Q2 Plans Chapter 10 Page 10-02

- Details

- Category: Q-2/Q-200 Plans

- Published: Sunday, 21 May 2006 10:05

- Written by Quickie Aircraft Corporation

- Hits: 5801

|

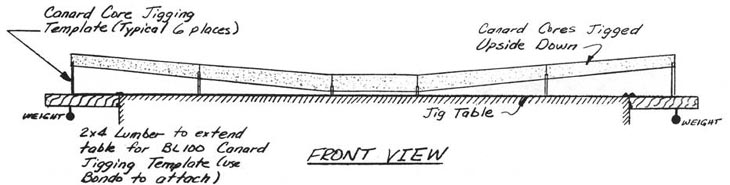

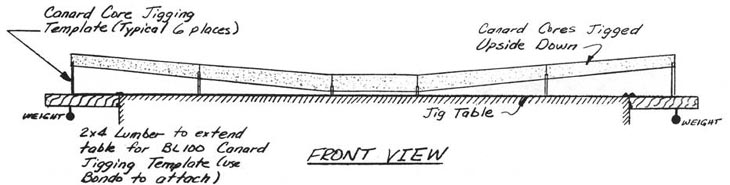

JIGGING THE CANARD

..... Next, you will need to jig the canard cores on the jig table. It would probably be a good idea to clean off the jig table of any bondo chips, wood, epoxy, etc., so that you start with a clean surface. .....Find the canard core female jigging templates (6) .....Now study the sketches. The canard cores are jigged upside down on the jigging table using the canard core female jigging templates. If your table is not at least 200 inches long, you will have to extend it like you did on jigging the main wing. As on the main wing, the shear web is perpendicular to WLOO, and the canard core female jigging templates have leading and trailing edges that are tangent, respectively, with the leading edges of the canard, and the canard shear web. .....Begin by drawing a straight line along your jigging table and marking the locations (BL's) of the canard core female jigging templates. Next, temporarily set the cahard core female jigging templates on the jigging table .so that their trailing edges are the distances from the straight line, called out in the accompanying illustrations. Note that the outboard canard core female jigging templates (the ones at BL100 right and BL100 left) are right on the straight line. A string stretched spanwise with a weight attached at either end may be helpful in establishing and keeping the straight line. .....Now begin to trial fit the five canard cores into position. Be careful in handling the foam cores to prevent damage to the foam. All cores may have to be sanded in order to make them fit together within the maximum tolerance of 1/16". The canard center section core is already beveled to compensate for the anhedral angle, but it may still have to be trimmed and sanded to obtain the fit on the joint within 1/16". The level lines on all cores must remain level at all times. This is important, so take your time. .....Stand back and sight spanwise along the canard to verify that the canard is straight, and is not bowed or kinked. Verify that the leading edges are straight, and that the trailing edges are straight also. .....Don't be concerned if the canard core female jigging templates need to be moved inboard or outboard to remove any bows or kinks. Also, a long straight edge will help you looking for kinks and joggles, or dips. .....When everything is perfect, mix up some bon do and carefully bondo the canard core female jigging templates to the table top in the necessary location. Next, rest the canard cores on the canard core female jigging templates. Check the alignment and individual level lines again; then again and again until every thing is Perfect, with a capital P. The next step is to join the foam cores together with micro slurry after verifying that the core fit is within 1716". Check, recheck, and re-recheck each core level line and alignment as the cores are joined. Note that the canard center section foam core gets a glass rib of 2 BID and flox corners at each end of the canard center section foam core. The flox corner should be added after the entire series of canard cores have been joined and cured.

PREPARING THE CANARD CORES FOR GLASSING

..... .....At this point, the canard cores should be jigged on your jigging table upside down, 5-minuted and bondoed in place, and able to take a direct hit from a 88 mm howitzer without budging from its location. .....Use a hard block to clean up all joggles, excess micro, and any bumps on the canard cores. At either end of the canard center section core, round the joint so that the glass will flow smoothly across the joint. At the T.E. (shear web), round the corner so that the glass will flow smoothly down the face of the shear web. .....This is your last chance to do it right, so spend at least another hour making these cores as perfect as you know how. While your at it, check, recheck, and re-recheck all the canard level lines that you can see until you can do it in your sleep. If you are not proud of everything sitting on that jig table, don't go on to the next step until you are.   |

|||||||

|

|||||||

PAGE

10-2 |

|||||||