QUICKIE NEWSLETTER 15 page 5

- Details

- Category: QAC Newsletters

- Published: Tuesday, 05 December 2006 14:12

- Written by Quickie Aircraft Corporation

- Hits: 13506

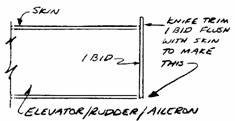

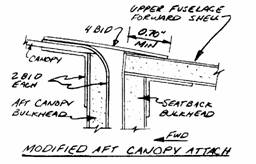

| Q2 PLANS

CHANGE NOTICES NUMBER: Q2PC2O DATE: 4 December, 1981 Each end of each elevator, aileron, and he rudder should be capped with I BID and a Box corner all the way around the outside skin. An alternative method is to brush micro onto the bare foam as a seal. Either of these two methods should be accomplished before priming and painting but after final trimming of the lengths of the control surfaces and trial fitting to the canard, wing, and vertical fin, See sketch included here.  NUMBER: Q2PC21 DATE: 25 January, 1982 Modification to the Aft Canopy Attachment; Page 13-4; Attach the aft canopy bulkhead to the canopy with 2 BID inside and outside, as shown, prior to fabricating the aft canopy seal from 4 BID. The original drawing on Page 13-4 showed a very short length attachment on the outside (i.e., aft face) of the aft canopy bulkhead.  Q2 BUILDER TIPS Q2 Plans Addendum sheets i through xii should be in the hands of each builder. NUMBER: Q2BT29 DATE: 15 January, 1982 Quickie/Q2 Tiedowns—When going cross country in QAC’s Quickie or Q2, we try to leave the aircraft in a hangar for overnight parking. If that is not possible we use the standard tie down rope to loop around the tailspring for security. By securing the tailspring firmly to the ground, we find a minimum tendency for the Q2 to become airborne, even in high winds. One could also fabricate ring type nuts for each axle end location so as to use the standard airport wing tiedown ropes. |

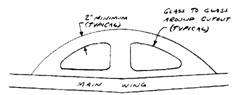

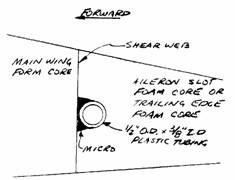

NUMBER: Q2BT3O DATE: 15 January, 1982 Upholstery—Many builders are opting to make their own upholstery rather than to purchase the available upholstery option. One must size the upholstery to fit the frame of the pilot. Be sure to provide access to the baggage compartment behind the seat. NUMBER: Q2BT31 DATE: 15 January, 1982 Baggage compartment—Use netting across the FS 94 Bulkhead and foam fiberglass panels to isolate all flight control parts if it is planned to place loose objects in the baggage compartment. Instead, tie down straps could be installed. NUMBER: Q2BT32 DATE: 15 January, 1982 Overwing Storage Compartment—If desired, two cutouts may be made in the upper seatback bulkhead to gain access for storage to that area over the main wing center section.  NUMBER: Q2BT33 DATE: 25 January, 1982 It is recommended that navigation/position lights be located in the tips of the main wing if a builder desires to include this feature on his aircraft. The sketch included here shows the recommended routing of the conduit for the wires through the main wing. Mount the plastic tubing with dabs of 5-MIN and fill the void with micro.   |

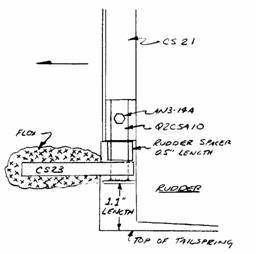

NUMBER: Q2BT34 DATE: 26 January, 1982 Removal of the Rudder; Page 14-2, The sketch included here indicates that approximately 1.1” separation between the bottom of the Q2CSA1O and the top of the tailspring is needed in order to remove the rudder once it has been mounted to the vertical fin. To remove the rudder, remove the AN3-14A bolt and drop Q2CSA1O down. This will allow the rudder to slip off the pivot so that it can be removed from the aircraft.  NUMBER: Q2BT35 DATE: 26 January, 1982 Q2 and Quickie prefabricated fuel tank; This fuel tank is manufactured with the forward face about 3.5” higher than what is shown in the basic plans. This fact will allow more fuel capacity, if desired. Be sure to check first pilot and passenger legroom, particularly if you are tall. It may also be necessary to build a tunnel for the pitch control arm. The builder can, of course, use the plan provided template to reduce the fuel tank height to the standard figure.

|