Q-talk 25 - Q-NEWS - LETTERS - Q-TIPS

- Details

- Category: Q-Talk Articles

- Published: Monday, 31 December 1990 06:11

- Written by Jim Masal

- Hits: 2324

Dear Jim:

Here's another pitch to check your outboard elevator pins on pre-flight. Mine were both loose (radial play). When I removed both elevators I found both outboard pins were loose. The nut had backed off. I tightened them and used Loc-tite. Suggest builders use two nuts, lock washer and Loc-tite; and flyers preflight the outboard elevator pins for radial and lateral play. You don't want to loose an elevator!

I've only flown once since sawing off the canard and re-mounting it leading edge up 5/8". This raised the angle of incidence 1 1/2 degrees down elevator at cruise. I now cruise with the elevators in trail. I'm not sure how much airspeed I gained. The pitch buck stayed the same (65-68 power off). It would have been much easier to do this on a Dragonfly where they use shims and don't glass the canard to the fuselage.

Dave Naumann, Enterprise, AL

Dear Jim,

Q2 84JS has 330 hours on it, and has taken 120 different passengers for rides. This past fall it received first place in Iowa's State's school spirit contest because it is painted cardinal and gold the school colors.

The original oil cooler supplied by Revmaster began leaking near the aft right outlet and had to be replaced. It cracked because I had been draining the cooler each time the oil was changed by removing the hose from the aft fitting. The torque from removing the hose caused the crack.

Thanks for your willingness to continue to edit Q-TALK. The information is very worthwhile, even to those of us that have been flying their projects for several years.

John Schnackel, Fort Dodge, IA

Dear Jim,

Here's my membership renewal, no time to write much of anything right now, but I have moved and would like you to print my new address and phone number. I do enjoy hearing from people around the country and talking about these wonderful little airplanes. Over 400 hours on Q-200 89BW and still having a ball.

Barry Q. Weber, 4163 Tanager Common, Fremont, CA 94555

(415) 797-7259

Jim,

I had a rather humbling experience last weekend, (Translation - Got the shit scared out of me.) Some local aviators bought a Q200 - but insurance was not available unless they got a check out by a CFI with at least 25 hrs. in type. (The insurance company didn't think they would be able to find one! Ha - there was one right next door - me!)

To make this as short as possible - all had been checked out/signed off but one, and we were almost there. We had flown to Hearne - 7,000 ft. x 150 ft. runway, no traffic, everything working fine! We were going to do one more landing before going back to Houston. (Mind you, no controls on my side!) We made the approach, flare, and were rolling out when all of a sudden the plane takes a turn for the pasture. At first, in a medium voice (we had intercom), I began suggesting, "left rudder". I felt like a Drill Sergeant - "more left, more left rudder". But all this wasn't working, and as a last ditch effort by the pilot to "steer" the plane with aileron (guaranteed to help you in the direction you don't want to go), I could tell we had a rough ride ahead. After the dust settled we got out to survey the damage. Fortunately, the only damage was to the paint on the vertical fin. - The tailwheel assy. had broken off just forward of the pivot and was still with us because the cables remained intact. This could have been a lot worse - for the plane and us. The plane that I now fly was heavily damaged because a 50-cent nicropress sleeve let one cable slip. Two thoughts here - It goes without saying that a good preflight is essential to your well being and even though we lost directional control - aileron steering could one day make or break your airplane - don't be complacent or you might otherwise ruin your day and a fine airplane!

Dear Jim,

I have 210 hours on the Tri-Q now and I think most of the bugs have been worked out.

The plane only made it to 1 of the 3 major world events (Sun 'n Fun, Oshkosh and the Springfield Flocking) but that was the fault of the weatherman and not the aircraft.

Are any of you brave souls out there flying these things on instruments?

I flew in the rain for the first time last week and encountered a minor pitch change in the nose up direction. I was entering the ARSA and didn't have much time to play so I trimmed it out with elevator trim. After landing and thinking about it I should have reflexed the ailerons a degree or two in the down direction. Apparently the rain degrades the lift on my main wing more than the canard. It may be a while before I get to experiment with this again, wooden propeller ya know.

