QuickTalk 11 - Q-TIPS

- Details

- Category: Q-Talk Articles

- Published: Wednesday, 31 August 1983 07:11

- Written by Jim Masal

- Hits: 2813

I hollowed out a small area in the upper center of my seat back bulkhead and epoxyed in a bubble level tube so that I can always level the plane laterally. The tube is only 1/4" x 3/4".

My hotwire unit is probably different than most. I bent 3/4" thin wall conduit to appropriate dimensions and stretched the safety wire like a bow using plastic strip to insulate it. I then ran one wire through the conduit to join the second one on the base end and terminated it in a standard two-prong household plug. I also mounted multiple sockets on a piece of plywood, so I could insert multiple light bulbs in series with the hot wire. I found 700 watts of bulbs in series with the wire was just right. With the correct circuitry and a dry basement, it works well. A three-prong to the power source keeps the wire on the ground side of the 'ballast'. (Henry Hurd, #2533)

When assembling metal assemblies, you may find that the diameter of the piece you are inserting is a trifle too large and sanding is required. Take a full sheet of 100 grit and 320 grit sandpaper and cut a long strip off each sheet. You will be able to grip the ends with each hand like you would grip a piece of cloth to shine your shoes. Put your metal piece in a vise (protected by pieces of wood) and begin pulling your sandpaper back and forth as you would when shining the tip of your shoe. By moving around as you sand, you will soon have your piece down to the correct size. Do most of the sanding with 100 grit and finish with 320 grit. (Phillip Kelly, #2409)

I had trouble with holes going out of round when drilling tube, so I bought 1/8" and 3/16" straight reamers with a 45-degree cutting lead. It works well reaming a 5/32" hole to 3/16", however reamers will cut sideways. To overcome this, I dulled the cutting edges with a Dremel except for the first 1/8", so it now operates like a twist drill, except it has four cutting edges instead of two. With four cutting surfaces, there is no tendency to cut oblong, oversize or out of round holes for AN3 bolts. (Bob Falkiner, #2015-Can.)

Let me add to the SAFE-T-POXY controversy. I came up with a cortisone prescription product called 'Triamcinolone Acetonide Cream 0.1%, USP'. This helped a lot to relieve the itching and burning discomfort. I also reduced the length of time for each layup and changed gloves and liners more often. (Dick Pratt, #2192)

After a night of fooling around with line levels and not being satisfied with the results, my partner suggested that we borrow an optical (Wye) level from work. Not everyone has access to this kind of instrument, but if at all possible, try to use one as they are far superior to line levels.

We are covering our layups with plastic and squeegeeing out any air bubbles and excess epoxy. There has been absolutely no problem with air bubbles, our surface finishes are much better with the plastic than without and our weights compare favorably with QBA's figures. (Peter Borozan, #2788)

During layups, I use a product called Zeasorb (a talc-like powder, but more absorbent) to sprinkle on my hands and inside my gloves. (E.T. Mueller, #2310)

A simple leveling device that can be used by one person is to take a 5 gallon bucket and epoxy in a hose fitting near the bottom. Attach a garden hose and attach a clear section of vinyl hose with couplings to the end of the garden hose. Depending where you set your bucket of water, it will give you that water line. A little food coloring in the water is also handy as well as a plug for the end of the vinyl hose (so you can lay the end down). (John Totman, #2698)

An addendum to my earlier hint on using an air bag and hairdryers to post cure the canard (Issue #10): It is possible to de-rate hairdryers by reducing the voltage (run them off a variac or variable transformer). The best dryers for this purpose can be run at high fan rate and low power. In this manner, it is very easy to control the bag temperature and not have to alter the safety wiring of the dryer.

