Q-talk 21 - LETTERS - Q-TIPS

- Details

- Category: Q-Talk Articles

- Published: Monday, 30 April 1990 07:11

- Written by Jim Masal

- Hits: 3662

Dear Jim,

I'm disappointed that I was unable to attend the gathering in Springfield, and it doesn't look good for Oshkosh. I will make all of the local events and plan to go to the Kerrville TX fly-in in October. Next year I promise to make it to our Q-bird gathering in Missouri, if I get more than 30 days notice, it's a long day there and a long day back from CA.

I still fly my Q-200 almost every day and am approaching 300 hrs. A couple of months ago I bumped the compression a little and picked up about 7-8 mph, now the 160 hp Long Eze I fly with has to really grunt to keep up, if we stay at medium cruise altitudes. I am taking a trip to Nebraska the first week in June and if all goes well I plan to enter the CAFE 400 the third week of June, just to find out how a stock Q-200 will fare. The 120 mile race at Jackpot, Nevada is another event I am looking forward to.

In the last Quicktalk I read in another letter that my airplane was for sale, I may be able to be talked out of it, but it would take a lot of talking. The Q-200 is just too much fun to part with. It always gets more than its share of attention at different airports, goes faster than most think it could, is very comfortable, can cover a lot of ground in short order. But most of all it has the finest flying qualities of any sport plane, not dedicated to aerobatics, I have flown. Which includes the 235 Lancair, Dragonfly, Long Eze, Very Eze, Glassair I, KR 2. I have a Long Eze nearing flying status but only time will tell which one I like best and which one will go to finance the next project.

You all have fun this summer and I'll see you at the airport.

Barry W. Weber (415) 447-4524

Dear Jim,

I have been letting this issue of Tri-Q bother me for a long time. There are ones of us that still feel function follows form. That is the aft fuselage was curved down for a reason. What I have to say here, please don't take it the wrong way. I admire, respect and trust fully Scott Swing conversion and if it wasn't for his efforts many of our insects wouldn't be in the air at all. Tri-Q is inevitability the sure fire way for those pilots that feel uncomfortable in a true taildragger to get their projects into the air safely. This means I truly respect anyone who admits that tail wheel is not for them. If one who loves the looks of the Q-2 and is contemplating the change, consider this. Same-O-Same-O. Unless you are willing to undergo an extensive training program or already have at least 40 hours of tail wheel time, go ahead and guild the unorthodox looking bird, please park them together on the ramp. Your drooping tails look funny setting beside the sleek taildraggers of which the original design was supposed to be. I won't mention the weight difference because I have yet to see it printed or I missed it. Now that I have ticked every Tri person off, I would like to add that I'm only joking a little. I love to see any Q setting on any ramp at any time or any place, OK? I'll admit I was probably the biggest chicken when it came time for me to learn how to fly the taildraggers during my completion stages. I might ground loop tomorrow and some of you reading this might wish I would. I already have joined the club and it just makes you a better driver the next time you strap one of these tigers on. I still have problems landing, 7 degrees/reflexor/toe-out/aileron steering and my total undivided attention every single time I meet the runway. My total time is 225 hours on my Q-2 Revmaster. I hope I can continue flying with some success. Jim, a great newsletter. The information is without a doubt, TOP NOTCH. Thanks for all of your condoling efforts for our projects. Without you, we would be nothing I promise you.

"FLY A TAILDRAGGER"

Don Short, Stillwater, OK

Dear Jim, 5-9-90

Hay Mon, I was at Sun 'N Fun Friday, Saturday, Thursday and Sunday, but was not mentioned in the May QBA. I'm hurt, not to mention I didn't get my picture in with the rest of the bunch. Really, it was a good showing for the Q bunch. I'm throwing a 5th year birthday party in July for my little Q-200 bird. She has 82,000 miles on her, 3.4 times around the world, 2400 gallons of gas has gone down her carb! On my third set of tires. Still looks almost new and ready for lots more years. Only broke the tail three times (my fault), one compound fracture, two cracks - minor. Cracked an exhaust valve boss and had to get cylinder welded. Broke the starter 4 times and had high altitude misfire twice before finding a carbon track in a magneto. I've been to 14,000 feet, landed in and took off in the rain (scary, don't recommend), flown through torrential rain, been blown off the side of mountain in Tenn., thank God for 100 HP, I powered my way out of trouble. Lesser planes would definitely have crashed. Had one electrical failure and landed without a radio. Had radio quit twice after being frozen in New Jersey in December, can you blame it? Most of the stuff happened in the first three months, then just the standard airplane stuff.

