the firewall to the canard and are attached on the aft side of the firewall on either eide of the pie-pan. Use flox and glass tape to join. Also, the canopy must be well sealed or else the perceived vibration level will increase significantly from the canopy assembly âdrummingâ. We use the MO Foam Tape of size 3/8â thick by 1/2â wide

made by the Macklanburg-Ouncaun company of Oklahoma City, OK. It is available

in most hardware stores and is also self adhesive. We seal all of the way around

the canopy. Finally, experience has shown that the canopy pin detail shown on

page 15â8 will not remain tight if the steps above are not taken. Therefore,

we recommend that instead of using flox for the filler, that âLiquid Steelâ (epoxy

type)can be purchased at a hardware store. This ia a very durable filler. We

squeeze it into the hole, grease up the pin to prevent adherance, and close the

canopy. Letting it set aver night allows the liquid steel to harden.

.....Once you have checked all of the airframe areas

mentioned above, you can turn your attention to the engine mounting system itself.

A vibrating engine can yield very high loads on the engine mounting system. Proper

quality control on the workmanship is essential.

.....Three of the early builders to fly reported

breaking one of the 1/4â engine mount bolts during the first 10 minutes of operation.

Although we have never had any trouble with N77Q and other Quickie builders were

flying without problem, we decided a switch to 5/16â bolts and sent them to all

Quickie builders without charge. This seemed to cure the problem. Meanwhile we

continued investigation the possible causes for the failures. We were quickly

able to rule out any problem with the bolts themselves. We next turned to examining

how incorrect mounting of the engine might result in the breakages. It has taken

three months and several trips to visit builders, but we think now that we understand

the areas of installation where builders are not exercising sufficient quality

control.

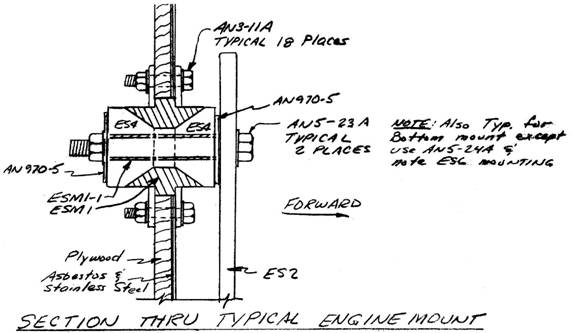

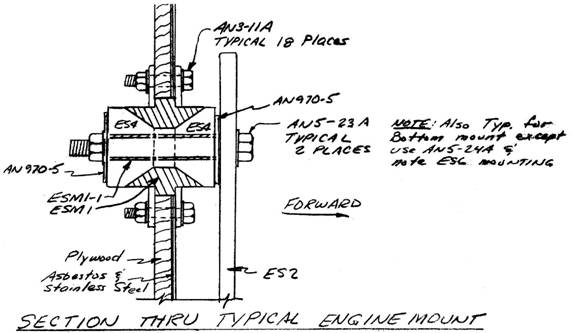

.....In additon, to provide an extra margin of safety, we are making another change to the engine mount assembly, as detailed on page 17â4 and modified by QPC 31. The drawing enclosed here is correct and replaces all previous revisions. This change is mandatory and must by accomplished before any further flying.

.....It is very critical that the engine mount bolts

cinch upon the spacers. If they do not, you can expect much vibration, very high

loads on the system, and possible engine bolt failure. Do not confuse tightening

up on the spacer with running out of threads on the bolt while tightening it

up, however. When you are tight against the spacer, you will feel a distinct

change in the feel of the tightening process since the nut and bolt will want

to turn together. You can verify that you havenât run out of threads instead

by noting how much of the threaded end is projecting from the nut.

.....Note on the drawing that we have turned the

bolts around so that the head is forward. Note carefully the location of

all washers in the system. If, after installing the mount, you think that the

bolts

provided

are too short, you may return them to us at QAC for replacement with longer ones.

.....Be sure to cut the ânippleâ off the end of each rubber mount. That will increase the area of contact.

.....Once you have accomplished all of the items

on the above check list, you can begin to fine-tune your installation. One of

our builders reported that by adjusting the length of his spacers by trial and

error, he was able to significantly improve the vibration level. Working with

the canopy seal will probably improve results.

.....If you have accomplished everything correctly,

the result will be a combination that is as smooth as a CUB, Champ, Cessna 150,

or any other light aircraft. We have verified this not only an N77Q, but also

by

flying several of our builderâs aircraft. One builder, who is a retired airline

captain who last flew a 747, says that his Quickie is very smooth. We have flown

it and agree with him.

ACCIDENT REPORTS

.....Jim Murphy, Cape Canaveral, FL â On

16 October, 1979, Jim Murphy hit a guywire while making an approach

to landing on a four lane highway near Allendale, South Carolina. Low

on fuel, and facing low ceilings and visibilities in all directions,

he decided to land on the highway near a gas station and wait out the

weather. At the time of the accident, Jimâs Quickie had 33 hours of flying time and was enroute to Augusta, GA from St. Augustine, FL. Jim suffered two broken ankles and is now back to work again.

.....After hitting the wire with the left canard

the aircraft cartwheeled onto the nose and onto the highway median. The aircraft

suffered extensive damage back to the aft end of the fuel tank. No fire resulted,

and Jim is considering rebuilding the aircraft. He plans to inspect the remains

further after he has recovered and we hope to get some pictures for examination.

.....Jim is very explicit in wanting everyone to

understand that the accident was his fault and resulted from his inexperience

as a pilot. In fact, the first flying hour Jim had as a private pilot was in

his Quickie! He reports that a crop duster friend is convinced that he would

have been killed flying any other aircraft.

.....Douglas Swanninqson, Kenosha, WI - After

enterring the pattern to land his Quickie, Doug pulled the power back to idle

and began a descent. The engine stopped, and Doug landed about 100 yards short

of the runway in a soy bean field. After touchdown, the aircraft slowed without

problem until it was almost stopped, at which point it turned up on its nose.

Doug was uninjured but was trapped in the cockpit for a few moments.

|