Q-talk 98 - Corrosion Protection

- Details

- Category: Q-Talk Articles

- Published: Wednesday, 23 December 2009 16:24

- Written by Terry Crouch

- Hits: 2545

Q-Talk: There have been recent concerns in lite Varieze community that lias brought to light some issues with aluminum corrosion in the wing attach points. Rutan has suggested grounding or reducing G-loads until a fix could be determined. Are there similar problems that can occur with various Quickie/Q2xx designs that we need to be aware of?

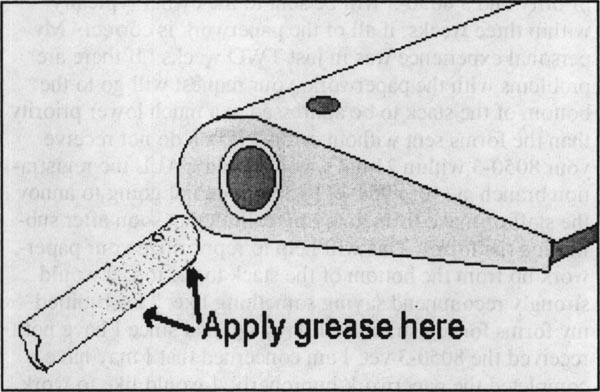

Terry: Since the Quickie and Q2x.x w ings are glassed on there really isn't a corrosion problem with the way they are attached. The control surfaces and associated linkages, however. have been a problem for some aircraft. One tiling every pilot should do as part of the condition inspection is to remove all of the control surfaces and inspect the torque tubes and linkages that drive each of those surfaces. You should apply a light grease or white lithium grease to the steel tubing that slides inside the aluminum torque tubes of the control surfaces. Remember, that under the right conditions. dissimilar metals that touch can create electrolysis and cause corrosion, if left unchecked. Removal and inspection should be done on a yearly basis. If your airplane sits outside in a coastal area, it should be done more often than that. Applying the grease should help reduce the tendency to corrode. It w ill also make it easier to disassemble the controls at your next annual or in the event you have a problem and removal is necessary for the repair.

This isn't just a Quickie problem. A Cessna 150 tliat sits outside all the time can hav e its elev ator pivot points rust solid, if neglected. Ev en oillite bushings w ill dry out after sev eral years if they are not lubricated.. First, the bushing will lock up. Then it w ill start turning in the elevator sheet metal assembly . Pretty soon it will become elongated and worn out. It just conies down to a maintenance issue with all of these planes.

You can order a printed copy of Q-talk #98 by using the Q-talk Back Issue Order Page.