May 30 we start the Bahamas season again with a trip to Eleuthera, we land at Rock Sound and stay at Edwina's Place. It is 457 (thank the Loran) miles away from St. Pete, FL. We play on some of the most beautiful, totally deserted beaches in the world, eat Conch chowder, lobster and coconuts and snorkel the reefs surrounding the island. One night we drove out into an unpopular area and shut the car lights off. After a few minutes the stars on the horizon were as bright as straight overhead. I'd never seen anything like that before, it was awesome. The natives are extremely friendly, there is no crime, and it seems like another world, though primitive. I am totally in love with the Bahamas, Freeport is OK, Nassau stinks, and the out islands are great. Only tell QBAers because too many people will spoil what I like.

On Thursday at Sun 'N Fun, I was parked next to a Dragonfly with two customs (Thank You DEA) stickers (meaning it has been over the ocean two different years) and I'm going to get my third this year (they cost 25 bucks, I better show 'em off). We're planning 5 Bahamas trips this year and maybe one to Kill Devil Hills, NC to visit the site of the first powered canard airplane to fly (why do so many airplanes have the tails on the wrong end?).

In reference to the May Q-Talk #20. One builder asked about using the supplied clear tubing for crankcase ventilation, don't be crazy, the stuff gets soft as wax when hot, use 5/8" auto water hose at least. I used the clear tubing as a funnel for putting cold oil into the oil sump, it's a real tight fit and you can't get a quart bottle through that little hole in the cowling. A question was asked on glide speed. Each airplane has its own best numbers and the builder should determine the numbers during his 25 or 40-hour test period. I found my standard Q-200 to stall at 70 MPH, Vx=85, Vy=120, calculated Va=140 MPH, tested Vmax=225 MPH by flutter testing. My best glide speed is 120 MPH found by having 700 Fpm descent = 15:1 glide ratio. My airspeed indicator can be corrected by the following formula IAS*.89+7.7=TAS and when I'm right on the deck at 180 MPH at sea level I read 200' altitude due to ground effect. If I land, the altimeter reads 7 feet like it should. My compass is calibrated to 3 degrees, my oil temp is accurate to 1 degree, my VOR is dead on, ...everything can be tested and adjusted.

LORAN-C OPERATION - I am an electrical engineer and have a successful Loran installation. Questions come up in Q-Talk from time to time on installation of Lorans. There are two principles involved with operation of Lorans, 1) Signal, 2) Noise. If you have a lot of signal you're in good shape, but guess what... if you have a lot of noise you're in trouble. The signal comes from two places, the antenna, and the GROUND. I highlighted the ground because it is the most misunderstood, and important, part of a Loran installation and the toughest part in a Q-plane. I can't go into great detail here but what you have to do is connect all the metal in your airplane to a common point, preferably the battery negative, or the large battery cable (-) where it meets the firewall. The Loran is then also connected to this GROUND. The noise side of the problem occurs from the alternator, transponder, strobes, or comm transmitter. Use a heavy shielded wire from the alternator straight to the battery. Ground the shield only at one end, and install a commercial alternator filter or a 10,000 microfarad 50 volt capacitor right at the alternator power output terminal. You could use the new linear regulator I saw at Sun 'N Fun if you really have problems. Modern regulators put out tons of noise. Other items that cause noise are the transponders. I had to move my Narco AT 150 transponder to behind my right shoulder in the baggage area to eliminate the noise it put out. I'll bet that the solid state Terra Transponder is noiseless, but don't know... Try measuring the noise with the engine shut off, then start the engine, and measure the noise again, then turn the alternator on and measure the noise again...do this with all the electronics until you isolate the noise, then fix it!

