Q2 Plans Chapter 20 Page 20-03

- Details

- Category: Q-2/Q-200 Plans

- Published: Monday, 01 May 2006 20:05

- Written by Quickie Aircraft Corporation

- Hits: 3701

|

CARBURETOR AIR INLET

..... Cut a round hole in the lower cowling for the carburetor air inlet. Fabricate a round tube by laminating 4 BID around a bottle such that the tube will slip over the end of the alternate air source. (Don't forget to use vaseline on the bottle so the lamination can be removed). Bond the tube to the lower cowling carburetor air inlet hole. The result will be a direct ram air flow into the carburetor.  CANOPY RETENTION

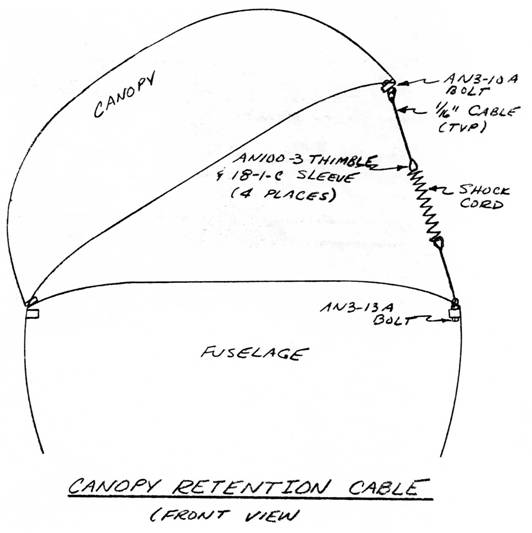

..... It is advisable to have some form of restraint for an open canopy besides permitting it to rest on the main wing. Otherwise,in case of a strong wind, the canopy may be blown off of the aircraft. .....The illustration shows a simple shock cord arrangement. The cable is sized so that the canopy will remain open with tension against the shock cord. This will require the canopy to be open approximately 90 degrees. .....A more clever solution is to purchase a small gas spring assembly (such as those on automobile hatchbacks) and install it on the aft canopy bulkhead and the seat¬back bulkhead. This is the ultimate in sex appeal!  COCKPIT AIR VENTS

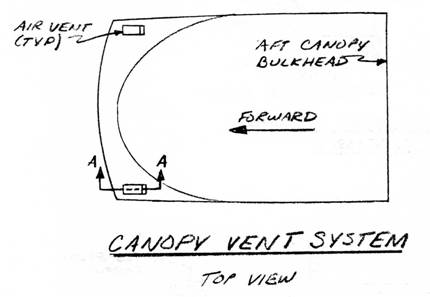

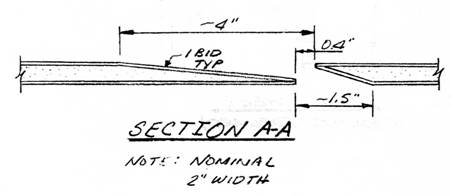

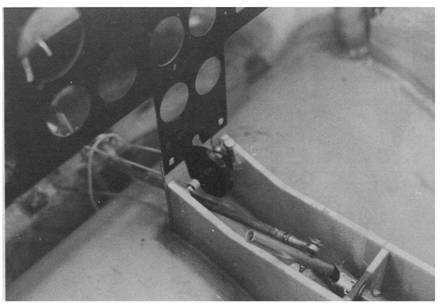

..... A cockpit air vent on either side of the fuselage must be installed prior to first flight. A simple shape, and recommended location, is shown in the sketches. .....To exhaust the cockpit air, a hole could be cut in the tailcone, or else an exhaust vent could be cut in the aft top fuselage.   PITCH TRIM SYSTEM TENSION

..... While writing Section II of these plans, and building N81QA, we built a simple system to vary the tension, or drag, on the pitch trim wheel. .....Make a third TS-1 bearing from phenolic. Drill a 3/8" diameter hole as shown. Next, saw-cut the bearing through the hole, but do not go all the way through and make. two pieces. The lower half of TS-1 is bonded with resin to the end TS-1 bearing already mounted. Do not bond the top half or the system will not function. .....Study the sketch. By turning the screw, the size of the 3/8" hole can be varied slightly, changing the tension on the pitch trim drum. A knob bonded to the screw would make tension adjustable in flight.  |

||||

CONTINUED ON NEXT PAGE |

||||

PAGE

20-3 |

||||