Q-talk 28 - ODDS and ENDS

- Details

- Category: Q-Talk Articles

- Published: Tuesday, 30 April 1991 07:11

- Written by Jim Masal

- Hits: 2483

Congrats to builders of three new birds that have hatched recently: Dave McConahy (Q2), Bixby, OK; Bill Varga (Tri-Q), Fairview Park, OH; and Bob Falkiner (Q2), Ontario, Canada. After leaving an excited post-first-flight message on my recorder, Bob and I later had a "downer" conversation. He got in several hours of flight during which he admitted to having whacked the thing in on a couple of landings. His last landing was a hard one too, followed a brief moment later by a sag to the ground as his carbon fiber spar broke near the fuselage. We know from past performances that he's a good writer so I look forward to a promised report on his disaster. He was expecting to be on the Oshkosh flightline too.

Quickie builders!!!!!! Run, don't walk to your post office with a letter to Bill Archer, 290 Columbia 36, Magnolia, AR 71753 or call (501) 234-7983. Why? In a frivolous fit of misguided passion, Bill undertook the thankless job of writing an excellent INDEX to all the Q-TALK issues pertaining to the Quickie. This is quite a nice looking and handy compilation. Regrets to you two-place types ... his passion didn't last that long.

Don Admire, long involved with his Q2, recently destroyed his Tri-Q conversion. Word from Padios is that he came in to land, bounced 3 times and went knife-edged after the third, recovered too late and SPLAT! Don's OK and the plane is repairable but he's planning to scrap it. Reportedly Don had only 10 hours or so of flight time in it over the last 5 years.

