Q-talk 32 - LETTERS & TIPS

- Details

- Category: Q-Talk Articles

- Published: Friday, 28 February 1992 06:11

- Written by Tom Moore

- Hits: 3714

Jim

I had a problem with my Tri-Q (C-85) that really caused me a great deal of concern earlier this year. My engine would lose almost all power just after reaching three to four hundred feet agl (about the time there is no more runway). A lot of people gave opinions about what it might be, but none really hit on it. The most common opinion was carb ice.

Since I could not get it to quit during any kind of static run-up, I decided to put a temp probe in the carb box to see if indeed it was ice! I have a device with two probes, so I put one in the carb, and the only place handy for the other was inside the insulation for the fuel line. Now I was armed and ready for anything, or so I thought. Hell, I could adjust the heat when it started to ice up. Well, I took off, watching the temps, wondering why the temps were normal, then I checked the other probe, it showed 150 degrees and climbing. About this time the engine started running rough and I was out of runway. I managed to make it back around and land (WHEW! I thought I was going to earn another black hat.)

I shut it down, hurried out and stuck my hand in through the cowl flap to verify the heat in there. The carb was so hot I almost burned my hand. I really didn't believe the temp gauge.

As it turns out, I had previously removed the cowl for painting, and there was a small opening (about 1x3) just below the carb that had been covered, but was now open. Apparently, there is enough "pressure" here to prevent any air from escaping the cowling. It was getting so hot inside the cowling that the carb was cooking (boiling) the fuel. On the ground, enough air was flowing, but once airborne, it couldn't.

All changes are important, if you can't keep up with them, WRITE 'EM DOWN.

Mike Conlin

Dear Jim,

Since I am a Q-2 builder living in New England near the sea coast, I have been very busy of late building a Quonset hut in my backyard to shelter my Q-2. The dangers to these little birds brought on by the harsh weather etc. were brought home to me in a recent Q-Talk so I decided to act quickly and recently completed my mini-hanger. I now have a local boat builder helping me with the project but, sorry to say, have little progress to report over the past year. The project had to be moved from the garage I was renting due to foreclosure of the property and with the coming of the New England winter and the need to find shelter ... (you can guess the rest). I would like to commend you on the fine job you are doing keeping us all motivated and passing along all those excellent tidbits of information.

Thank you,

Jerry Jerome

Dear Jim

I completely agree with all the nice things the other guys say about Q-Talk. However, contrary to what some of the other guys are doing, I really concentrated on my Q2 this past summer. It is now ready and raring to fly.

By way of review, I first flew it in the fall of 1989, getting about 15 hours time, but then made a low (understatement) approach and cleaned off three approach lights which I didn't know were up on poles. This demolished the prop and canard, and was tough on the cowling and underside of the fuselage. I credit the composite construction with saving my butt. My tip of the month: Shoot for the thousand foot runway marks - never for the numbers.

Then with help of Fred Wemmering, I found and bought a canard from Sherm Hanke, but it took me two years to get it all back together. In November the Q2 was returned to the Altoona, PA Airport and made a couple of fast passes down the runway, but I needed some small adjustments before I was willing to be airborne.

Now the excuses, from November until Christmas the harvest of Christmas trees gets top billing at our house, and after that the emphasis shifts (if I wish to stay in the good graces of the lady of the house) to our annual trek to Sanibel, FL. And so 244GB sits in the hangar waiting for my return and a nice spring day. I am confident it and I can get our act together.

Jerry Barker

Ed. Note: Yippee, Jerry glad you are back in the saddle. Am also glad you are taking your time and being patient.

Dear Jim

Glad to hear (hopefully) that you will be hanging in there for another year. It seems that the road to completed aircraft is fraught with many obstacles. The latest was the decease of my '76 Datsun pick-up. Naturally when it broke down, I did the American thing and bought a new car that I couldn't really afford! Doing my part to help the economy don't ya know! Living in Southern California, we are not allowed to leave cars outside (where thieves break in and steal), especially new ones. So I now have two cars in my two car garage.