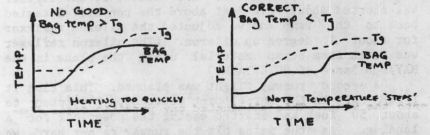

I had a 2" air bubble on my main wing top section outboard that passed shear web inspection but really should have required repair by sanding, glass layup, thermal properties of SAFE-T-POXY, I "repaired" the bubble as follows: 1) Drill micro injection hole and vent hole. 2) Inject SOME micro in one side of bubble (do not fill totally). 3) Heat local area (as small as possible) with hair dryer until noticeably soft. Compress bubble to spread micro and get rid of air pocket. Hold compression until piece has cooled. My .050" high bubble is now filled and flush with surrounding area. Note that if you reheat above the glass transition point (Tg=softening point) without allowing time for further curing, the piece will probably have residual stress (memory). Therefore, if you bring a piece up to post cure temps too quickly, a bubble repaired like this would probably reform. You could avoid this by "stress relieving" at an intermediate temperature, allowing substantial curing at the higher intermediate temperature. This increases the Tg and decreases chances of "creep" from getting too close to the initial softening temperature too quickly. (see graphs)

I suspect that this repair method can be used on any localized high spot on the main wing, elevators, ailerons, vertical stabilizer, etc. I would be hesitant on using it on the canard due to possible problems post curing later. It would save a tremendous amount of filling since any small high spot would require filling for several inches around it. Plus, the high spot usually incurs some damage from sanding. The man I talked to at Applied Plastics was Jack Barswell (213) 322-8050. I had called to talk to him about solvent resistance of epoxies, which led to a discussion on the softening point (Tg). The Tg is controlled by the degree of cross-linking of the polymer and is increased by holding a piece at an elevated temperature long enough for the additional cross-linking reactions to occur. The Tg is usually about 40 degrees above the curing temperatures. (Note the chemical resistance also increases dramatically with Tg, so it may be worthwhile to post cure things like gas tanks.) The net effect is you should be able to soften a piece, correct a defect and re-cure at a slightly higher temperature without affecting the integrity of the piece or having to worry about the defect re-occurring in the hot sun some day.

Applied Plastics is totally unconcerned with post curing at 200+ degrees F, and in fact; say it will withstand 300 degree F. Therefore, there is no danger from overheating EXCEPT if you heat the piece up too fast, you pass the softening point and your work piece is susceptible to warping. Also, in our case, temps greater than 200 degrees should be avoided because of possible Styrofoam damage. Applied Plastics says that holding at a temperature for about 2 hours should be sufficient to increase the softening point about 30 degrees F above the cure temperature. Therefore, you should eliminate any chance of warping by heating the piece up 30 degrees every 2 hours to the final post cure temperature. Conversely, if you have a warp and want to straighten it, heat up quickly to about 50 degrees F. above the max temperature the piece has seen, apply corrective pressure and let cure.

Other information I found out: The strength of a 65-70% (by weight) fiber layup is about DOUBLE that of a 50% (by weight) fiber layup. You must apply pressure to get the fiber content above 40-50%. (No wonder vacuum bagged parts are superior!)

SAFE-T-POXY 'B' contains a styrene monomer as a viscosity improver. It is suggested that good ventilation be used due to these styrene vapors. I have taken to using a carbon mask ventilator.

SAFE-T-POXY shelf life is significantly greater than the 1-year advertised, provided it doesn't see temperature extremes. However, you do lose some styrene via diffusion through the plastic storage bottles. It has the same effect as changing the ratio slightly. (Bob Falkiner, #2015)

A few suggestions when glassing the wing and canard. 1) Measure the part to be glassed and cut fabric before starting. Leave fabric a few inches longer than part and label the cloth. 2) Mark outline of each spar cap on wing or canard with marker pen before starting. Mark center of spar cap position. 3) Cut spar caps and mark center of spar cap. Roll each end of spar cap toward the center (two rolls per cap). Remember, spar caps are cut to EXACT SIZE. When placing spar caps on wing or canard, one person stands at the center holding both rolls. Place about 6" of spar cap on wing at centerline. The other person takes one roll and unwinds it, placing the end on wing marks. Rest of spar cap falls into place. Repeat process with other roll. Spar cap can now be straightened and frazzles removed. About 2 minutes for each spar cap. (William Adams, #528)

I also cut the spar caps in advance, but found it easier to drape the UNI skins from the original roll onto the wing. This eliminated any possible error from mismeasurement and allowed the cloth to be applied directly without excessive handling. This method does require an assistant with a strong back to hold the heavy cloth roll, but works quite satisfactorily.

