QuickTalk 30 - Q-TIPS

- Details

- Category: Q-Talk Articles

- Published: Friday, 31 October 1986 06:11

- Written by Jim Masal

- Hits: 2730

SAFETY ITEM: A QBAer recently reported a bad experience with a clear glass fuel filter that came with his kit. The filter has a cast potmetal central fixture that screws into the end pieces which are in gasketed contact with the glass tube through which you can view the fuel and filter element. He had two cases where the potmetal fixture broke at the threaded end allowing the end piece to pull out and leak fuel into the cockpit. I noticed that on the filter on my Quickie the central fixture didn't seem to be long enough to deeply engage the end pieces. Perhaps this has been a problem for the manufacturer because these filters, which have been seen at Chief Auto Parts stores, have been redesigned and improved now. Check yours out.

TAILWHEEL: A Q-200 builder has found a pneumatic tailwheel replacement from Aircraft Spruce that he claims gives a better grip to the runway to prevent the skidding around and improve ground control. I didn't get a part number. He claims also that it dampens some of the noise coming up through the tailcone as well. The tailwheel fork has to be spread just a bit to take this softer wheel.

I picked out these items from a recent "Dragonfiles" newsletter:

Builder Ron Price bought 4 gas struts, 10" x 22 lb, for his Dragonfly canopy for $19.62 including UPS charges! This may not be the best strut for us but you could write or call for advice I'm sure:

Creation Windows, Inc.

53132 C.R. 13

P.O. BOX 1046

Elkhart, IN 46515

Call: (219) 262-3577

Oh yeah, forget to mention the fact that you're building an airplane, OK?

Dark colors absorb heat; light colors reflect heat. Think of white as a closed door and black as an open door passing heat both ways. Black items will let heat in if it's hotter on the outside or let it out if it's hotter on the inside. That's why auto radiators are black. A black surface is more than 10 times better in heat radiating ability than a plain cast surface. Flat black and thin coatings are best. Engine cooling can be greatly affected by color. Not only do the cylinders and oil coolers radiate heat, but so does the entire engine. Crankcase, valve covers, EVERYTHING will radiate heat better in black paint. The more efficiently the engine is cooled, the smaller the intakes and the less drag and more performance.

Here's a composite fuel tank sealer you might investigate for your composite "boat": ProSeal 890A-2, available from Products Research and Chemical, PO Box 1800, 5454 San Fernando Rd., Glendale, CA 91209. It's about $10 per qt.

If everything seems to be going well, you obviously don't know what the hell is going on.

PROPELLER CARE NOTES:

Good stuff here taken from Sport Pilot, Sept./Oct. '86, "Proper Care and Feeding of the Modern Propeller" by James Lawrence, (an interview of The Great American Propeller Co. folks):

1. Never force a prop to fit. The bolts should fit holes snugly BUT THAT'S ALL. Wood swells in moist climates and dehydrates in dry ones. Whatever you do, don't knock it on with a hammer or pry it off with a screwdriver.

2. Always have a full size crush plate on the prop hub to distribute bearing loads. Use wide area washers on prop bolts.

3. Torque prop bolts properly with an accurate torque wrench. Check FAA publication AC 65 for bolt torque specs. Though some new props can withstand 40 ft/lbs torque, a 3/8 bolt will only take about 25. Install bolts in a cross tightening sequence. Retorque after the first flight, the first 10 hours and every 25 hr. thereafter.

4. Absolutely NO foreign material must be between the prop and engine flange. Paint chips etc, will throw prop tracking off.

5. Track your prop or expect BAD VIBES. To track: tape or fix a stick or stiff object to the wing (NOT on the ground, because the plane can move). Place the end of the tracking stick within 1/16" of a blade tip, mark it, then rotate the other blade to the same position. The distance from tip to stick and the alignment of the prop arc should be the same. If not, check for foreign material under the prop or on the flange. If the misalignment is minor, loosen the bolts and start over using differential tightening. You can use up to 4 lbs. more torque on one side than the other, but you must stay within your bolt torquing limits. Pulling the prop off and rotating it to a different position, then retightening can sometimes help.

6. Wax your prop. The slicker it is, the less hits it will take, believe it or not. In an average or slightly rough prop, a rock can make a 1/8" dent whereas the same rock would make only a 1/16" dent in a slick prop.

7. Don't fly even a slightly damaged prop. Seal the damage immediately with epoxy or a 2-part glue. Keep moisture out of it. Any dent or disturbance in the prop can set up as much as a 30 degree fan or wake of turbulence behind it.

8. Protect it from the sun. Use a prop cover outside. All wood has moisture. Great American Propeller's blanks have an 8-9% moisture content on an average day. Keep wooden props horizontal at all times. Never stand one in a corner for any length of time or the moisture will migrate and the prop will go permanently out of balance. Keep prop on the floor or hanging horizontally.

9. Inspect for the color gray in the wood that signals dry rot.

10. Don't automatically trash a badly damaged prop. It may be 100% restorable at a fraction of the cost of a new one.

From Steven Whiteside #2439, Ringwood, NJ

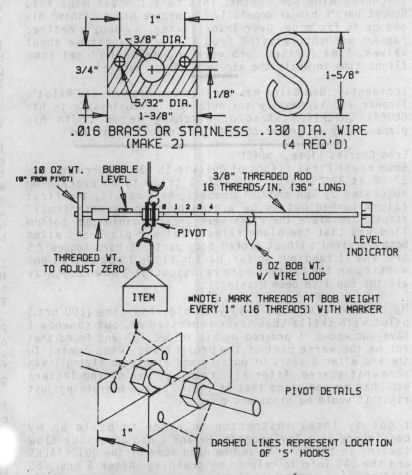

Enclosed is a simple-to-build beam balance that will give good service, I believe. What you see is model 3 or so. The whole list of parts total about $8.00 and if there is enough interest, I could supply them as a kit. It is as accurate as the calibration. With a little modification (adding a second 8 oz. plumb bob) one could extend the range up to 50 lbs., but I haven't tested it, and I'm not sure the .016 brass would stay straight.

I have found single jack chain (half-twist, figure-eight links) to be extremely uniform from link to link. K-Mart usually has this and I highly recommend using lengths of it for epoxy balance calibration or testing. It is much easier to measure a length of chain than it is to count nails (besides, the nails I checked weren't very uniform). I used a reloading scale to test a lot of possibilities before I found the chain.

You can order a PDF or printed copy of QuickTalk #30 by using the Q-talk Back Issue Order Page.