However fate has not been completely cruel to me. Guess who just joined my local EAA Chapter? Norm Howell! As I am sure you know, this guy is a tremendous blessing, not to mention a real inspiration.

Anyway Quickie S/N 415 will mostly be hibernating during the cold months, which fortunately don't last long here. Then I am sure I will be testing the theory "slow but sure wins the race". Maybe I will pick up a partner along the way. Anybody out there want to be half owner/builder living close to Lancaster, California? Also, if anyone in the southern California area has a flying Q2 and would be willing to give me a ride, I would be more than happy to buy gas!

Michael P. Menke - (805) 942-1868

Dear Tom

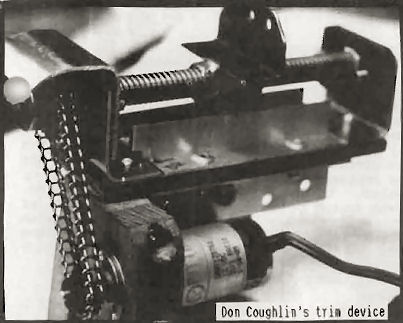

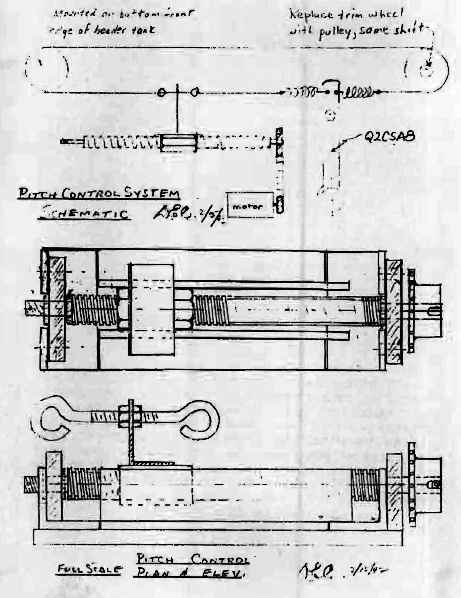

In response to your telephone call, I'm enclosing a schematic diagram and a couple of drawings of my pitch control mechanism. I hope this idea will be of interest to some of your readers, as their ideas have been to me.

Below are copious notes in lieu of dimensions on the drawings.

1. Refer to photograph for general view. Some details (obvious fasteners etc.) have been omitted from drawings to avoid muddying the waters.

2. The screw is 1/2" O.D., 10 threads/inch, square thread, overall length 7". One end is turned down to 1/4" O.D. X 3/4", Thread 1/4 - 28 x 3/8" and drill to receive a castellated nut & pin. Opposite end turned down to 1/4" x 1", leaving 5 1/4" of 1/2" - 10 thread. Non-threaded end is flattened at outer end to accommodate pulley set screw.

3. The nut I bought with the threaded stock is 1 1/4" long, hex., which allows total travel of 4" end to end.

4. Bearing blocks are Micarta (laminated phenolic) 1/4" thick.

5. Thrust load, both directions, is taken at threaded end of the screw. Note washers on both sides of Micarta. The castellated nut must not be tight, allow for lube.

6. I used 1" x 1" x 1/8" aluminum angle for the bearing supports and for the side rails; the latter serve to prevent the nut from turning with the screw, and must clear the steel angle to which the cables are terminated.

7. The steel angle 1" x 3/4" x 16 ga. homemade, is brazed to the steel nut.

8. I ran the nut back and forth many times with grinding compound until it ran smoothly without binding.

9. The chain I used is stainless steel 3/16" pitch ladder chain. Sprockets are Boston Gear, 12 tooth on motor, 1/8" bore, and 20 tooth on the screw, 1/4" bore.

10. I mounted the assembly on 1/4 plywood.

11. The motor is a Pittman Model 8312 with a 31:1 gear ratio, giving a no-load speed of 240 rpm at 12 volts d.c., the stalled current is 2.8 amps. The screw speed, with no load will be 144 rpm, giving 8.3 seconds for travel from mid-point to either end. The time under load will be longer. Normal adjustments are expected to be less than two inches.