Mike Dwyer, #2841, (813) 595-2382, Seminole, FL

Dear QB,

Excitement is building as I begin construction of Quickie #280. Templates ready, workbench built, hotwire and epoxy pump ready. I need help from someone out there with a problem I'm having locating some sheets of Rigid PVC 8mm thick 24"x60", 3.4 lb density, type 55. I have not found anyone who carries this stuff and haven't found consistent answers as to a suitable substitute. I talked to a representative of Clark Foam who said they could make me up some 8mm closed cell polyurethane 3.75 lb density, but would not commit to an answer as to whether this would be a suitable substitute. I would appreciate hearing from anyone with a solution to my dilemma.

Bill Archer, 290 Columbia 36, Magnolia, AR 71753 (501) 234-7983

Dear Jim,

Here's our twenny beans for another year's dues. Sorry I'm late with this report but I have excuses that range from A) The dog ate my homework to Z) The snowplow ran over my books.

My partner (Larry Weishaar) is frantically building an N3 Pup ultralight. Damn thing is made out of rags and metal tube! I think the guy has gone over the edge. Builder support has been great unlike some we know.

I find the testing guidelines you composed to be very good.

A couple things we experienced might be of help.

Care should be taken in any full or near full throttle run-ups with the brakes locked. In the tailwheel configuration, our plane's tail had a tendency to come up. I don't know if it would come up enough to get the prop, but it was an uncomfortable feeling. Someone should hold or tie the tail down.

In the Tri-Q, make sure the nose wheel dampener is tightened to specs or tighter. I set ours about 15 lbs, but ours doesn't have the proper amount of trail in the nosewheel fork pivot, and the shimmy can be very violent if it is not tight.

Ten gallons of fuel should be adequate for first flight. We added enough ballast in the baggage compartment to bring the CG near the rear of the envelope.

With light fuel and no ballast, we need about 2-3 degrees of aileron reflex for a comfortable climb out. With no reflex it requires nearly all the elevators to haul it off at 85 mph. (This might be due to the STOL tips we added to the main wing.) With heavier loading, less reflex is used. The reflexor works just dandy.

We highly recommend the three wheel conversion - it REALLY turns it into a baby buggy on the ground. We have a decidedly heavy left wing and too much propeller and are addressing those problems with all deliberate speed. We've already increased the "bite" of the sparrow strainers and will put in a little differential elevator to bring the roll control into the capabilities of our electric roll trim.

The reverse flow cooling on our C-85 works almost too well. One of our fixes is to cut down on the warm air exhaust area by 30%.

OUR LATEST SPECS:

Empty weight 695 lbs (little sucker must be sneakin' chocolate chip cookies!)

Left main gear 240 lbs

Right main gear 245 lbs

Nose gear 210 lbs

We are using a C-85 with an Ellison injector. Can't say enough good about the support and service we have received from Ellison. We use a B&C alternator which performs well.

We are getting 160 mph cruise at 22 inch manifold pressure and 178 mph is as fast as the 85 ponies will pull.

It stalls or mushes at about 80 mph with just one aboard. With enough ballast, I can induce the pitch-buck and in a power on stall, the pitch accelerations are rapid enough to get your undivided attention.

As a taildragger, the airplane took one unscheduled trip through the boonies (don't they all!), and kinked one of the axles. At one G, the tube called out in the plans is stressed to more than 50,000 psi, which is chancy for 6061 aluminum. We changed to 5/8 x /.120 4130 steel which brought the stress down to less than 30,000 and would be good for about 2.5 G's (disregarding the strength contributed by the heavy-wall spacers to position the wheels in the pants). The change adds about 5 oz per axle.

I (Doyle) just returned from the first long cross country from Springfield, IL to Manhattan, KS - 820 miles round trip in 5.5 hours and used 25 gal. of fuel total. That's probably no record but I am quite satisfied and it sure is a good feeling when you fly into a strange airport and draw a crowd of potential new friends!

Jim Doyle/Larry Weishaar, Springfield, IL

Dear Jim:

Random comments on Q-200, N-200DN as follows:

1. The brake modification where you build a frame floating the calipers on 3/8" bolts and then mount the frame inside the wheel pants works great. I no longer need 3,500 feet to get the aircraft stopped.

