Q-talk 140 - Measuring Epoxy

- Details

- Category: Q-Talk Articles

- Published: Thursday, 29 April 2010 20:03

- Written by Dan Yager

- Hits: 4123

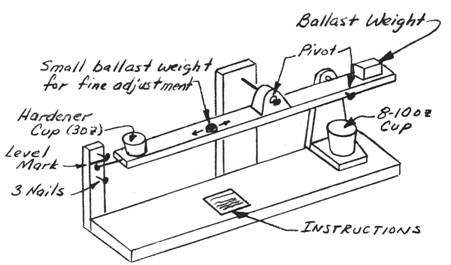

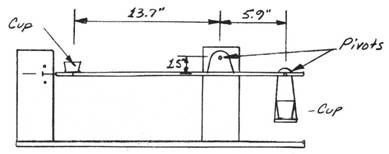

When I first started looking at the plans to rebuild my Q-200, I was amazed at the lack of description and clear instructions for some very basic things. In fact, one of the MOST basic things that we all need to learn is how to properly proportion epoxy. The description of the balance beam and proportioning system takes up about half a page of the Education chapter in the Quickie and Q2 plans. In fact, the only description given about how to perform the proper proportioning appears below:

|

Epoxy Balance Devices which automatically ratio the correct amount of resin and hardener and dispense it with the pull of a lever are available from Aircraft Spruce & Speciality Co., and Wicks Aircraft Supply, for approximately $150. These save time and epoxy. You can ratio the epoxy by building the following simple balance - don't skip steps! Follow each step exactly every time you mix epoxy.

|

||||||||||||||||||||||||||||||

That's it! There's really no description of what materials are used to create the balance, other than "metal tube bushings in wood." Hmm? That's not very helpful. . .Am I building this thing out of 2x4's or toothpicks? Also, how long will it take me to build it? I know this airplane just throws together, but do I really want to waste about 4 hours of my precious build time on something that ultimately won't end up in my plane?

The plans also mention epoxy proportioning pumps available from Aircraft Spruce and Wicks for a mere $150. This was 1977 folks! If that didn't scare you into figuring out how to create one of those balances I don't know what would. Also not mentioned is how to change the mix ratio if the RAF epoxy system is suddenly no longer manufactured?

Needless to say, this is one of those places where I definitely thought, "There's got to be a better way!" The video below shows a quick view of the way I proportion my epoxy (with a brief description to follow):

{flv}qtalk/Measure_Epoxy{/flv}

Instead of building a scale from pieces of lumber and scrap metal, I simply went and bought a very reasonably priced ($10) jewelers scale from Harbor Freight Tools.

The scale is great since if you place the cup on it, and then turn on the power, it automatically "Zeroes" itself so that the weight of the cup is nullified.

So you simply follow these steps:

- Place the cup on the scale and turn it on, making sure that the scale is "Zeroed."

- Add an appropriate amount of resin for the part your trying to build.

-

Because I'm using Aeropoxy the ratio of hardener to resin is 27 to 100 by weight. That means you simply multiply the weight of the resin by 1.27 to get the total weight of the resin and hardener together. In the video example, that would look something like this:

..................................................................19g x 1.27 = 24.13g - So you simply add hardener until the total weight equals 24.13g

- Then use a mixing stick to mix everything thoroughly and your ready to pour!

The beauty of this system is that it is EXTREMELY ACCURATE right out of the box with absolutely no build time wasted. The scale measures in several units including Grams, Ounces, and Carrats (for those of us that are working on a diamond in the rough.) In addition, you only use a single cup, so you kill fewer trees than we were concerned about in 1977.

Like I said, I bought my scale from Harbor Freight, but they are also available online from Amazon and eBay if you're interested in getting an even better deal.

If your epoxy system uses a different ratio, ensure that you use the WEIGHT ratio, and NOT the volume ratio. Simply divide the small number, by the big one, and add one. So for example if your ratio was 36 to 103 by WEIGHT:

36/103 = 0.3495

0.3495 + 1 = 1.3495

Then you simply multiply the WEIGHT of your resin by 1.3495 and add hardener until your totalWEIGHT matches the result.

The plans are full of holes like this, so if you can think of a great way tomaintain the intent of the plans while at the same time updating them and making them simpler and more clear I encourage you to write an article for the next issue of Q-talk. I'm curious to see what others will come up with!

As always I invite your feedback below or in the forums.