12. Control consists simply of a two pole, double throw toggle switch with spring return to mid (off) position.

13. I put a guard over the screw sprocket to keep stuff out of it.

14. Align carefully so bearings won't bind.

15. Motor shaft is off center, so chain adjustment can be accomplished by rotating the motor in its mount.

Don Coughlin, San Ramon, CA

(510) 828-2418

Dear Jim

You may remember me, we met at the Kerrville fly-in in 1989. I had the Q2 that used to be in South Dakota. I told you that I would write an article for the newsletter. Here it is, a bit late, but here it is.

I have now moved back to South Dakota, that is part of the reason the article is so late. I had a lot of fun flying the Q2 around south Texas. I had the plane hangared at Kleeburg Airport 10 miles west of Kingsville, TX. I had to drive 50 miles one way from Corpus Christi to go flying. The hangar rent in Corpus Christi was prohibitive, besides they have no T-hangars there. The plane flies well, I have vortex generators and a reflexor. I notice very little pitch down in the rain. I have never flown it without the vortex generators so I don't know how much good they actually do. We had a T-tail on it at first. We didn't feel that it was useful so we took it off. The "we" that I am talking about is James Fletcher, my partner. Jim and I spent a little over three years building it in my garage.

We have had lots of problems with the Revmaster 2100D engine. We have to adjust the valves every six to ten hours. The head bolts seem to loosen up also. It seems that we are always adjusting the mixture. Always trying to get it a little bit better. We have the Revflow carburetor. We had a Posa at first. They both worked about the same. We replaced the cylinder heads with the 75 HP heads at 43 hours. The cylinders were cutting into the heads like a cookie cutter. They told us at Revmaster that the original heads were made out of too soft material and the new heads would stop the problem and the valve adjustment problem would be fixed also. The new heads didn't stop the problems.

My wife and I flew the Q2 to Shawnee, Oklahoma once. On the return flight when we landed in Sioux Falls and taxied up to my hangar and shut it off, oil was pouring out. The block had cracked in an oil galley. I had 75 hours on it. We shipped the engine back to Revmaster and they replaced the block at no charge. All it cost us was the freight both ways, which was substantial. If the block had cracked while I was flying it would have pumped the oil out in a short time. That may have been disastrous.

I now have the engine down for major repair at 190 hours. The cylinder heads are shot and must be replaced. The pistons and cylinders are fine. I haven't split the cases and inspected the bearings yet, but I expect them to be OK. I am very seriously contemplating installing hydraulic valve lifters at this time. There is a company from California that makes them for the beetle engine with no machining necessary. This is getting to long, so I will stop here. I will write another article of my return flight from Kingsville to South Dakota.

Thanks again,

Jerry Kennedy

Ed Note: A late report but well worth waiting for, Jerry. I'm hearing good stuff about hydraulic valve lifters from the Dragonfly newsletter.

Dear Jim

You have probably heard all the excuses but here is mine anyway. I had my check all ready on time, but somehow instead of the post office, it ended up with my daughter's papers on her way to college in West Virginia. A fresh one is attached and I hope all is forgiven. (NO! Ed.)

I finally got my TQ-2 82BD in Houston, flew it around the patch two times. The third time, I ran it off the 100' runway and ended upside down destroying the prop, spinner, front strut, tips of the canard, canopy, cowling, the tip of the vertical stabilizer. It did not do much good for my ego either. I walked away under my own power after I was pulled out of the mess. I will write you soon about why it happened.

I am a composite illiterate but stubborn as a mule. I have already started with the engine and will get to the airframe as I learn how to do it or find experienced people to help me. I hope to have it flying again in a year or so.

Much thanks for keeping the QBA together and Q-Talk going. I am sure it means a lot to us members whether we can express it properly or not.