2. I also installed a second master cylinder and have differential brakes. I mounted a second handle also on the left console, connected the two levers at the top with a bolt that will swivel much like the trim bolt on top of the elevator levers. I also attached a turnbarrel on one of the cables going to the master cylinder so I can keep the two pull handles close together. I consider it a big improvement both taxi and landing. It was not as sensitive as I had expected after hearing other reports.

3. Dragonfly tail spring works great. Throw away the Quickie one. It don't fit the hardware anyway.

4. Fat tailwheel and self-centering tailwheel springs are big improvement. Note: I made a 17# tailwheel assembly for weight and balance purposes.

5. I sawed a large hole thru the top left side of the main tank on a 45 degree bevel to check the glass inside. After 3 years of mogas the glass was hard and clean. The bare 1/4x1/4" white foam strips used to hold the flox squeeze out while mounting the tank are breaking up and being caught in my see thru filter going to the header tank. I also remounted the fuel drain in the left rear corner of the tank which will be lowest point as it sits on my trailer parked in my garage.

6. TAS 185 MPH full throttle, 160 @ 2,500 RPM. Still have a left roll and a 5 degree down left elevator at cruise. I have not been able to solve the problem. The Bob McFarland mod - adjustable turnbuckle on the left elevator p/p rod does not help much. Tweaking up the trailing edge of right wing didn't help much either. The aero-engr's in my office say yaw is the biggest culprit to trim problems. Maybe my vertical fin is not on straight. There was no scientific manner of mount it! Perhaps adding 3/4 degree nose up on canard would help. Right now I don't think I will do it. Too much work for maybe no help. Welcome any ideas.

7. The Tony Bengalis air scoop under the engine case blowing onto the oil tank reduced the oil temp from 215 to 190.

8. I note where some folks are using 1200# as max gross weight. Where do they get that figure? I have pitch-bucked mine at 1200 gross weight and the only difference was the pitch-buck was at 80 MPH rather than 65 when I'm solo. Approach speed was adjusted to 95 @ 1200# GW.

9. Final personal comment - Sure wish I could paint. I don't have $1,000 for the painter so the aircraft looks rough. I note where most builders hire that done.

Regards;

Dave Naumann, 410 Lakewood Dr., Enterprise, AL 36330

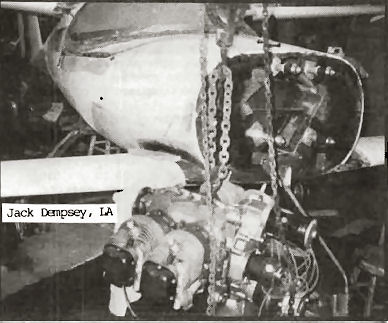

Dick Pratt is now testing his Q-200 with this nifty swing-away engine mount.

WE FINALLY DID IT! Got all of the bugs worked out of our Onan. Cylinder head and oil temperatures under control, starts on the first blade, around fifty hours of trouble free flight, time to really USE the little beauty. After spending a couple of uneventful hours buzzing around the home field, Ves, my partner in the Quickie, decided to fly over and take a look at the mountains. Around 50 miles to the west he looked down on the largely unused Winston-Salem municipal airport and decided that the call of nature would provide a perfect excuse to indulge in the luxury of a choice of long, wide runways. Approach control cleared him in, but quite a ways out offered him the option to change to another runway more aligned into the wind. Being your experienced Quickie driver, he wisely elected to accept the gift. After 30 seconds or so into the go-around, the Onan decided to once again bite us in the tail feathers. A sudden, drastic loss of power, accompanied by big time vibration caused a short, high-pitched discussion with the good people in the tower, and a return to the original approach. As it turned out, the approach was normal and the landing uneventful with one small exception. I must digress: a landing at our home field, without power, causes only a few caustic comments. "Oh, I see you are dragging the Quickie in by the tail, another power failure?" "No you SOB, I'm checking the weight and balance by weighing the tail!" But at a controlled field, such a simple occurrence causes bells, whistles, fire trucks, ambulances, rescue vehicles, airport managers, local press, tow trucks and the friendly folks from the FAA.