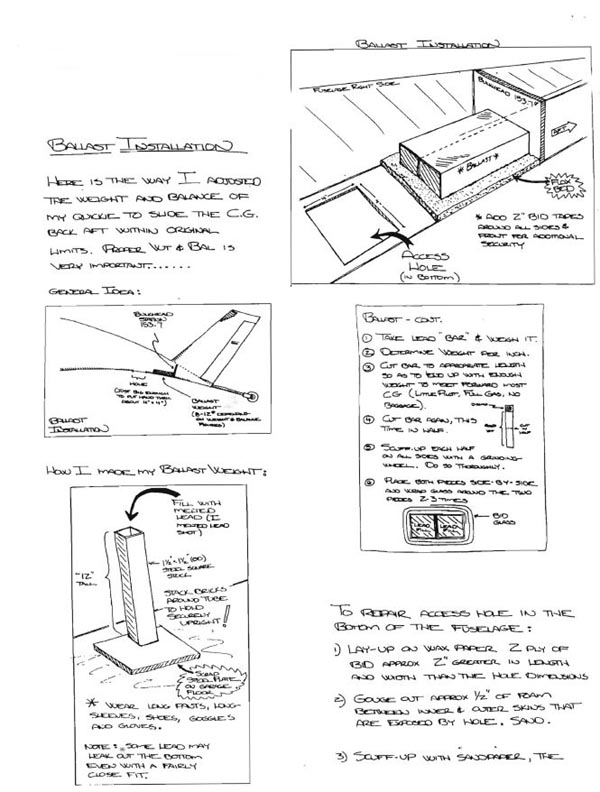

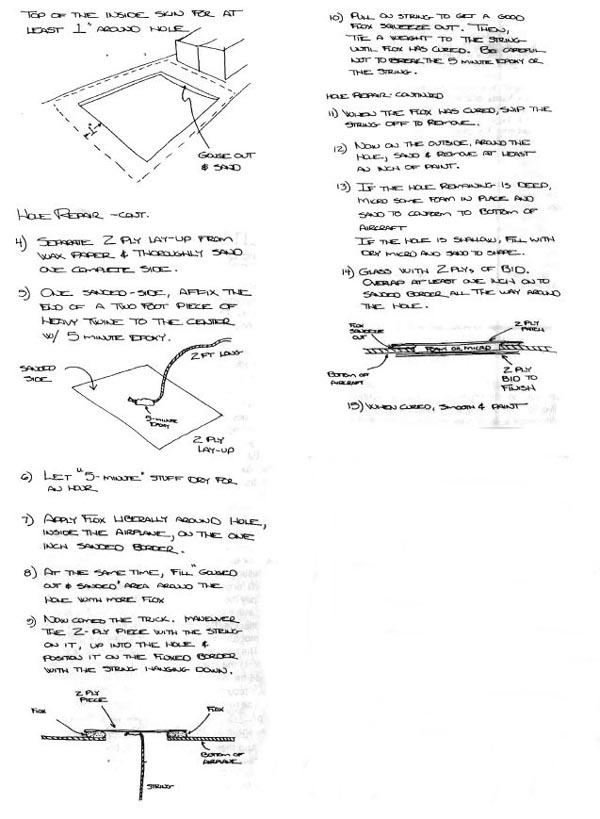

More from Jinx Hawks and Brock McCaman on their successful conversion to the Rotax 503's:

Dear Jim,

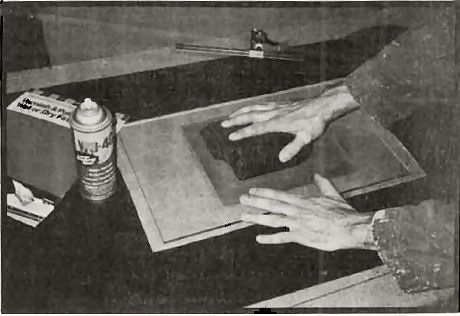

A problem most homebuilders are faced with, one time or another is warped castings, such as cylinder heads, oil pump covers & housings, carburetor mating surfaces, etc. The result of which usually is leakage of the substance being sealed. In an effort to avoid expensive machine shop trips, or the make-do approach of trying to file the surfaces flat, I devised an alternative. The process is very simple, requiring no special skills or tools. Basically, it is a method of block sanding or lapping the surface to a very critically flat degree, within .001", with a minimum of material removal.

First, you need a very flat surface to sand or lap on. It should be large enough to accommodate the surface to be trued up. I use the 1/4" thick glass of my coffee table. Surprised? Most flat glass is very accurately flat. Check yours out with a straight edge before using it. The thicker the better to lessen your chances of error due to deflection. If I were buying a piece I think I would opt for 1/2" thick plate glass because it would be very stiff and hard, allowing a direct lap with lapping compound. The glass should be properly supported on a flat table with a layer of corrugated cardboard or something similar between the glass and the table. Now that you have a good flat surface on which to work, you need the cutting media to go between this surface and the one, which is not flat. To preserve the condition and appearance of the glass, I usually use wet or dry silicone carbide sandpaper. It helps to spray the glass with WD-40 to help the paper to stick and also on the cutting side to make things work smoothly. Grit should be determined by degree of warpage and final finish desired. If the part is too large for the sheet of sandpaper, you may be forced to use lapping compound directly on the glass. Once set up, you are ready to resurface the part. For an even removal of material, use a figure eight motion as you rub your part around on the glass. Check your progress frequently with an accurate straight edge and your feeler gauge. Happy Building!!!

Bill Archer, Magnolia, AR

Dear Jim,

Still no pictures of my airplane for you, but I thought I'd update you on my experience with my Rotax Quickie. First, I would recommend an adjustable prop due to the drastic difference a small pitch change makes in the engine performance. (Hence the ad for a prop in the classifieds.) I've got about a hundred hours on my airplane and I've found the Rotax to be a little different to operate than 4-stroke engines. Do not do partial power descents. The owner's manual mentions this and I'd like to strongly reinforce it. Our airplanes are slick and will really windmill the little Rotax. My procedure upon arrivals is to pull power back to idle and slow the plane to 80 to descend. Give the engine a good healthy shot of throttle every 10 seconds or so to keep the bottom end lubricated. I get good throttle response with this method. Do a fast, low-power descent and she may or may not answer when you need some power. Someone from the Mini-Max people mentioned that you should pull the cylinders every 50 hours and clean the pistons and rings. I strongly agree on this. Take the pistons and rings (keep them in order) down to your local shop and soak them in carb cleaner. Works great! Another trick is to clean the air filter regularly. My carbs spit back a little fuel and the filter becomes oil soaked after awhile. This knocks off the power a little. Seems like I need to do this about every 15-20 hours.