I am presently lacerating and abrading the cowl trying to cut cooling drag.

Next project is upholstery. I am still riding on lawn chair pads.

Larry Kehler was up from St. Louis for a look and chat session in Sept. and is going to resume building soon.

My ex-partner Weishaar is flying the hell out of the N3 Pup he built and is looking for another project.

All of you builders in the dormant stage get busy. The end product is worth the work, only 400 man hours ta build it ya know.

Jim Doyle, Spfld., ILL

Dear Jim,

The time of the year again. I am enclosing my financial dues as well as a small technical contribution. The summer has passed by very quickly and we are again snowbound. My greatest progress for this year involves a move from a 16x22 ft cluttered-up workspace to a much larger 24x36 heated area. Oodles of space until the Parkinson's Law catches up again (garbage expands to fill the space available). On the downside, the place set me back substantially and it may take me a few years to recover enough to be able to buy the 0-200 margarita mixer. Fortunately, there is a lot of ground to cover before I need it.

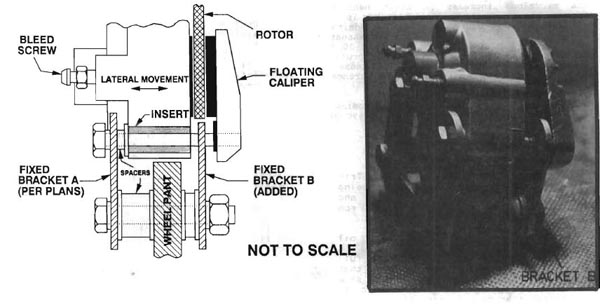

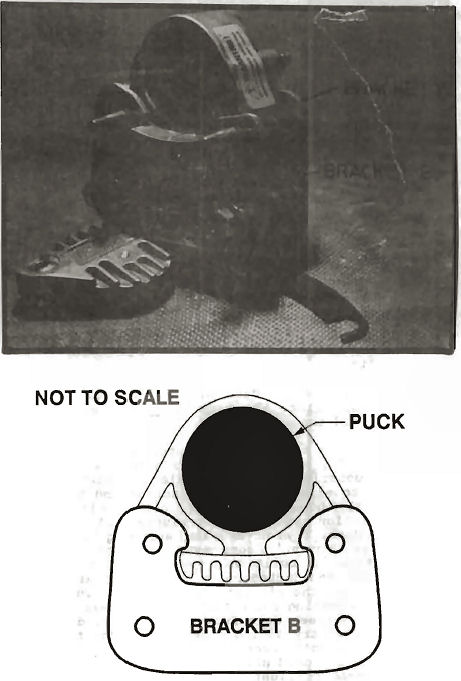

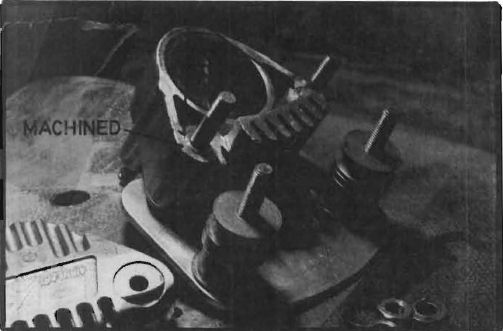

I have done some more work on the brakes this year and will try to share it with the readers. The original installation was done as per plans and needless to say, I was not very happy with it. Since I had spent a disproportionate amount of time on that installation, I decided to modify the design by adding a second bracket that would absorb the twisting force produced by the rotor (BRACKET B in the drawings). For this purpose I had to remove a part of the aluminum body around the two bolts that hold the brake assembly together (see photographs). This exposes a portion of the bolt along which the assembly can slide laterally in the bracket B. It is important that the pucks be parallel and therefore metal inserts (cylinders machined out of aluminum with a tight-fitting hole for the bolts) were permanently tapped into the brake body (see photos and drawing). I have avoided giving dimensions for the individual parts as I found them to be very installation-specific, i.e. one has to custom fit them one by one. I hope some of the builders may find this useful since virtually no changes to the parts made previously are required. However, I have had no way to field-test this modification and until I do I will not consider the job completed.

