Q2 Plans Chapter 7 Page 7-2

- Details

- Category: Q-2/Q-200 Plans

- Published: Wednesday, 24 May 2006 09:05

- Written by Quickie Aircraft Corporation

- Hits: 5395

|

....

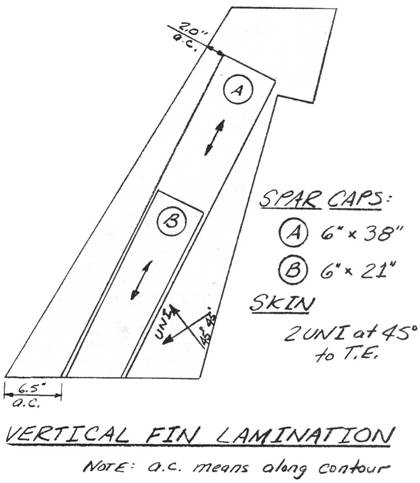

Cut all of the UNI cloth for the skin and spar caps.

.....Laminate 2 UNI at 45 degrees to the trailing edge of the vertical fin. Don't forget the peel ply tape on the trailing edge of the vertical fin trailing edge core, and remember to knife trim the leading edge at the tangent point,and to obtain glass-to-g1ass bonding in the vertical fin slot area. Next, laminate the two spar caps. Permit the lamination to set unbothered for at least 24 hours. .....After allowing the lamination to cure, you are now ready to turn the vertical fin over and laminate the other side. If you are careful when removing the vertical fin from the vertical fin female jigging template, you will be able to use the templates again in the following lamination. Check all level lines again and again before completing the jigging. .....The lamination for the other side of the vertical fin is identical to what you previously accomplished. Remember to sand down the 'tails' on both the vertical fin trailing edge core and the vertical fin slot area. At the leading edge of the vertical fin_ feather the previous glass layup. Laminate the skin first (2 UNI at 45 degrees to the trailing edge), overlapping at the leading edge a minimum of 1'1 and making a glass-toglass bond at the trailing edges, and then laminate the spar caps. Let the vertical fin cure for at least 24 hours. .....Later on, you will modify the shape at the vertical fin root so that it can 'plug intol the aft fuselage. For now, content yourself with adding a small piece of Urethane to the tip, carving it to a pleasing shape, and glassing with 1 BID, overlapping onto the vertical fin.  |

||||

END OF CHAPTER |

||||

PAGE

7-2 |

||||