The Onan stopped making airplane sounds at touchdown. Ves was able to coast to a position very near the first turn-off and had gotten out and picked up the tail in the usual manner to move the Quickie off the active runway. It appears that one doesn't just pick up one's aircraft at a large municipal airport. Ves found himself inundated with assistance. In the first place, because no one had every picked up their airplane before, it was decreed to be unacceptable. The tail of the disabled aircraft must be placed on the official tow vehicle. However, the height of the official tow vehicle precluded the accomplishment of the officially decreed procedure. After a prescribed period of time, while the firemen were sweating profusely within their aluminum suits and the ambulance attendants got tired of playing with their radios, it was determined that if Ves sat in the trunk of the Airport Manager's Official Car with the tail of the Quickie in his lap, the operation could then be construed as an official "tow". The evolution was conducted in a general tone of levity with the possible exception of the friendly person from the FAA. He concluded that because no emergency was declared and no damage was done to persons or property, he had no function in the matter. He reluctantly discarded his voluminous notes, although he did announce that he had expended at least two crayons (green) at government expense.

A quick inspection revealed the following rather frightening condition. We were using spark plug caps that feature a spring wire that engages the threads at the top of the spark plug. The normal Onan vibration had worn the top of the plug as smooth as a baby's butt. The cap had simply slipped off. The other side was nearly as bad. New plugs and caps locally obtained solved the problem. The take-off was accomplished with the cheers of all officialdom involved (with the possible exception of one poor crayon counter). We have since secured the spark plug caps in place with tie wraps. Think about this during your next pre-flight.

God divided up His world, the ground He gave to man and squirrel,

The air He gave to beasts of flight; simple creatures, dumb but light.

God gave man fingers, instead of wings, so he could build expensive things.

And so we clatter through the sky, the chosen few, like you and I.

And when our mechanisms fail, we simply sit there still and pale.

We wonder why we left His land, and trifled with His master plan.

But if we try, and prove our worth, we safely land on Mother Earth.

We soon forget the fear and pain, and fix the Onan once again.

But when the final message comes, and a propless Onan hums,

Since I am a mortal man, with soundless glider in my hand,

I say, "Oh Lord, just one more round to get this bastard on the ground.

And if I do, I swear to You the cycles will go down to two."

THE LORD WAS BENEVOLENT

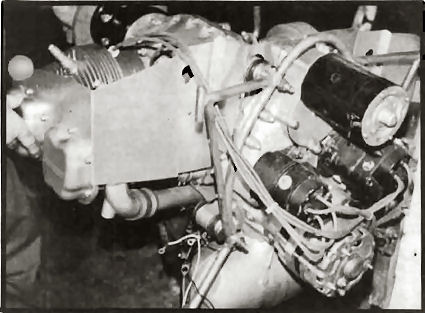

HEREIN BEGINS THE ROTEX STORY

As you probably gathered from the above sonnet, we lost the prop in flight. I had tried to remove the prop hub for painting. A few light taps with a small hammer were followed by a few heavy taps with a light hammer then a few light taps with a heavy hammer and so on...

We finally made a steel fixture so that we wouldn't bend the hub any more than it was and then BROKE a gear puller trying to remove the hub from the engine shaft. It is amazing what a few molecules of rust can do.

When we finally got the hub off we sent it to a machine shop to have the flange trued up to the rotational axis and a light scratch turned inside to remove the rust. Upon reinstallation there was a very slight looseness in the fit that was easily corrected by snugging down the bolts holding the assembly to the engine shaft. There was no noticeable improvement in anything at all but at least we were back in the sky. After a few pleasurable hours in the air, Ves was buzzing around the countryside at 2,500 feet a few miles from the field and reported hearing a loud "snap" followed instantly by a "bump" and then the Onan ran more smoothly than ever before. Unfortunately it was running around 6,000 rpm. To this day Ves swears that he didn't realize that the prop was gone. In fact, in his standard emergency transmission to the field he reported a "disconnect" between the engine and propeller. He made his usual proficient dead stick landing and only then did he observe that the cowling was pretty much destroyed. I have always imagined, and assumed that if a propeller came loose it would "screw" itself off into infinity. Not so. As soon as a propeller becomes detached it looses its rotational inclination and suddenly slows down so you fly into it. In our case we were fortunate that it impacted the cowl and not the canopy or other critical surface.