Best regards,

Igor Mokrys

Please note my new address: 416 Edgemont Bay, Calgary, Alberta, Canada T3A 2K6

Dear Jim,

Here are my dues and another $5 for the membership list. Who ever died and left you in charge did the right thing.

Several months ago I installed an oil filter on my 0-200, sold by El Reno Aviation (405-262-2387) described in an earlier newsletter. I wanted to eliminate the oil screen and there was a small hope for some oil cooling. The installation was absolutely simple. Bolt it on and you're done. I've never added anything to my plane that didn't require some modification so I couldn't stop here. I built a shroud around the filter cartridge and ducted cooling air to it attempting to increase the oil cooling function. The result was not stunning but acceptable. Oil temp. dropped about 5 degrees down from 220 on a hot day. Next summer I'll try adding some fins to the filter.

I haven't been thinking about oil temp. lately. It's cold now and my oil stabilizes at 180 on a typical flight. The unexpected benefit is the marvelous increase in cabin heat coming through the firewall. My cabin heat box is located six inches below the new filter and admits cowl air into the cabin without use of an exhaust heat muff. Today's blustery 15 kts wind and 30-degree temp. were not big factors as I cruised to Worcester, MA to help a friend with some radio work. When I departed the wind was stronger and colder and I was still comfy!

Best wishes for the holidays and coming year.

Charlie Belshe N469C Q200 (401) 272-3876

Jim,

I now have nearly 90 hours on my Tri-Q200 with extended wings. I am seeing about 160 mph (TAS) @ 2500 rpm and 2500 feet and 190 mph (TAS) @ 2850 rpm and 2500 feet.

I have installed the El Reno oil filter adapter on my 0-200 and it seems to work OK. It is not a full flow oil filter. It only filters that oil that is going thru the left side of the engine, but this has to be better than no filtering at all.

I have solved part of my excessive CHT readings. It seems that when the battery is low and there is a high load on the alternator, (i.e. after starting the engine and on the takeoff roll) that there is enough electromagnetic interference to cause one of the CHT gauges to read high. I can lose 100 degrees by taking the alternator off line.

I have noticed that my cowling appears to bulge at the top between fasteners during cruise indicating the possibility that the cooling outlet is not big enough. I plan to plumb a manometer into the engine compartment to measure the differential pressure of the cooling air across the cylinders. Does anybody have figures on what the pressure drop should be?

I have instrumented all 4 cylinders with CHT and EGT gauges. I can see definite trends in mixture distribution depending on throttle settings. Typically I will see 2 cylinders rich and 2 cylinders lean depending on the throttle setting. As full throttle is approached the lean cylinders become rich and the rich cylinders become lean. In extreme circumstances the difference in CHT can be almost 50 degrees and EGT almost 200 degrees. Very small changes in throttle position can affect these temperatures. Is anybody else experiencing this type of carburetion/induction problem?

David Fulper, P O Box 8751, University, MS 38677

Dear Jim,

This is the letter I promised last month. Tri-Q 200 87TQ has almost 200 hrs over the past 2.5 years. I don't really have too much to say. Problems that I have had during the last year deal mainly with the engine accessories. I upgraded the header tank to engine fuel line, installing a screw in fuel outlet/screen and 3/8" fuel line. Both should have been original installation if you can do it. I also have had fuel weeping from the main tank onto the fuselage underside. Patch jobs don't seem to work. I tried slosh and seal yesterday and am hopeful.

I have another vote to get rid of the capillary oil pressure gauge. Mine didn't get shoved back into the firewall after engine work and chafed part way through during a 1.5 hr. flight. I went through 4 qts. of oil and didn't know it. I am changing to electric.

The last problem I've had is cracking two spinners. I plan to attach the bad spinner to the prop, cut the point off to access the inside and fiberglass a front bulkhead, then mount one good one.

It is still fun to fly and fun to show. If anyone wants to see it, look me up.