I put in a removable fuel tank per Jinx Hawk's plans that holds about 3 1/2 gallons and I'm very happy with it. It really increases the utility and safety margins. Also, I flew through some fairly heavy rain for the first time last week and I can vouch for the vortex generators if you have the GU canard. No pitch change at all but rain sure slows down the airplane.

I'm going to try something this year on the control surfaces. Some people have had trouble with the center elevator hinge wearing out, so at annual this spring I pulled the elevators and ailerons and greased the hinges. I plan to do it annually if it looks like it's working. It's some extra work but sounds a lot easier than replacing hinges.

I'm hoping to hit a few airshows this summer now that I think I've got the Rotax figured out. Now if I could just figure out how to land the same every time. If any of you see the Quickie with the pink strip and chicken pilot, come give me a hard time about it.

Robert Bounds, Grant, NB

A LITTLE MARIJUANA GOES A LONG WAY

Pilots are not supposed to smoke dope. But some do. Traces of marijuana turn up all too often in the blood of those killed in accidents. The reason may be that marijuana has a negative effect on piloting skills long after the sense of being high has gone.

This potentially fatal prolonged effect was revealed in a recent study of 10 experienced private pilots. Their mean age was 29, and they had an average of 303 hours total flight time. All the volunteer subjects were experienced marijuana smokers, though each used it less than daily and each agreed not to smoke dope or take other drugs during the period of the experiment except for what was provided as part of the testing procedure.

Each person received eight hours of training on a visual simulator set up to mimic a Cessna 172. The simulator was heavily instrumented, with all data being fed into computers for later analysis. Measurements were taken of every control yoke and throttle movement as well as data determining where the "plane" was at certain critical portions of flight.

The test maneuver called for a takeoff, climb to 700 feet, two turns, descent and landing. Pilots were instructed to treat the task as though it were an FAA check flight. On the day of the testing, each person first took two practice flights, which weren't recorded, and then one baseline flight, which was recorded. They then smoked an official National Institute of Drug Abuse joint, with a known amount (19 mg) of THC, the active ingredient in marijuana. This amount of THC was rated by the investigators as "probably the equivalent of a strong social dose".

The test pilots then reflew the profile, once at one hour after smoking the marijuana and again three hours later. They returned the next morning, again took two practice flights, then flew a recorded flight 24 hours after they'd smoked.

The results were startling. A day after smoking marijuana, the pilots reported no feeling of being high nor of being less alert, more anxious or more happy. They were, they felt, quite normal.

And therein lies the problem, because their performance certainly wasn't normal. On the baseline flight, they landed an average of 12 feet off the centerline of the runway. That increased to 32 feet an hour after marijuana ingestion, and was 24 feet - double the baseline measurement - a day later. One pilot landed completely off the runway in his day-after flight

As shown in the table below, there were considerable degradations of all piloting skills after smoking marijuana, and these persisted for 24 hours - long after the time in which a pilot perceived there was any effect from his chemical trip.

"The difficulty the subjects experienced in aligning and landing precisely at the center of the runway is particular cause for concern" wrote the investigators, who were from California's Stanford University and the Naval Air Station, Moffett Field. "It is important to note that the near-doubling of lateral deviation on a landing at 24 hours may be an extremely serious error. In actual flight, where there is wind and turbulence, such errors can easily lead to crashes.

"These results suggest a need for concern about the performance of those entrusted with complex behavioral and cognitive tasks within at least 24 hours after smoking marijuana, " the researchers stated.

DAY-AFTER EFFECT OF MARIJUANA (AVERAGE OF MEASUREMENTS ON 10 PILOTS) | ||||

| Time after marijuana ingesting | Baseline | 1 Hr. | 4 Hrs. | 24 Hrs. |

| Distance off-center on landing | 12 | 32 | 29 | 24 |

| Lateral deviation from localizer | 19 | 56 | 45 | 34 |

| Vertical deviation from glideslope | 26 | 61 | 45 | 40 |

| Number of aileron changes | 60 | 102 | 82 | 76 |

| Number of elevator changes | 264 | 361 | 306 | 285 |

| Number of throttle changes | 22 | 29 | 27 | 25 |

Dear Jim:

My "reliable source" informed me that the 20 Hp Teledyne is not available yet, but that the 18 Hp engine is. So I called Teledyne and was told, no, nothing is available yet ... look for the 16 Hp and 18 Hp engines first quarter of next year, and 20 HP isn't yet in development. So much for dealers! The engines have run into production delays, but some dealers (like mine!) are willing to take your money and then stall you without telling you what's really going on. The engines are called the Wisconsin Robin Sovereign series.