I must admit that I have been fighting Ves on the idea of going the 2-cycle route. I cite the "reported" unreliability of the outboard motor power plant. Ves, in turn pointed out that the reliability of the Onan, in our case, was nothing to write home about. I am now convinced. (Don't tell Ves this but I was convinced last year at the QBA wine and cheese party). After a long, wine soaked conversation with Jinx Hawks, I think it was Jinx (I said it was wine soaked) I became a reluctant believer.

We will keep you informed on our progress. So far all traces of Onan contamination have been removed. The firewall has been reglassed, and the motor mount is completed. That's another story, good old product liability again, try to find a welder that's good enough to fly behind but is dumb enough to believe that the mount he is working on is for a wall fan. We did and I think he did.

More of the Never-ending Story later.

Harry L. Buskey, Rt #1, Box 289I, Liberty, NC 27298

(919) 622-4022

Dear Jim:

I start an orthopedic surgery residency and will be in Houston for the next 5 years. I am now a civilian.

My Quickie is again flying after a 3 YEAR grounding (not able to take it with me when I was a Navy flight surgeon). My first engine lasted 220 hours and I decided to stop hassling with the studs pulling out as a result of poor engine cooling during the first 100 hrs. I bought a "new" Onan from an incomplete project and I will use the good cooling arrangement I finally worked out and previously described in QUICKTALK.

This new engine was not an easy retrofit because it was one of the first sold and had an oil filter and a 1.5" shorter prop shaft than my original. I ended up having a machine shop make a longer prop shaft. I also removed all the flashing from intake and exhaust valve ports and cylinder heads. I installed the 20 hp heads.

The engine runs fine and performance is similar to the original engine though it seems to vibrate a bit more. My tach is on the fritz so I am not sure how it is turning up. Top speed is about 122 which is consistent with 3700 rpm on the old engine.

I also replaced the center elevator hinge bushing because of severe wear and slop in the hinge. Now the elevator is within tolerance. I also noted some rust, actually quite a bit, on the old prop shaft and extension. This was hidden due to the installation with the center bolt and keyway. I like the older method (perpendicular bolts through the shaft) because it leaves the shaft visible for inspection when the prop is removed.

I will be bringing my plane to Texas and I do plan to go for the straight line record of 777 miles by Norm Howell now that an Austrian broke my closed course distance record.

Steve Eckrich, Houston, TX

Dear Jim,

Alternate powerplant info for the Quickie is always of much interest in Q-TALK (still don't like two-cycle, but will most likely use it). The extra four pages in Q-TALK 20 on Sun 'N Fun was terrific -- instead of slogging thru tasks, I actually felt the old "Wow, this thing's gonna fly" feeling...so, whatever you do, hang in there. You'll get to take credit for a lot of us getting airborne over the period of your editorship of Q-TALK.

D. J. Harms, Newton, KS

Dear Jim,

I am building Quickie #523. I started several years ago and ran out of space and time. I now am home and can afford more time. The fuselage and wing are done and have just flipped the canard over to glass the top. I would like to get up to date on the newsletters. As you might expect I'm not too wild about the brakes on the canard. They look pretty lame. Now is the time to find out if there is an alternative. And maybe I could pick up some good points from other builders.

Jim Stovall, Summerville, SC

Dear Jim,

I just read in Sport Aviation that you are having a QBA dinner at Oshkosh on Sunday, July 29th. Please put our names in the pot. My wife and I plan on arriving at Oshkosh on Tuesday the 23rd. This will be our first trip and we are really looking forward to it. Quickie 7NH is languishing in the shop awaiting my attention, moving to the Denver area has taken nearly all my time including building a new shop to plan in.

Howard Hardy, Broomfield, CO

A minor note: We have a wine and cheese party at the University, not a dinner as many of the type clubs do. With these little airplanes, we can't afford to be big eaters. - ED.