Dennis Rose, Aromas (near Watsonville), CA

Dear Jim,

This is a hard letter for me to write and I have been putting it off too long. I have parted out my Tri-Q and sold most of the pieces. I will not be renewing my subscription. This is the bad news.

The easy part of this is to thank you for many fine issues and your devotion to our projects. I, like so many of the other QBAers, looked forward to each issue and read through them in one sitting.

I made several friends throughout all of this too. Never did I ever receive any negative response when calling another member for help. I found them to be selfless and eager to help.

I had two problems with the Tri-Q. The first was over-heating with the Revmaster engine. I suspect that was really due to poor baffling because when I switched to the Continental with its simple baffling, there was never a problem. The second was the reflexor. I still am afraid for those Q-2 pilots who are not aeronautical engineers who will use this and not understand exactly what it does to the lift on the wing. (It spoils lift!)

Is the Quickie still the prettiest thing flying? I believe it is. I am not getting out of the home building business, however, and have started an RV 6. I need to carry more weight and this design will fit my requirements very well.

Jim. Thanks again for all of the assistance. One day, Lord willing, I will see you at Oshkosh. I wish you all safe flying!

Dear Jim,

In Q-TALK #24 Larry Koutz told about his first flight and there is an item that I could probably help him on. He said that he has large nose down forces and he has to compensate with 2" of reflexor. This is exactly the same problem that I had and Scott Swing set me straight. See previous Q-TALKS. Your problem, Larry, is that you don't have enough angle of incidence between the canard and the wing. The canard is in a descending attitude relative to the wing. You need to either raise the nose of the canard, or lower the nose of the wing. In my case, I felt that raising the canard would probably be easier. Don't despair! It only took me a week from making the first cut, to apply the finish paint. You need to cut a wedge out of the fuselage and firewall, leaving the rear attachment intact, clamp the raw edges of the firewall together, and reglass with BID tapes. You probably don't have to completely disconnect the engine from the aircraft (I didn't), just pull it forward as far as your throttle cable will allow.

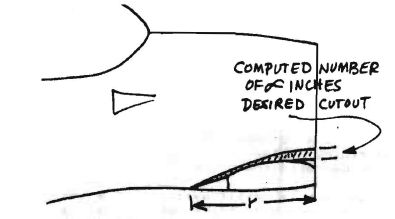

The next question is "how much to raise the canard?" My answer is "I really don't know". However, my guess is that you should probably raise it 2 degrees. (See the many old Q-TALK issues regarding angle of incidence, no need to rehash it here). Now you need to know how much of the firewall to cut out to make a degree. First, measure the distance from the firewall to the aft portion of the canard, this is the radius we'll call r. Now multiply r times the appropriate number in the table. (I used the formula: ten degrees=opposite/adjacent for you engineering types.) This will give you the number of inches of firewall cutout needed to the job.

For example, say you determined your radius to be 18" and you wanted to raise the canard 1.5 degrees. Multiple 18 x .02618. This equals 0.471", just about half an inch.

Degrees Wanted | Radius | Multiplier |

| 1.0 | r | .01745 |

| 1.5 | r | .02618 |

| 2.0 | r | .03492 |

| 2.5 | r | .04366 |

| 3.0 | r | .05240 |

| 3.5 | r | .06116 |

I made this adjustment when I had about 5 hours on my Q-200. Now I've got almost 500 hrs. It flies better, stalls are docile, and it flares predictable on landing. Like all builders, I took what I felt were great pains to make sure that my angles were perfect, but either I made a mistake or the QAC plans didn't properly address this issue. (Remember, the QAC Q-200 did not use the same carbon fiber spar that we use, they did a hand layup! I saw it at OSH.) Maybe this angle of incidence should not be set at zero in the first place, rather up a couple of degrees. I'd be happy to help anyone with this "adjustment" my phone is (618) 549-3302.

Second item, regarding engine cooling, don't forget to put baffles on the cylinder heads not just the cylinder barrels, as supplied with the kit. Happy flying.

Sam Hoskins

You can order a PDF or printed copy of Q-talk #25 by using the Q-talk Back Issue Order Page.