Sincerely,

Atakan Sobay

Ed. Note: I'm not an E.Z. forgiver, but geez am I compassionate about your accident. Bravo for you continuing on.

Dear Jim

I have flown Quickie Tri-Q200 GBMFN for over two years now from 650 meters at Elstree Airport, England. The Scott Swing Tri-Gear makes it very easy to handle. I can turn around in less than half the runway width, brake hard, land on grass, so easy compared with the stories I read about the tail wheel version. I went from a Bolkow Junior to Tri-Q with no problem at all.

Adrian Webster

Dear Jim:

The check is in the mail. Delighted to learn that you are able to continue the excellent publication we all enjoy.

I will send you pix as soon as the weather in Minnesota warms up enough for me to get the Tri-gear mod painted. Still winter up hear, yo'all. I have also just completed upgrading my Revmaster to the 75 hp heads and am looking forward with lots of anticipation to see what new numbers will emerge. As you know from other testimonials, the tri-gear mod is beautiful. Scott did a great job working this out. Am looking forward to lots of flying this summer after most of last year spent in tweaking and modifications.

We did a lot of work getting the various antennas located so as to produce the desired results. Com/Nav; Transponder; Apollo 618C Loran and if anyone wants to call me I would be happy to share my experiences for whatever they may be worth.

Keep up the great work and hope to see you in Sun-N-Fun. I'll be the old man in white skin from the north regions.

Sincerely,

Walt Halloran

Ed Note: He was there - looking for all the world an albino! Any of you guys have some input on successful/not antenna installations? Lemme know please.

Hi Jim, met you at Oshkosh at the back porch seminar. I'm building Q2 #2594. Still filling and sanding, seems like an endless job, top is finished, have it turned over and working on the bottom. Removed the wheels and pants. Seems the right thing to do; now all I have to do is find plans for the tri-gear. I will have to contact the members who have made the change. Things would go a lot faster if I didn't get this epoxy reaction. Be glad to get to the mechanic work, so I'll keep plugging away. Appreciate your efforts with the newsletter, lots of good hints.

Gordon Hanson

Dear Jim,

It's now over two years since I have purchased my Q-2. I never started building, except for some test-pieces and hot wiring, because I was always moving around in whole Europe for my former company. Now I have settled down in Switzerland. I set up a nice workshop in an old disused cowshed on a farm. On October last year I really started construction. So far I did all bulkheads, main tank, ailerons and the rudder. By the time you're reading this letter I should have finished the elevators. And if all is working fine, I will start construction of the main wing around March.

Because of our weather in Switzerland, I am using an epoxy system from Ciba-Geigy (Araldite LY5052 and hardener HY5052), which you can use in lower working temperatures (64-77 F is enough). It is a common epoxy in Switzerland's home builders scene and approved by our Swiss FAA.

Some time ago I contacted Gerhard Gubler, he is the only one who is flying a Quickie in Switzerland, or I should say was. On the way to an RSA meeting (EAA) in France, he experienced the wake turbulence devil on landing, which resulted in a broken canard. He is planning now to convert to a Rotax, and will install a LS canard during restoration he said. I am still in contact with Rudi Brandenberger from England. We do a lot of talking about building problems, and, of course, a lot more hangar flying, which keeps you going on.

At this point I will say thank you very much for your superb work as QBA chief and editor. I am really happy that they got you convinced again. You are doing great work, your Q-letters are never tedious, and there is always a bunch of good info and something to laugh at. Keep it going like that.

I don't know if I will make it to Oshkosh this year, it would be my 4th time. But meanwhile I wish you many happy landings and all the best.

Jack Kofler

Ed Note: You Swiss guys really have it tough. Rudi Brandenberger, a station engineer for Swissair based in England, just sent photos of his crated wing that he had to airlift to Switzerland for load testing. And we think that we have FAA troubles! Press on Jack and Rudi, we're all cheering for you guys.