Q2-2015 update, Jan 1/90, Bob Falkiner, C-GJWH:

I have about 4 hours taxi testing, starting with low speed and working up slowly in 50 rpm increments to tail wheel liftoff speed. Several comments:

I think anyone who flies a Q2 without differential brakes is out of his/her mind - absolutely NUTS - completely around the twist. I can't imagine relying on "aileron" and rudder steering!! No wonder that the Tri-Q is so popular! I installed C150 dual pedals and brakes because the person doing the test flying insisted. Have to thank him for that some day. I left a lot of rubber here and there, and would have been in the cornfield more than once without them. I know of 4 Q2's in the area. All have differential brakes, and none have been involved in serious accidents.

I have about 15 degrees of positive caster, as opposed to about the same amount of negative caster in stock configuration. There is no tendency for the tailwheel to lock up in a left or right turn, and it will self center with feet off the pedals.

I got a sneaky case of vapor lock. At about 75 deg OAT, it showed up after several high-speed taxi runs as a loss of RPM on the takeoff roll. The first time, I thought that I had just shoved the throttle in too fast, as it hit max RPM then sagged and recovered. In later runs, I noticed that the RPM was sometimes not reaching 3100 all the time, sometimes with little sag or RPM fluctuations. If I hadn't been looking, I don't think I would have noticed and would have taken off with less than full power. John Wirta had a real nasty case this summer - almost idle to full RPM surges during hot weather taxi. Both of us have gascolators mounted low. Mine is purposely at the same height as the RevFlo carb to minimize vapor lock. Mounting it lower will aggravate it, as the carburetor may start to "suck" the gas (negative pressure at the carb inlet). I intend to insulate the lines, and put a blast tube & air deflector. QAC recommended this in one of their newsletters. If you are having unusual engine operation, such as RPM fluctuations, slow throttle response, hot lean problems, or drop in max static RPM as the engine heats up, check it out. I have purchased a couple of Radio Shack thermometers and will log fuel line temperatures for the record before I insulate.

You can make a nice stainless exhaust for a Q2 out of stock Aircraft Spruce and Specialty parts - two 180 degree bends and 4 90's. John Wirta did his first. I liked it, and put one on mine after I cracked one of the stock pipes trying to make everything meet at the collector. It only took 1 1/2 days to do the pipes and the baffling. I was working in a shop, and one of the guys was fairly handy with a torch (yes Virginia, you CAN weld stainless with a Dillon). I designed my panel to be removable, but after all the wires were hooked up, it might as well have been welded in place. I re-wired to use two 12-pin mate-n-lock (computer & automotive) for the electrics and lights, and one 25 pin RS-232 for the gauges (quad EGT/CHT, volt/amp, temp/press = a lot of wires). All the gauges go to a 24 pin terminal block on the firewall, so that senders can be changed without touching the cabin wiring. The mags connect to the panel with 3 BNC connectors. I can now remove my panel in about 3 minutes for maintenance.

When I first fired her up, I wiped out Unicom frequency with ignition noise, and I think every a/c within about a hundred miles could hear me. Silly me. I have a 1/2" aluminum 'U' channel ground buss that doubles as a panel reinforcement that goes the width of the panel. I grounded the mags close to the mag switch, near the center of the ground buss. The Revmaster Bendix mags do not have condenser filters on the 'P' leads, so what I inadvertently built was essentially a 1/4 wave horizontally polarized dipole antenna tuned almost exactly to Unicom frequency!!!!! I did not know that 'P' leads should be taken back separately to the principal ground point on the a/c to the mag case itself. Also, the metal casing of the standard L-R-B-Start ignition switch is NOT connected to the GND lug on the back of the switch. The case is grounded via the chassis if mounted in a metal panel. In a wood or composite panel, the switch would not be properly grounded unless you run a separate wire from the case to ground. I've fixed both, and will report when the ice is off the rivers up here.

Mundane problem with canopy leaking water & snow - drips on the gauge (damn!). The last time I

SEE YOU AT OSHKOSH '90 (!!!!!!!!!)

