- Details

-

Category: Quickie Plans

-

Published: Monday, 12 May 2008 12:27

-

Written by Jun Su

-

Hits: 4828

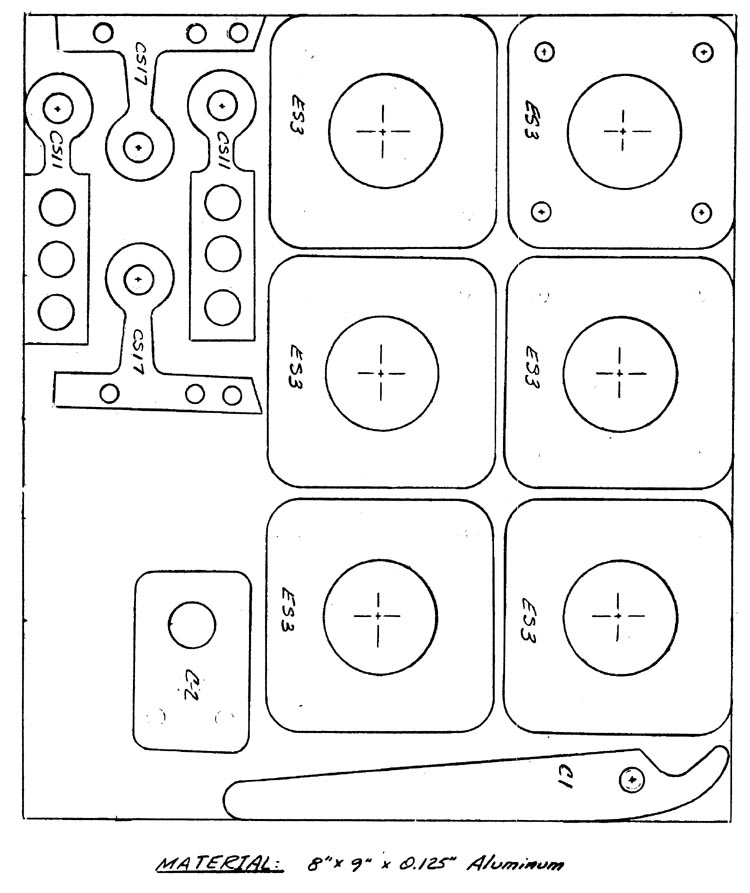

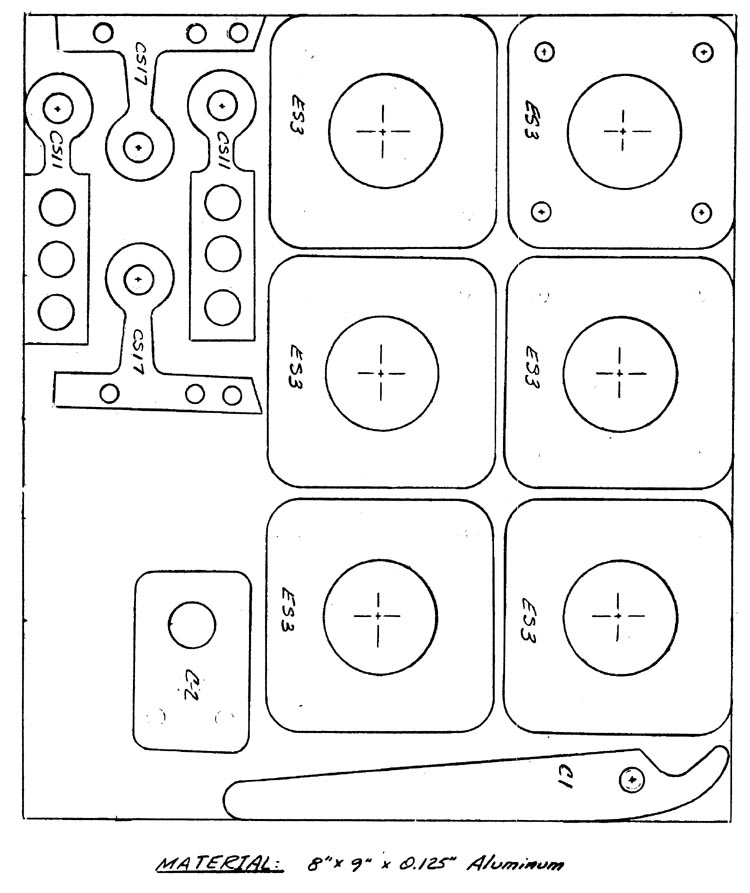

MAKING THE .125" ALUMINUM PARTS

Included in this section is a full

size layout to allow you to make all of

the .125" thick aluminum parts in the

aircraft. All parts are numbered, and

these numbers should be written on the

pieces as soon as they have been made

to avoid loosing track of them.

ES3 are the engine mount plates.

As you can see, there are three pairs

of two. The four holes on the first

layout are .189" diameter. The first

one should be used to drill the holes

in the next two, and then these three

should be labled left, right, and center,

and then used to drill in the remaining

one of each pair. Don't allow the pairs

to become intermingled. The hole in

the center of ES3 is 1.25" in diameter.

It may be cut with a hole saw or fly

cutter. As before, cut this hole in

pairs.

The holes in the eyes of CS11 (2)

and CS17 (2) are 5/16" diameter. The

rest of the holes in these pieces are

to help the bonding and need be only

the approximate diameter shown.

The hole shown in C1 is 5/16"

diameter, and a CSM4 bushing is pressed

into the hole after it is drilled. The

hole in C2 is 1/2" diameter.

The squares are used for nutplate

mounting.

CSM4 bushings should also be

pressed into the "eyes" of the two

CS17's and the two CS11's.