QuickTalk 8 - FLYING REPORT

- Details

- Category: Q-Talk Articles

- Published: Monday, 28 February 1983 06:11

- Written by Duane Swing, Vandalia, OH

- Hits: 2271

I have been encouraged to write this letter in response to the numerous phone calls and letters received after our Q2 was displayed at Oshkosh and pictured in various homebuilt aircraft publications.

I feel from this response that most of you have the technical problems resolved and it would be redundant for me to discuss them in this letter. I do, however, promise to provide assistance to those who elect to utilize the forward sliding canopy which was incorporated in N1711Q.

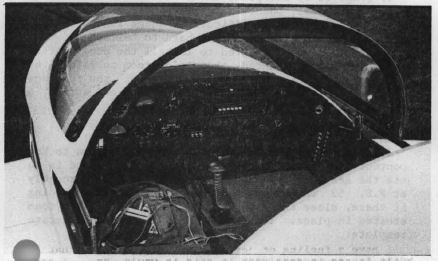

I would, instead, like to discuss first flight preparations, flight testing, cross country and weather flying. N1711Q is unique in that it incorporates the latest state of the art avionics with digital COM, four way-point RNAV, slaved HSI, Century II autopilot coupled to the HSI and a vacuum pump operating the artificial horizon.

My son, Scott, and I have accumulated over 100 hours flying the airplane in just about every kind of weather except icing conditions. I'll try to point out only those areas of flying that I feel are important to the safety of the builders.

FIRST of all, don't rush that first flight. Make doubly sure you have established an empty CG position that will allow a forward-loaded airplane to remain in the CG envelope. Flights outside the forward CG envelope are guaranteed to age you ten years and probably cost you a prop in the process.

SECOND, get some tail dragger time just before you fly your Q2. Scott had a total flying experience of just over 50 hours in a 150 with two hours in a Citabria just before his solo in the Q2 (we do not have the dual controls). He has not had any difficulty in flying the Q2 and has probably put 50 or so hours on the plane to date. We have both flown the plane at about 100 lbs over gross (1100 lbs.) with only minimal reduction in performance.

THIRD, ballast the airplane to a mid-CG envelope position until several hours of flight time is under your belt. Any deviation from the mid-CG location will, more than likely, alter the landing characteristics enough to cause some instinctive reaction correction.

FOURTH, any forward CG will probably result in a landing on the mains with the tail wheel anywhere from inches to a foot above the runway at touchdown. This is a difficult situation to be in due to the full back elevator and the probability of "bounce - pitch up - stall - fall - bounce - pitch up - stall- fall" until flying speed is below about 40 MPH. This problem is much more in evidence if you have picked up some bugs or grass, with the resultant loss of lift of the front wing. (You have, in effect, moved the CG forward). Rain is even worse. If, for any reason, your elevators are not lined up with the tip fillets at cruise speeds, you should reflex the ailerons up about 1/8" (trailing edge) for each 1/2" of elevator below the fillet. This works for whatever CG you happen to have at the time.

This bring me to point FIVE. I would STRONGLY suggest an aileron reflexer to adjust this elevator position in flight. In 711Q, in condition of full aft CG at 1000 lbs., adjusting the reflexer to establish a trail position on the elevators results in a three point landing every time. Conversely, flying at the forward CG in heavy rain with the reflexer again set to give the elevators trail position will produce a three point touchdown. Your speed, however, will be at least 10 to 15 MPH higher than normal. Remember, rain reduces lift on the laminar flow front wing. To compensate, the reflexer reduces lift on the rear wing. The tail mounted trim system sold by Garry LeGare, is probably far superior to the reflexer and will be installed in 711Q time permitting. As it is, the reflexer does help and should be considered a must. Ours is a simple heavy duty throttle vernier from a Bonanza mounted on the vertical seat bulkhead between the two seats and connected directly to the aileron torque tube about 2" in front of the bellcrank. The phenolic bearing blocks were elongated to allow the torque tube to move up and down about 1/2" total (aileron trailing edge has a 1/4" down - 3/4" up allowance). This might be more than most of you will ever need, however, I have had to use the extreme on one occasion of heavy rain.

