Q2 Plans Chapter 3 Page 3-22

- Details

- Category: Q-2/Q-200 Plans

- Published: Sunday, 28 May 2006 03:05

- Written by Quickie Aircraft Corporation

- Hits: 5031

|

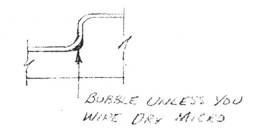

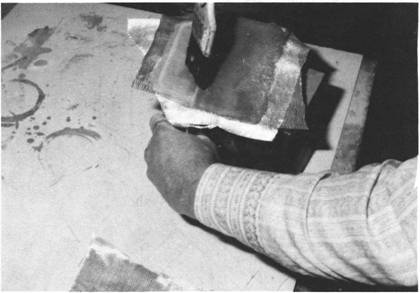

.....Mix Safe-T-Pox,

make a small batch of slurry,and save the remaining epoxy. Slurry the

foam surface and apply two plies of BID to the contoured surface. Start

the layup in the center and work out toward the edges. If you have

trouble getting the glass into the depression corners without bubbles,

lift the plies and wipe in a little dry micro. You will then find that

it will lay smoothly in without voids (see sketch). This depression

is sharper than any in your airplane and is intended to give you a

feeling of how sharply you can form the cloth.

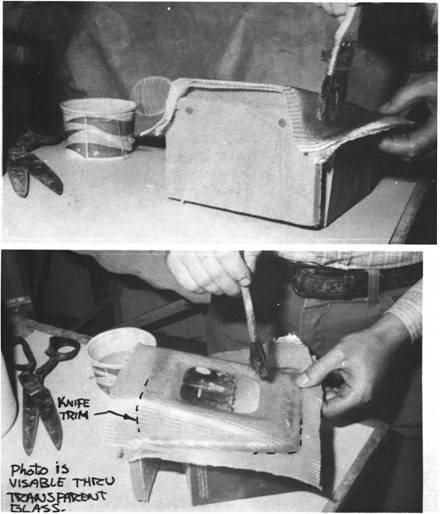

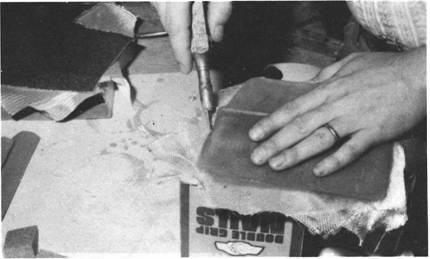

.....Before laying

the third BID ply down, place your favorite photo in the depression,

and

then lay the third BID ply over it. Scissor trim the excess glass cloth.

Allow to cure and knife trim the edges. The lower edge is trimmed flush

with the bottom of the foam block.

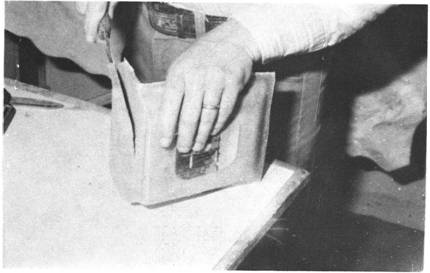

.....Wait until

the second layup is fully cured. Remove the 1 inch foam block with

a butcher

knife

and sanding block. Remove foam for a 1/4" flox corner and sand

the glass surface dull.

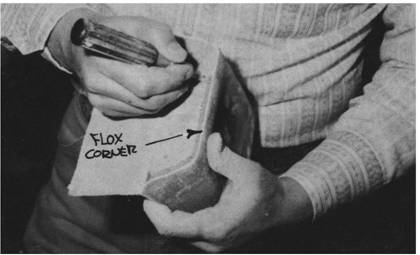

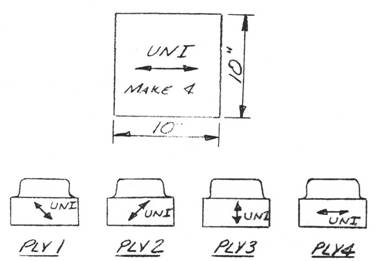

.....Mix Safe-T-Pox,

a small batch of flox, and a small batch of micro slurry. Fill the

corner with flox and slurry the foam. Lay up the four UNI plies with

the orientation shown.

.....Knife trim the

edges. After 12-hour cure, sand the edges with 100-grit sandpaper as

required

for smoothness.and good appearance.

.....It may at this

time seem a bit ridiculous to use three layups, about four hours work,

and

two days cure, just to make a book end! But remember, this book end

was not designed for ease of construction; it was designed instead,

to let you get a first hand exposure to the following operations before

starting on your airplane; glass cutting, foam preparation (slurry),

BID and UNI layups, flat surfaces, corners, and compound curves, flox

corner, knife trim, concave and convex foam carving, glass to glass

surface preparation, and sanding edges. So, use this experience to

your best benefit and spend the curing time studying the plans. Even

if you're experienced in glass layups, the book end is a worthwile

project to get familiar with the workability of this BID and UNI weave

cloth

|

||||

PAGE 3-22 |

||||