Q-talk 87 - Cowl Flap - Magneto Mysteries Revealed

- Details

- Category: Q-Talk Articles

- Published: Wednesday, 23 December 2009 16:24

- Written by Dave Richardson

- Hits: 3307

Magneto Mysteries Revealed

Dave Richardson, Stow, OH

This is the first article in a two or possibly three-part series on the topic of magnetos. This issue will cover the fundamental principles of a modern magneto. The next issue will be an addendum to the Teledyne Continental Motors (TCM) service manual for the D4RN-3000 magneto used in the Revmaster 2100D engine. The TCM manual is designed to provide information for both left and right hand turning engines, pressurized and non-pressurized engines and many other issues that do not relate the magneto used on the Revmaster. The addendum will isolate and cover only those issues related to that specific magneto. I would ask that someone in the QBA familiar with magnetos used in 0-200 engines prepare the final installment of this series.

Information about how to obtain TCM magneto service manuals and other background material will be included in the next edition of Q-Talk.

If you are like me, magnetos have been pretty much a "black box" that only those anointed by the FAA should be allowed to peer inside at their many wonders. Actually, there might be some things you can test and correct in an effort to get the optimal spark to be produced by your magneto.

Magneto Basics

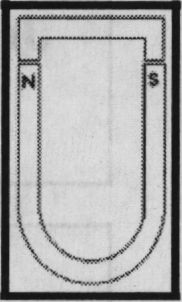

By now, everyone has seen in science class how lines form when you place a horseshoe magnet under a piece of paper sprinkled with iron filings. The iron filings collect and even stand on end along the curved "lines of flux." These flux lines can be concentrated if you replace the piece of paper and iron filings with a piece of soft iron shaped like the letter C that spans the gap between the two poles of the horseshoe magnet. The flux lines find it up to 2700 times easier to go through soft iron than air.

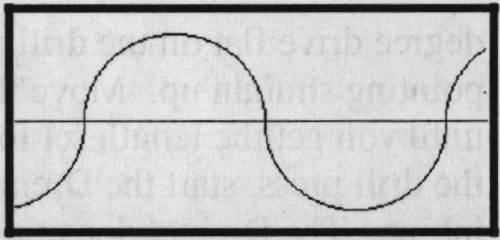

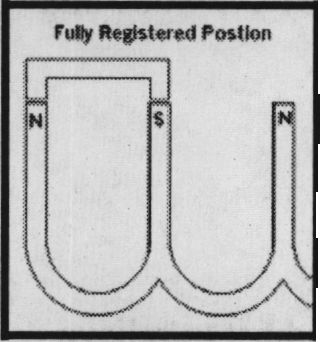

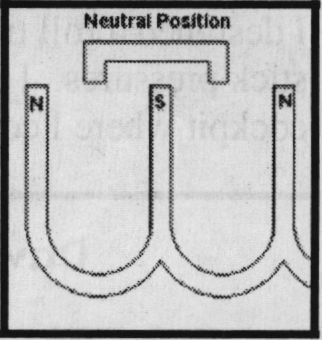

If you placed two horseshoe magnets beside each other where the two center poles are of the same orientation (e.g. both South poles) and you moved the C-shaped soft iron piece from one of the horseshoes to the other, you get an interesting effect. The lines of flux actually change from a North-South orientation to South-North in the same C-shaped piece of iron. That means that as you move the C-shaped piece of iron from one magnet to the other, the lines of flux go from completely one direction to less and less until there are no lines of flux in the C-shaped piece of iron before reversing and increasing more and more in the opposite direction until it reaches the maximum when over the second magnet. If you were to chart this change in flux, you would see a sine wave form. If you linked an infinite number of horseshoe magnets in the manner described above and pass the C-shaped piece of soft iron across the magnets, then the lines of flux will continue to alternate indefinitely.

Another interesting property of magnets occurs when you pass one through the center of a coil of wire. If you connected a voltmeter to either end of the coil and pass the magnet inside the coil, you will see both positive and negative voltages being generated depending on the direction you move the magnet. Most generators work on this principle. Also, if you pass a current from a battery through a coil of wire, the coil generates a temporary magnetic field. This is how junkyard electromagnets work.

