Q-talk 159 - Marc Waddelow Design Insights

- Details

- Category: Q-Talk Articles

- Published: Saturday, 29 June 2013 14:27

- Written by Dan Yager

- Hits: 8848

by Marc Waddelow, Gene Sheehan, and Jim Masal

[ EDITOR'S NOTE:What follows is an excerpt from letters sent between Marc Waddelow, Gene Sheehan, and Jim Masal sometime around Mid 1986. These originally appeared in QuickTalk 28 and I am reproducing them below so that you can get some insight into the process that went into the Waddelow design for the Main Wing and sparless Canard for the Tri-Q's.

Definitely an interesting read. In hindsight, I feel kinda' bad for Gene. To me it seems like he was trying to answer the questions, and not merely being dismissive. However, we also have many Tri-Q's currently flying with Marc's canard and main wing design. A design that Gene ultimately felt would work just fine. So I guess we all win in the end! ]

JIM MASAL NOTE FROM QUICKTALK 28:What follows are excerpts from an exchange of letters last year between QBAer Marc Waddelow of New Braunfels, TX and Gene Sheehan, with each copying me. The information will be more interesting to those of you with an interest in design.

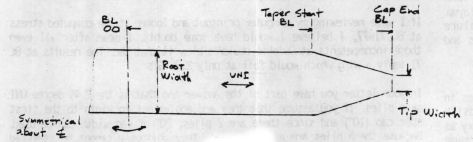

Waddelow is building Q-2 kit #2873 including a number of innovations including a DFIS, Digital Flight Information System, a Tri-Q mod and a dual rotor Mazda RX-7 engine capable of dragging the whole mess along at 200 mph. These are changes not to be undertaken frivolously but Marc has a good academic engineering background, a conservative streak and a good deal of patience to carry him along. He decided to add 20" tip extensions to boost high altitude performance, and since he needed to know how to beef up the spar cap layups he wrote a little computer program to perform the stress analysis. He found data for strength of UNI/epoxy in a hand layup and just for fun ran the numbers for the standard, per plans layup. He got a surprise: they showed the main wing to be very near failure stress at BL 40. This was calculated on a 200" span, 1100 lbs. gross and 4.6g Utility Category loading. He wrote to Sheehan:

Dear Mr. Waddelow,

Thanks for your letter. Before I recheck our design calculations and immediately issue plans changes, etc., I hope you don't mind if I check those computations of yours which I can discern.

(1). Utility category is 4.4G not 4.6.

(2). Rear wing area of the Q-2 is 31.5 square feet and not 24.6528 as you have computed.

(3). Worst case load (aft cg, gross) on the rear wing is 392.13 lbs and not 495 lbs as you have, computed.

(4). Rear wing loading, worst case, is 12.45 lbs/sq ft and not 20.0789 as you have computed.

If the wing loading were 20 lbs/sq ft the rear wing would be required to produce a coefficient of lift of 1.91 at the stall speed of 64 mph. This is impossible for the Eppler 1212R airfoil. The correct CL is 1.19 at 12.45 lbs/sq ft.

Perhaps part of your mistake is in assuming that all lift is generated by the wetted area of a wing and that none is generated by the section of wing buried in the fuselage. This assumption is incorrect. As a matter of fact some configurations will generate more CL in the fuselage section than in the wetted wing area.

The mass of the wing itself helps unload the structure and must be considered especially in the case of a Q2 canard with wheel pants, tires, brakes, etc.

Most foreign governments require load testing of every homebuilt before licensing. The Q2 rear wing has been load tested numerous times all over the world and has yet to fail. Our own testing was to about 8G.

Finally, one of the dangers of using computers (I own and use several) is in believing what they tell you. I'm sure I don't have to remind you of "GIGO".

Sincerely,

Gene Sheehan

Dear Marc,

Well, you're trying, I'll give you that. This time your air load distribution is very close to correct.

If I were reviewing my computer printout and looked at the computed stress at BL 71-77, I believe I would have some doubts. I mean after all even those incompetents at Quickie couldn't blow it that bad. The results at BL 71 imply a wing which could fail at only 2.78 G's.

In your letter you have part of the answer and that is the 2 45-degree UNI skin plies. If you assume that they are equivalent in width to the first spar cap (10") and since there are 2 plies, 20" of cap width can be used. Because these plies are at 45 degrees, they obviously cannot be stressed to the same levels as spanwise plies. Our testing indicates that you can use about 22.5% of spanwise levels. For use in your program it might be more convenient to change the width to 4.5", which would have the same result. Obviously this increase in equivalent spar cap thickness does not stop at BL 71 but continues along the entire span, root to tip. Its actual value will be larger at the root and smaller at the tip.

I didn't give you the weight of the wing before but I will now. You can assume about .14 lb/inch at the tip increasing to about .19 lb/inch at the fuselage sides. These load values should be multiplied by the appropriate G loading (4.4) and given a negative value (tending to reduce bending moment).

In your first analysis you apparently assumed that all lift loads were generated from the side of the fuselage on out which was incorrect. Your beam analysis appeared to assume that the spar is cantilevered from the fuselage side. In your second analysis the spar is assumed to be cantilevered from BL0. This is certainly not correct. Our testing indicates that the beam acts as if it is cantilevered from about BL 10.

As to stress concentrations most builders will sand the edges of the spar caps in finishing which will tend to decrease this situation.

As to fatigue problems - they don't exist.

Most companies in aerospace use computers to aid in analysis and design of aircraft. However I am not aware of any, which substitute computer analysis for testing...

Sincerely,

Gene Sheehan

Dear Marc,

...I gave you certain details regarding the Q-2 wing not to disseminate information but rather to help allay certain concerns you may have raised. My experience has shown that "a little knowledge is a dangerous thing". Some builders will try to second-guess and make changes based on some but not all of the relevant design data. I can think of two such examples, in both cases the gentlemen died on first flight attempt...

As to your suggested modifications I can't see anything wrong with them other than an increase in weight. This may seem to be a small matter to you but my experience has shown that the typical homebuilder who doesn't trust the designer and adds a little beef here and there usually winds up with a very heavy airplane. He also insists on flying over gross weight. So instead of having a stronger airplane he may well actually have less margin...

...your second analysis of the stock wing wasn't too far off, but it didn't properly allow for the twist built into the design (about 1.5 degrees). If your wing extensions continued this wash out we have one situation. If they merely continued the AOA at BL 100 we have quite another. In either case I suspect structural problems.

If you will review the canard structure you may get a glimmer of what I'm talking about. You will notice that we have added a compressional stiffner. This was found to be necessary by testing. What happens without this stiffner is a failure due to local buckling. This is in spite of what appears to be adequate spar caps. Ideally the shear web on the canard could be about .30 further forward. This was done in order to make the surface easier to build. Even with this stiffener when the canard fails, it fails in compression again due to local buckling. Spar cap analysis would predict a tension failure but it doesn't happen that way.

If you have not added a compressional stiffener or moved the shear web or added an additional shear web you will almost certainly have a problem. Even if you have made modifications the results are difficult to predict.

I can think of no alternative to load testing. I urge you to load your wing to as least 50% above what you wish to use as your limit G loading. At Quickie we don't even taxi a new airplane that has not been load tested.

Finally, I must insist that you call your airplane something other than a Q-2...

Sincerely,

Gene Sheehan

JIM MASAL NOTE FROM QUICKTALK 28: As this is written, Marc has successfully sold his carbon fiber spar and is busily laying up both his main wing and a sparless LS(1) canard for his Tri-? according to the schedule his analysis defined.