Contact: Teledyne Total Power Systems, 3409 Democrat Road, P. O. Box 181160, Memphis, TN 38181. (800) 932-2858.

Briggs & Stratton, on the other hand, is shipping the 16 Hp engine and promises the 18 Hp this fall. They are adamant about NOT selling to airplane people, though. They have turned down an OEM order for 200 engines for airplane use, and sued one guy for misrepresentation when they found out that he had lied about the engine's intended use and put it on an airplane instead of whatever he had said it was for. And one guy put a Briggs on an airplane and flew it into the ground doing aerobatics with the stock float carb and gravity feed fuel system! At least, that's what John McNamara of Spencer Engines in Tampa (a Briggs & Stratton dealer: (813) 253-6035) has told me. Briggs & Stratton's OEM rep. for this area, Steve Vecchio, would not even confirm that Briggs makes engines when he found out that I wanted one for an airplane.

Wanna "Buy American"? Here's your chance. Currently the Briggs is only available in 16 Hp but 18 Hp is in the works. The 16 HP engine complete with starter, electronic ignition, and 16-amp alternator and regulator is available for $689.95 from Northern Hydraulics in Minnesota. The 18 Hp Briggs and the Teledyne engines should be under $1000 almost anywhere when they become available. Teledyne's similarly equipped engines will be rated for 3000 hours! Say THAT about a Rotax!! (I know, the Onan was supposed to be good for 1000 hours. But it wasn't supposed to be baked to death, either.) Of course, if you prefer imports, Kawasaki and others have similar offerings, and other American firms like Kohler, Tecumseh and Clinton are jumping on the bandwagon. Now all we need is a guinea pig ... I've got a date with a Revmaster and an Onan. Brock? Jinx? Naw, they've done more than their share already. How about one of the other "new" guys ...?

My feeling is that the Onan is a perfectly good engine choice for the Quickie. The problem is in the installation, specifically the cowl and baffles. What we've needed since day one is a properly engineered cowl, not a Gene Sheehan special. If QAC had acted like RAF and made a mandatory change to a properly engineered cowl, the Onan's reputation would not have been so badly sullied and we'd have had the reliability that QAC advertised. The fact that the problem is with the cowl, NOT the engine, has been lost on so many people that the mere suggestion of fixing the Onan installation brings howls and jeers. So the only way to rectify the situation is to force a change. Converting to new engines is the catalyst for this change. Besides adding new features like electric start capability and electronic ignition (also available for Onans) the adoption of new engines will require new cowls, and retaining the stock fan and shroud will minimize the task of new cowl and baffle design. The lighter weight of these new engines makes this possible.

Were the new engines to be installed in the same manner as the Onan, i.e. stripped of fan, shroud and starter, the weight savings could be significant. Plus, removing the fan makes more horsepower available at the prop. Unfortunately, I fear that the QAC cowl would be used as a template for cowl and baffle design that would lead to the same problems with the new engines as experienced with the Onan. This, I predict, is about to happen to the guys who are trying to cowl free air Rotaxes without the fan. Whenever I hear mention of "negative pressure" or "bring the air in at high speed" I cringe. That is NOT how a cowl works.

Gene Sheehan knows this, now. Follow the cowl designs from the Quickie through the Q-200 and you'll see a steady improvement in inlet, baffle, and outlet design principles. This may be why Vic Turner refuses to associate with us: Way back when, he developed a neat little cowl and spinner THAT WORKED and offered it to QAC. This cowl (and a similar one developed later by another builder who shared it in Quicktalk) gave 100? cooler cylinder head temps than stack cowls. QAC offered it to us, the builders, for $200, if there was enough interest. There wasn't. If QAC had made this cowl mandatory, a la RAF, we would have moaned and groaned, but ended up with Onans that lived and thrived. Instead, we ignored Vic and now he won't talk to us. And we bitch about the Onan. If we're going to change engine brands let's do it right. For that matter let's get these Onans done right. The stock Quickie cowl does not work and must not be used as a template for any future engine installations.