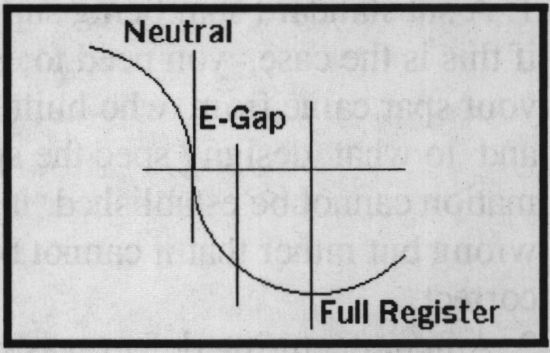

When you wrap the center of the C-shaped piece of soft iron with insulated copper wire, you can measure alternating positive and negative voltages being produced as you pass the iron piece and coil from magnet to magnet. The faster you move the C-shaped piece over the magnets. the greater the voltages produced. The voltages passing through the coil also generates a magnetic field and turns the coil and C-shaped soft iron piece into an electromagnet. As the C-shaped piece of iron with the coil is moved from horseshoe magnet to horseshoe magnet, the building electromagnetic force begins to "push" against the similar pole of the magnet that originally created the current. When the end of the C-shaped piece of iron is directly over both the North and South poles of the horseshoe magnet, the C-shaped piece is said to be in the "Fully Registered" position because the flux lines are at their maximum. When both ends of the C-shaped piece of iron are equally between the North and South poles of the magnet, this is called the "Neutral" position because there are very few, if any, lines of flux or voltages formed in the C-shaped piece of iron.

If you wrap the original coil of copper wire with 1000 times as many strands of a much thinner insulated wire, the thinner wire is "induced" to multiply the voltage of the larger wire coil also by 1000 times. With the original large coil of wire, or primary coil, and the new thinner coil of wire, called the secondary coil, wrapped around the center portion of the C-shaped piece of iron, you can pass this over the endless line of horseshoe magnets and slosh some fairly high voltages and magnetic fields back and forth inside the C-shaped piece of iron and the coils.

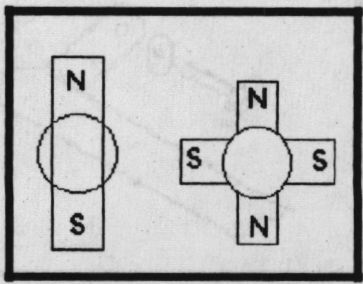

The endless line of horseshoe magnets is impractical. It can be replaced by a minimum of one bar magnet or four horseshoe magnets shaped something like a plus sign (+) when viewed from above. When spun, this can produce the effect of an endless array of magnets. Now that we have a practical set of magnets, we need a method to be able to tap into the high voltages so it can be delivered to the spark plugs. A switch is required between the two ends of the primary coil. Breaker points, actuated by a cam located on a shaft that goes through the center of the magnets, can be timed to open and close at the optimal points in the rotation of the magnets. The cam is designed to open the points after the Neutral position but before the Full Register position where the magnetic disagreement between the magnets and the forming electromagnetic coil in the C-shaped piece of iron is the greatest. This point is called the Efficiency Gap or E-Gap for short. When the cam opens the breakers at this all-important E-Gap point in the rotation, the current in the magnetic field in the primary coil collapses, like one side letting go in a tug-of-war contest. The secondary coil, wrapped around the primary coil, receives the benefit of this dramatic and very fast change in voltages and magnetic flux. The result is the output wire of the secondary coil is induced to transmit 12,000 to 20,000 or more volts to the distributor, ignition harness and finally to the spark plug.

The final component in a modern magneto, to improve its reliability and service life, is a capacitor with leads connected to either end of the primary coil and ultimately either side of the breaker points. You can think of this capacitor as an empty bucket waiting for the breaker points to open. The instant the points begin to open, the electrons begin to fill the capacitor like individual grains of sand until the bucket is full. By filling the capacitor, instead of the air gap forming between the breaker points, with electrons, the points do not arc as they are opening. This is beneficial because an arc transfers a portion of the material from one side of the breaker points to the other. Over time the material could build up and reduce the effectiveness of the breaker gap. The arcing could also create heat that could melt the plastic cam followers and distort the timing of when the points would open. The capacitor is sized to give the points ample time to open before an arc can be formed.

The important thing to note in this discussion is the internal timing of the magneto is critical for optimal spark generation. The internal timing of the magnetos is adjusted either by the breaker points or cam position relative to the shaft through the center of the magnets. Wear and heat can effect part of the magneto breaker system and change the internal timing to something other than the optimal E-Gap position. For dual ignition, timing of both breaker point opening at the same time is also critical. That means that both sets of breaker points must simultaneously begin to open when the magnetos are at the designated E-Gap position Finally, the capacitor is vital to maintain the health of the breaker points by providing time for the points to open and reduce the possibility of an arc.

You can order a printed copy of Q-talk #87 by using the Q-talk Back Issue Order Page.