For those of you who want to venture into the world of IFR, a word of caution. The reflexer, or tail trim, is an absolute must. Even then, flying into and out of visible moisture will keep you very busy with the pitch axis. In addition, the airplane will slow down in rain due to the reduced lift and attitude change needed to hold altitude. This will probably result in higher CH temperatures, which requires opening the cowl flap creating more drag, etc., etc. A far more critical factor, however, is the propeller erosion in rain. Fifteen minutes in light rain, followed by 30 minutes in heavy rain, reduced the airfoil section of the stock propeller by 3/4" at the tip. Trying to keep a grossed out Q2 flying with full power in heavy rain with a prop that is being destroyed by the shotgun effect of rain is guaranteed to give you pucker-induced hemorrhoids. We will be experimenting with a urethane coated leading edge prop made by Warnke in the near future.

Another area of experimentation is the sparrow strainers, as used on the elevators of the Dragonfly. The initial tests produced some surprising results in that the constant down pressure exerted on the elevators reduced the pitch instability that is present on the Q2. This is especially noticeable at higher weights, aft CG and altitudes above 7,000 feet. It was not uncommon in these conditions to require 100% hands on flying to control pitch attitude. At forward CG and lighter weights, the airplane will fly hands off for extended periods of time with only rudder used to control wings level and direction. The elevator mod seems to minimize this adverse condition and may totally eliminate it. In addition, we have removed all counterbalances in the elevators and find the plane handles much nicer. There is also a tendency to land in a more tail down attitude. The reason, however, is unknown to me. For those of you who built your Q2 for cross country flying and are afraid to venture beyond the airport boundary, a word of encouragement. My son, Scott, has made non-stop VFR trips in the 850-mile range at speeds in the 160 MPH area. He has flown in and out of high density airports with and without passenger, with baggage, and at times in light rain. My wife and I, with about 50 lbs. of baggage, completed a 2200-mile trip from Dayton, Ohio to Myrtle Beach, South Carolina, on down to the Cape for a few days before going on to Fort Myers, Florida and back to Dayton. Total flight time was 15 hours, 46 minutes for a block-to-block time of 140 MPH. Fuel consumed was 60 gallons for an average of about 37 miles/gal. About 50% of the flight was IFR at altitudes of six to ten thousand. Much of the VFR flying was done dodging cloud buildups and climbing to 11,500 feet to stay above weather. Our DME was usually showing about 125 to 135 knots. Block speeds of 150 MPH would have been the rule if straight line flying had been possible.

We continue to improve performance (wheel gap seals, almost constant speed props, fairing over exhaust, etc.) and comfort (exhaust cabin heater, aileron trim, elevator sparrow strainers, etc.,) and will give you an update as time progresses.

/Duane Swing, 46 years old, holds single, multi, commercial and instrument ratings as well as an A&P license. He has over 5500 hours and presently flies a 70 CR Twin Comanche in his business as a manufacturer's sales engineer. His son, Scott, 24, was the prime builder of N1711Q. Scott has a private license and is finishing a Master's Degree in Business/Marketing.

N1711Q began as kit #2229 in October 1981, to fly for the first time in mid-May 1982. An estimate of building time was put at 850 hours. Almost all work was done on a time available basis with the exception of a two-week vacation devoted to construction. The paint is DuPont Centauri acrylic enamel with hardener added. Wings were spline sanded back to the primer, repainted, spline sanded to dull along with the entire airplane with a 1200 grit paper, then rubbing compound buffed to a mirror finish and sealed with McQuirs Mirror Glaze. Empty weight is 615 lbs. To date, over ten Q2 builders have had their first ride in 1711Q. A color photo can be seen on page 60 of the January SPORT AVIATION./

You can order a PDF or printed copy of QuickTalk #8 by using the Q-talk Back Issue Order Page.