Also, with respect to laying the individual spar caps, a technique to straighten the individual fibers. After the caps have been layed out as described by Mr. Adams above and appropriately wetted, have one person apply firm pressure to the spar cap centerline. Another assistant goes to the end of the cap, lays their hand onto the edge and gently pulls the end outboard. Keep just enough downward pressure with the hand to avoid slipping. Also avoid pulling cap sections off the centerline. Repeat the process for each spar cap on the left and right sides. (Robert Herd, #478)

After attending the seminar in Oshkosh, I became aware of the need of as much information as possible from every Quickie builder. After cracking two canards, shortening two props and smashing two runway lights, it is kind of presumptuous to give anybody good advice, but then maybe somebody could avoid the same mistakes and save some grief. Here is my contribution: 1) ALWAYS check for water in the tank. I didn't, and the engine quit one minute before takeoff. If that would have happened after takeoff, I would have ended up in the raspberries. 2) Do a first-class ground check. I discovered a broken engine mount bolt. 3) Trim back to neutral before landing. I did not which resulted in a broken canard and prop. Now, I'm sure there are countless other chances of doing some foolish things, but I will let somebody else discover them. Please tell all of us about it.

Also, I would install the drain plug on the bottom of the gas tank as close as possible to the left. Who wants to get down on his knees in long, wet grass? (Erich Mehlhase, #1010-Can.)

John Beck brought to our attention that the J.C. Whitney Catalog (P.O. Box 8410,Chicago, Il 60680) had several items, which might be of interest to homebuilders. After a bit of browsing, the following items seemed interesting:

</P><BR><P>For those having difficulty with the epoxy dispenser: Besides occasional cleaning and keeping a heat source (light bulb) to maintain a good viscosity, I found that when the dark side hangs up, I use a long, small pointed screwdriver and force the valve (inside the dark resin reservoir) up and down to loosen it up. (Philip Kelly, #2409)</P><BR><P>I have found an excellent method of epoxy cleanup. Instead of using MEK or acetone, which are nasty, smelly chemicals, I use a mild cleaning fluid called 1,1,1-Trichloroethane. I get it from IBM or it can be obtained from chemical or industrial cleaning supply houses. It should run about $8-$10 per gallon. The 1,1,1 is not flammable at all, but it can produce dangerous fumes if it comes in contact with open flame or hot surfaces, so don't clean a hot engine with it or throw the used stuff in the fireplace. This fluid doesn't produce rashes or headaches and you can hardly smell it compared with MEK or acetone. After a layup, I'll clean my brushes, tools and me with the 1,1,1-Trichloroethane, then Epocleanse before soap and water. I've gotten much cleaner brushes and tools since I've been using this combination.</P><P>There was a recent Breezy fatality in Illinois, which occurred because the aileron cables were hooked up backwards. This is not the first time that this has happened, yet people keep on doing it! We have an advantage in our construction projects to build fail-safes into our control rigging. If you are making your Quickie or Q2 trailerable, make your rudder cable quick disconnects staggered lengths so that it would be impossible to hook them up incorrectly. You could also have a male/female connection for one cable, and a female/male connection for the other. Paint your torque tubes one color for left controls and a contrasting color for the right. Don't let your survivors shake their heads over your wreckage and comment on how untimely your death was.</P><P>It would be a good idea to publish the mailing address and subscription fees for Rutan's CANARD PUSHER. There are a lot of Quickie and Q2 builders that don't know that this newsletter is available. Burt Rutan is the genius behind our method of design and construction and publishes some very important facts relating to composite construction that QAC doesn't come close to providing. In case you don't have it, the address is: Canard Pusher, Rutan Aircraft Factory, Building 13, Mojave Airport, Mojave, CA 93501. Subscriptions are $6.75 for USA and Canada. (Sam Hoskins, #2614)</P> <br /><hr /><p class=) You can order a PDF or printed copy of QuickTalk #11 by using the

You can order a PDF or printed copy of QuickTalk #11 by using the