|

BUILDER TIPS

| 1. |

Bending the Orange Foam - The Quickie teas of Al Mullen and Ron Corley report that a small camp stove WOtka well if you keep the foam moving to avoid hot spots.

|

| |

|

| 2. |

Instrument Panel - Quickie builder Doug Swanningson, who should be flying by the time this newsletter i raail.d1 sent us the picture below of his panel layout. Note the several digital readout engine instruments.

|

| |

|

| 3. |

Pitot Tube Installation

- Several builders have asked if it is OK to install the pitot tube prior

to glassing the bottom skin on the canard. This avoids having to grind

through the glass skin later. We agree that this procedure works well.

|

| |

|

| 4. |

Tailwheel Travel - Due to an accumulation of tolerances in the making of the tailwheel assembly parts, a Quickie builder may find that he cannot get sufficient deflection left and right initially. To cure this, wait until the rudder system is hooked up and functioning; then using the rudder deflection template, file the rudder stops on QTW3 to obtain the 30 deg rudder travel called out. If necessary, you may also file the QTW2 fork to a maximum of 1/32 inch to obtain the 30 deg.

|

| |

|

| 5. |

Arm Rest/Aileron Tube

Interference - About 1/3 of the Quickie builders have noted that the

Aileron Tube interf erred with the right arm rest at the seatback bulkhead.

This is moat probably due to an accumulation of tolerances during the

assembly process. To correct, modify the right arm rest contour inboard

so that the tube clear.. if necessary you can glass a bump on the inside

arm rest.

|

| |

|

| 6. |

Pages 4-5 and 4-6 -

Several builders have correctly noted that the red PVC foam included

with the kit is not as thick as the pieces to be made need to be. The

intention was to use scrap orange foam to build up the tickness where

needed. Because the pieces taper in thickness, only a small piece of

orange foam is needed. This also makes it easier to sand when installed

on the aircraft.

|

| |

|

| 7. |

Torque Limits on Prop and Axles - Prop bolts should be tightened to about 75 in-lb unless the wood yields first. Axles bolts should be tightened to about 25 in-lb.

|

| |

|

| 8. |

Quickie Plans Change - abbreviated QPC; These plans changes begin with QPC 1 and continue on, with any recent changes indicated through the Quickie Newsletter. If your QPCâs do not go all the way back to QPC 1, contact QAC for copies.

|

| |

|

| 9. |

Machined & Welded Parts - Some of the prefabricated components shipped are not cad-plated in an effort to maintain kit prices. They should be zinc-chromated by the homebuilder before installation. They do get shipped with a coat of oil to protect them in transit.

|

| |

|

| 10. |

Regulator Grounding - The regulator should be grounded before running the engine.

|

| |

|

| 11. |

Inventory - After receiving

your Quickie Kit, please perform a careful inventory of parts received

against the shipping list. Notify QAC of any discrepancies.

|

|

|

|

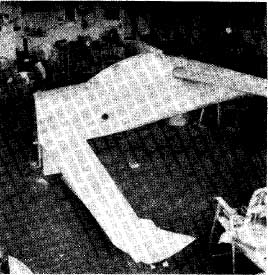

| Robert McFarland nearing completion

|

|

| ... |

|

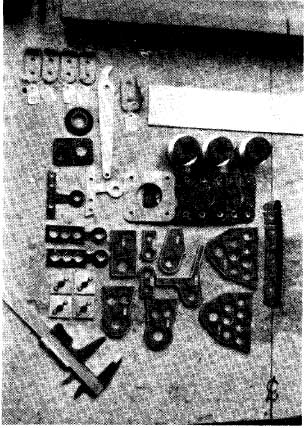

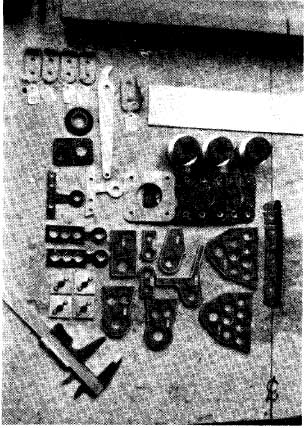

| Some examples

of excellent workmanship by Quickie builder Al Thompson

|

VARIABLE VOLTAGE SUPPLY FOR HOTWIRING

.....We like to use this newsletter to spotlight

developments that may be of interest to Quickie builders. John Watkins and Stephen

Mowry, a pair of Quickie builders from Minnesota, have developed a fine little

Hot Wire power supply kit. We have tested the device in our shop and found it

to

be very good, as well as less expensive than other units that are available.

.....A brief description follows:

HOT

WIRE power supply kit; 0-24 volts, 3 amp, complete kit includes

transformer,

variable voltage control, 10 feet of 24 gauge

nicrome wire, case, mounting hardware, fuse, fuse holder, and instructions.

The cost is $19.95 postpaid from:

Lighting Systems, Inc.

1678 Hewitt

St. Paul, MN 55104 |

|

|