Look at the Onans that thrive. Look at the cowl that Norm Howell used. Look in the Q-TALK back issues. Look in the QAC newsletter back issues for Vic Turner's cowl. Cowl design is not a black art. The principles that work are in print and have been since 1949. C.A.A. Technical Manual No. 107 reprinted by the EAA as "Aircraft Powerplant Handbook," Chapter 15, "Powerplant Installation," Page 208-210, "Cooling System," gives a basic overview of how cowls work, and should be mandatory reading for Quickie owners. Would-be cowl designers can get more specific information from a variety of sources, but the most convenient source I've found is Hoerner's "Fluid Dynamic Drag".

The stock Quickie cowl violates most basic principles of cowl design. Where the inlets are supposed to be small compared to the Pressure Box, the Quickie's inlets are large. Where the Pressure Box is supposed to slow the air and convert its dynamic pressure to static pressure with little turbulence, the stock Quickie cowl (especially with Anderson-Little mods; sorry guys!), just let's it keep tumbling along, and where the Expansion Chamber is supposed to be, the Quickie cowl has none. Anyone who attempts an engine installation using the stock cowl as a template WILL meet with the same problems as the Onan installation. In fact, many of the problems with the Revmaster installation in the Q2 stem from the same cowl design errors, but, because of the Revmasters success in other designs, the engine wasn't blamed as much and people found ways to make it live, though not comfortably. Still, the big change to Continental power was undertaken by many, who found themselves facing the same problems again! Not until the Q-200 did things start to work as advertised.

Don't get excited and confused over these alternative engines. Get excited about the new cowl designs they'll spawn. The cowl is the key, and done right the Onan offers greater potential power than the new engines, at least until the introduction of the 20 HP versions of the new engines. The new cowls can be retrofitted, or their principles applied to Onan installations, once they prove their worth.

Until the cowl is done correctly, however, the Onan guys will only be getting 16 Hp or so, even out of their supposedly 22.5 Hp engines, because the bulletproof little Onan absolutely refuses to fail catastrophically. Instead, when cooked, it starts to leak, and the leaks let it bleed off excess heat until it only puts out as much heat as a 16 Hp Onan, the engine for which the cowl was designed and works acceptably. Of course, for the engine to only put out the heat of a 16 Hp engine requires that it only make 16 Hp. QED. Read between the lines and see why the Onan is such a remarkable GOOD choice: it won't quit!

On another subject, if anyone has a Q2 LS(1)-0417MOD airfoil canard construction and jigging templates for sale, please contact me at (407) 569-5885. I bought a Tri-Q that won't fly and I need these templates to check incidences and find out what's wrong. If anyone can help, please don't delay. My workshop space and helper are only available through August.

I may sound crazy, but I want to convert BACK to a taildragger. The airplane has the extended span wings, but I prefer the stock span so I'll need to do something about the extended span canard. The canard looks good, is modified for less anhedral per the Swing plans, and I'll be checking the washout once I find some templates. If the twist is good, I could just cut off the extensions, but then I'd have to put the anhedral back in for a taildragger. It might be easier just to strip the canard down to the spars or buy new spars and start over. However, if someone wants to convert to tri-gear we may be able to work out a swap ... If anyone's interested, call me NOW! Like I said, I only have 'til the end of August.

I want you to keep doing the QBA thing! You've been doing is SO WELL for over ten years, you're GOOD at it, and WE NEED YOU! Things are just starting to get interesting. Go flying. Then come back and write a scathing editorial aimed at all the guys who's names take up room on the roster but have never appeared on the pages of Q-TALK, and the new guys who think you get paid big bucks. Write about "participatory membership", "voter apathy", and "civic duty". Then make up a new QBA renewal schedule that has six renewal times per year and assign renewal dates accordingly, so you won't be swamped at Christmas. Then watch your mailbox for interesting things.

Keep up the good work, Jim.

David J. Gall (407) 569-5885

ED. NOTE: Humor him, fellas, he's one of the new kids.

You can order a PDF or printed copy of Q-talk #28 by using the Q-talk Back Issue Order Page.