Q2 Plans Chapter 10 Page 10-01

- Details

- Category: Q-2/Q-200 Plans

- Published: Sunday, 21 May 2006 10:05

- Written by Quickie Aircraft Corporation

- Hits: 6148

|

CANARD CONSTRUCTION INTRODUCTION

..... The Q2 canard has a swept leading edge, swept trailing edge, anhedral, a plain elevator which also effectively serves as a flap, and, in addition to carrying about 65% of the aircraft's weight, also provides the energy absorption (i.e. IIspringll) for the main landing gear that is mounted at the canard tips. It is a sandwich composite structure with solid foam core, two layers of UNI at 45 degrees to the trailing edge of the canard for torsional stiffness and surface durability, and spanwise tapes of UNI for bending strength. Shear loads are taken by a vertical shear web, and the elevators are essentially fullspan, being actuated by an aluminum torque tube. .....The canard is constructed in one piece from tip to tip for stre_gth, lightness, and ease of construction. .....Because of these factors, the canard is more complex and more critical than the main wing. However, the basic procedures are identical, and the experience you have gained in completing the main wing for your Q2 should allow you to construct the canard in the same amount of time. You may wish to reread the chapter on the MAIN WING to review the procedures. CUTTING THE SPAR CAPS

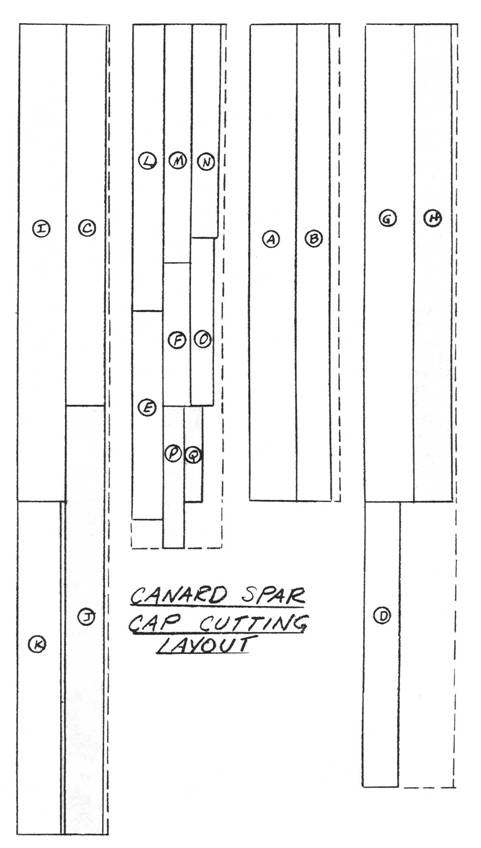

..... Begin by cutting the UNI spar caps using the suggested layout on this page. Letter each one of them with a felt tipped marker for identification later, in addition to marking a centerline in the middle (where the cap will cross BLOO when installed on the canard. Be sure to carefully roll up and store the spar caps after cutting to prevent damage. GLASSING THE ELEVATOR SLOT FOAM CORE SLOTS

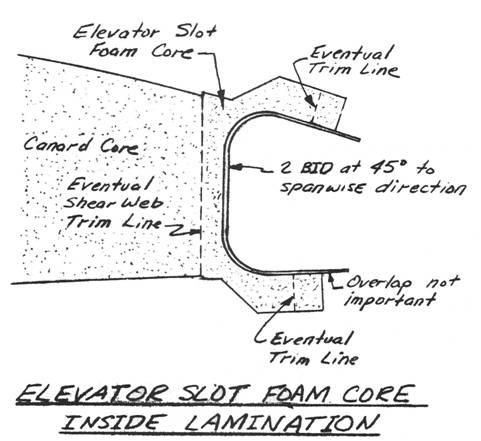

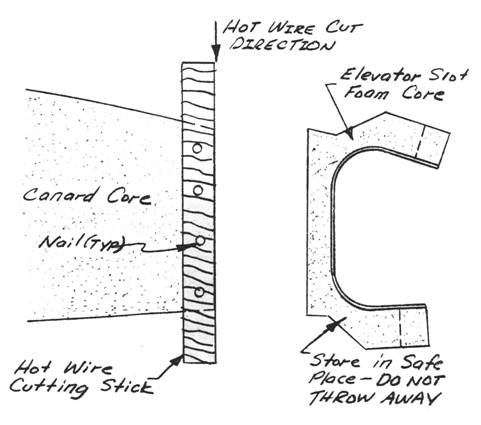

..... Construction begins by glassing the inside slot of the elevator slot foam cores with 2 BID at 45 degrees to the spanwise direction (i.e. T.E.). Knife trim to the edge of the foam core. .....Next, get out your hot-wire cutting equipment and set it up. Take the forward part of each canard core templates, and nail them back onto the already hotwired cores, being sure to check the level lines and to weight down the cores. Then, hot-wire the 51-A-B-C H-I-J-48 sections on all canard foam cores. Store the elevator slot foam cores for later use.    |

||||

|

||||

PAGE

10-1 |

||||