Dear Jim;

Well finally, another Q-2 bird becomes free of its earthly confinement as on 20 October 1991, C-GGFD Q-2 #2028 went aloft on her maiden flight at Mountain View, Ontario. The test pilot was Lt. Col (ret'd) Fern Villeneuve who stayed in the air for a little over fifteen minutes. The aircraft handled well and according to Fern "it goes like a bullet!". Other than some minor rigging adjustments, everything appears superb.

Initial flight tendencies indicate some left wing "heaviness" in addition to feeling a tad nose heavy but otherwise controllable without any apparent undesirable divergent tendencies (so far). 3000 RPM on the Westach yielded 155 MPH IAS. The ensuing low level "photo pass" on the fifth circuit looked great! The C of G will be double checked on a new weight and balance while some re-rigging has already been affected. I've also enclosed some snapshots plus a slide for your gallery.

My aircraft is operating with the stock Revmaster, GU canard, Tee-Tail but no reflexor, and the uni-control/actuated hydraulic brake system. I would very much like to incorporate a dual actuated brake system over the winter months, additionally, the control arm to the elevators is as per plans with the single tube/eyelet and universal joint assembly, which makes individual flight surface adjustments a pain in the butt. If any of the veteran Q-2 drivers can offer any assistance in the form of suggestions and/or schematics for these items, it would be greatly appreciated. Other desired information includes sparrow strainer plans and installation criteria, vortex generator size and positioning data, recommended carb-heat assemblies for the RevFlow and a part # plus a source of supply for the kit supplied voltage regulator.

Anyway, I'm really looking forward to meeting some of you diligent and colorful individuals who have kept the "Q" movement alive and well, at one of the future fly-ins in '92. With #2028 in the air, the possibility is now becoming a probability. Cheers!

Greg Merrill

P.S. Jim, if you have an address/phone # for the owners of C-GOTU and/or C-GMBK from your Oshkosh survey, could you please forward the info? I'd like to touch base with both of them, if possible.

Ed Note: No gottee, but if they read this they can contact me and I'll do a handoff to you.

Dear Jim

Enjoy the newsletter as much as ever. Haven't flown 31BS much this last year (about 125 total now) since I am able to fly a Mooney and a Cubby anytime I want to. Have been spending most of my time working on my R. G. Glasair, hope to get it in the air this year.

Bob Stark

Dear Jim,

We have three Q2's flying in Montreal, all with the common problem of rapidly deteriorating exhaust systems. The pipes are rusting through! Does anyone know a source for replacement exhaust pipes for the Revmaster engine? Revmaster will not supply them. One source said he would custom build the system for about $1200, a little more than I would like to spend. Also, the pipes should be stainless steel for durability and weight. I have had mine chromed at a cost of $180, which hopefully will extend the life somewhat. But, I expect to be looking for a replacement sooner or later.

On the subject of toe-in vs. toe-out, I have heard another explanation from a respected engineer. He is of the opinion that toe-out will exacerbate high-speed ground handling problems. His theory is that toe-out will cause additional drag on the wheel that is on the inside of the turn, thus turning the aircraft more. This is true because the inside wheel is trying to go in a direction at some angle different from the direction of travel of the aircraft, and the resulting "sideslip" causes drag. At the same time, the outer wheel will cause less drag if it is heading closer to the direction of aircrafts forward motion.

My personal experience with toe-out involved my fathers 1959 Mercury. I bent the steering tie rods while turning a corner over railroad tracks. The rise of the hill obstructed my view of the road and I hit a curb. Anyway, the wheels were heading off in different directions (still attached to the car) by what must have been close to 10 degrees toe-out. This had a rather adverse effect on handling. The steering wheel wanted to go off to one side or the other (equally). It was opposite to the normal condition where, if left alone, the steering wheel would come back to center. For anyone who believes toe-out will help to keep a Q2 on the center of the runway, I suggest trying a temporary adjustment to a cars alignment to experience the instability. When I saw the suggestion to add toe-out, it didn't seem right, but we made the change anyway. This winter it's going back to straight ahead, if not slightly toe-in, as is the case on Piper tail dragger aircraft.