Dear Jim,

My project, #2784, is still active but I may be the champion in long time construction. (ED. NOTE: Not yet you ain't... It won't be easy to establish that record.) I started in February 1981 and here I am 9 years later. But, by God, I will finish it if it's the last thing I ever do... and it may be!

My controls are full of mods since I couldn't get much to fit right from the plans. This leads me to a builders tip. When I drilled the holes for the thru - bolts on the controls - elevator and aileron tubes - I really did the best I could but had great difficulty getting them right. I ended up with some pretty sloppy joints. What I needed to do was re-drill the holes oversize and get an oversize bolt, which would have to be tapped through with a small hammer. But where to find such a bolt...and each joint was different!

I made my own custom bolts. I took a long AN-4 bolt and chucked it tight in my drill press (head down). Then with a file (first coarse, then smooth) I "worked" the bolts down to size like on a lathe. You can get incredible accuracy doing this - half a thousandth, easy. Just check diameter often with your vernier caliper as you're turning (filing) down the bolt. Since you've previously redrilled through your joints with the smallest oversize drill you can get away with (the largest outside hole diameter), you know rather exactly what the bolt diameter should be. Stop a thousandth or so above this on your bolt diameter then cut off the larger bolt end and check how tight it is in the holes. If OK, put it back in the drill press (this time, head in the chuck since you've cut off the other end... my 1/2" chuck will easily take AN4 or AN5 bolt heads) and "polish" off what you need. I aim for a "tight" fit. It should have to be pushed in hard or tapped in with a small hammer. The result is a joint with no (that is, zero) play. When satisfied with this, all you have to do is cut threads on the 1/2" or so that sticks out beyond your joint. Don't thread too far...just up to the outside surface. Use your 10-32 die for AN-3 bolts.

Each joint rebuild takes about an hour or two to do. Of course, there is a down side to all this: AN bolts are cad-plated for corrosion resistance and this disappears right off the bolt shank. Hope you keep your Q-2's hangared!

I was heartened by your comments on the "not for show" results some builders get. I've been to Oshkosh and seen those beautiful planes - mine will not look like them. I just don't have the time - talent - money it takes for those results. But I do intend to fly my Q-200 and expect it to be safe. I've not cut any corners on anything regarding structure, safety, etc; it's just that it may look - well - "homebuilt" when it's done. But I'll fly it to Oshkosh someday and park it with all the others. Perhaps someone will take heart that they too can build such an airplane.

Jim Schenck, El Paso, TX

About that last sentence, "Three cheers for you!" Now who else will jump in on this trend? - ED.

Dear Jim,

I haven't belonged to your association for some time. I gave away my Q2 a couple of years ago. The fellow I gave it to got divorced, has no house, etc., so I have a Q2 back. If you or any friend would like to have the Q2 complete with engine please give me a call. It's about 2/3rds done. It's for free, I just don't have room at this time to store it.

George Koeneke, Strathmore, CA (209) 568-1506

Dear Jim,

First of all, let me advise all Quickie drivers that their aircraft are just as susceptible to wind shear as any other plane. Imagine that you depart the field one crystal clear morning for a jaunt over the coast. The air is just as smooth as glass. As you get closer to the shore and proceed up the coastline, the turbulence becomes just plain nasty. You decide to drop into the Halfmoon Bay Airport and make a fishing reservation; Salmon reason, you know. You're on final approach about 600 feet above the yacht harbor. The plane is really getting bounced around, so you deliberately hold your airspeed about 10 mph higher to give yourself some leeway. A bad one hits (rotors boiling down from the hills). The entire right side of the plane stalls. In the blink of an eye you are 45 degrees nose down, 70 degrees right bank and in a spiral. That yacht harbor is growing bigger in a hurry! Recovery is conventional, about 300 feet altitude lost, and you come out of it pointed the opposite way. You figure "someone is trying to tell me something" and skedaddle out of there. As soon as you cross back over the hills into the valley, it's just as smooth as glass!

Robert Godbe, Palo Alto, CA

GEEz, you shoulda had a V8. - ED.

You can order a PDF or printed copy of Q-talk #21 by using the Q-talk Back Issue Order Page.