead.

The foam is formed using the bulkheads as well as using the contouring of the existing fuselage, in order to come up with a shape that is pleasing.

Once the shape is developed, layup one BID on the inside face of the cover. Let it become tacky, so that it won’t fall off if turned over, and then position the wing-fuselage cover on the fuselage. You may either use some Bondo to hold the cover in place, or you may go right ahead and layup one BID over the outside face using a typical 1” overlap. Use dry micro before the layup to fill the voids around the joints.

Make sure that you don’t get epoxy on the aileron system.

END OF CHAPTER