Yours truly,

David Cyr

Ed Note: Oooops ... here we go again resurrecting a problem already put to bed. In my opinion the article submitted by Fred Wemmering, many moons ago is definitive. Do what you want, but so far nobody flying Q-2's is passionately arguing for toe in and a few who changed to toe out are happy. A big consideration is getting toe-out or neutral under flight-loaded conditions. This ain't a '59 Mercury. I follow the guys actually operating them.

Dear Jim:

I did not have a chance to slip in a note about progress and events with my yearly renewal so this is it.

A lot of things have been happening in this area for me since Captain Norm Howell showed up. A number of us EAA types out at the B-2 Combined Test Force at Edwards had been talking about a base chapter of the EAA, separate from the Chapter 49 in Lancaster, California. It just so happened that the average age and level of building in the old chapter didn't agree with a lot of the personalities that are residents at the base, and besides it would be closer for military and civilians employed at the base. Well, in steps Mr. Howell who proceeds to wink at a number of us "hell bent for leather" guys and says we are going to take over the Lancaster, California chapter as soon as he gets out of Test Pilots School. At the same time, a number of young captains decide over bad tacos at the O'Club to try to start up a base chapter. Norm gets in on this and sets us up for meetings in the Test Pilots School Auditorium. So at this time Norm is on the Board of Directors and I am the secretary of what is to be the EAA Muroc Chapter 1000. We have more than 40 members signed up and had Mr. Alan Tolle, the RV builder, come out and give us a talk at the last meeting. There were several attempted coups last year on the world scene. As far as I know, only ours was successful.

Anyhow, if you get out this way, check out Norm's hangar at Fox Field in Lancaster (Hangar 308). In addition to his Long-Eze project and his partner Bob Waldmiller's Corby Starlet project, there are almost two complete RV-6's hanging from the rafters. Evidently a couple of F4 Rino drivers rescued their RV birds from the horrors of Mount Pinatubo (Clark AFB, Philippines) and found out Norm had "a little hangar space". Norm is quite a guy.

Enclosed are some pictures of Scott Horowitz's Tri-Q200. He is a young test pilot out at Edwards (805-258-6945) and has been building in the dark for some time. He has got a lot of good ideas. Scott has been through one high speed on runway accident with the aircraft and has since repaired the plane. He may attempt a flight within the next four weeks. Scott also has a real neat compact disk player installation.

My tail dragger Q-200 is a good bit behind schedule as it has taken me much longer than I originally expected to surface prep and wet sand primer on to this airplane. It also hurts because I am doing this all by myself. The only thing I can get my wife to do is help me move the big pieces around when I need to reorganize.

Modifications and improvements to the airplane recently are as follows:

After difficulty getting the fit I wanted with an aluminum instrument panel, I fabricated a panel out of compression molded fiberglass and Rohacell foil. A central console was built in the panel to allow the avionics stack to be mounted without cutting into the header tank.

I am preparing an Aircraft Spruce Two Lever Throttle Quadrant for installation in the right hand pilot console. I have modified the quadrant by removing the upper black plastic knob from the throttle lever and replacing it with a three-inch turned aluminum handle with a momentary switch mounted in the end for push to talk function. Mounting of this handle required the welding of a hollow threaded bolt to the throttle lever to allow the handle to be screwed on and off. Norm Howell seems to think that I should remove the red plastic handle from the mixture lever and replace it with some sort of turned aluminum fixture as well.

I decided to provide an access panel to the back of the control stick location in the center console area. This is provided by hinging the top of the console using the piano hinge material originally provided in the Q-2 kits. I wanted to be assured of good access to torque tube and wire runs and wanted to avoid having to cut into and then repair a fiberglass/foam structure. I see this as a maintenance and inspection area which needs more attention.

I am having a devil of a problem assuring uniform closure of the canopy leading edge using the front hinge configuration. I intend to use two Dzus latches on each side of the canopy to hold it down flush. When I bought my kit, the gas cylinders for counter balancing the canopy were included, but I had no studs to mount them on. The hatch back type gas cylinders had what appeared to be a Ford part number printed on the outside. The Ford stud is referred to as a "retainer" and has P/N E89Z-1141836-B. A similar Jeep Cherokee hatch back gas cylinder stud has P/N 55001430 and is called a "ballstud". Both of these studs are metric and require 8 mm hex nuts. I am using both types of stud, the Jeep type tapped into my canopy swing hinges and Ford type secured to the bottom header tank stand-offs with 8 mm nuts.

Good luck in the New Year. I've got to finish this plane for Oshkosh 92! Cross your fingers.

Brian Martinez

Ed Note: Ahhh ... my old nemesis Martinez ... only I didn't find a thing to carp about in this letter! Thanks for the interesting update on some "secret" Mojave goings on.

Dear Jim, January 15, 1992

Here's the good news, enclosed find $20 for a year's dues. I have really enjoyed having QBA to read. As soon as I get it I read it from front to back. Keep up the good work!

Now for the other news. On Dec. 11, 1991, Q1 N1V bit the dirt. I was flying at pattern altitude approximately 3 miles south of the airport when the Onan seized up. I slowed up my airspeed to 80-85 to get the best glide possible, but I just didn't have enough altitude to make it to the runway. I had my choice (?) of a plowed field or a nine-foot ditch that ran between me and the runway. Well, I chose the field although I didn't get to land the way I would have preferred. I did get it down the best I could, I think. I don't remember very much of the flight or the crash, but I was able to walk away from the wreckage with very minor injuries. The doctors thought I had brain damage but I assured them it wasn't from the crash.

Anyway, the front main bearing seized to the crankshaft, hence locking up the engine. The oil passages were open and I had oil pressure prior to it seizing, so I'm still not sure what caused the bearing to seize.

The FAA came down and we took the engine apart but still don't have any answer as to why the bearing failed. They (FAA) have cleared me of any wrong doing and declared the crash as result of an engine failure.

I haven't fully decided what to do about N1V, although I would like to rebuild it! Right now I'm like Jinx, "I'm just happy to be here".

Thanks from "one of the new guys".

Bud Starnes, Mt. Vernon, IN

Dear Jim

My Quickie N5425D has almost 100 hours now. That averages to about 35 hours per year. I am still using the Onan engine, no problems so far. I would like less vibration and better climb performance. Just can't justify the cost of installing a Rotax for the type of use my aircraft gets. I am just keeping my eyes open for a used Rotax and will consider installing if and when I find one. Keep up the great work.

Arden Krueger

Ed Note: J. P. Stroud gave the Onan a strong vote of confidence by his Sun 'N Fun 100 performance.

Jim

My Q1 project (#1049) is complete except for U.V. barrier and paint. An aileron reflexor has been installed as per the 1984 Q-Talk, #17, pg. 6. Also an ignition retard system from Q-Talk 1985 #21, p. 7

The following tip, which worked well for me, was to cover a micro filled area with dry micro balloons. After setting has taken place, brush the dry micro off (save for future use). The area will be easier to sand down.

Thank you for the world's best Quickie newsletter.

Wm. E. Fisher

Ed Note: GREAT! Now for your happy report on the result of those mods, eh?

Hi Jim

Just a couple of lines to bring you up to date on things on the home front. We (gotta give Norm Howell some credit here) won a very nice plaque for "Best Composite" at the Camden Air Show in Camden, Arkansas last October. I have 17UQ in various stages of disassembly right now, working on a few new things. To include a great looking custom made full castering tail wheel, much improved brakes, and my new computer matched prop is in from Prince Aircraft, (same pitch but 8" longer - 53" x 53"). I'll let you know more as I get it ready to fly again. I've decided to convert my Onan Quickie to a Rotax 503 before selling it. That will be my next project for some time shortly after the first of the year.

Jerry Homsley

Ed Note: So, let's hear more about the much improved brakes.

You can order a PDF or printed copy of Q-talk #32 by using the Q-talk Back Issue Order Page.