QuickTalk 8 - QUICKIE HINTS

- Details

- Category: Q-Talk Articles

- Published: Monday, 28 February 1983 06:11

- Written by Jim Masal

- Hits: 2916

/This is the first section of a two-part report on modifications and alternatives to the Onan engine. Our members should keep in mind that several of the systems listed are still being evaluated and are provided for information purposes only. Naturally, QBA strongly recommends a thorough testing program before making any major power plant changes from the original plans. -Ed./

By Dean & Bob Walker, Ft. Collins, CO:

We would like to provide an interim report of our Onan engine development activities for the Quickie. After flying N793Q for about 20 hours last summer, we removed the engine as discussed later. We will attempt to document the development activities to date and our plans for the future. As it now stands, it looks like the engine has been a limiting factor in the success of the Quickie. Many of the builders we have talked to or read about have mentioned either lack of power or vibration as a problem. In lieu of changing to a completely new engine, we would hope our findings may help other builders "tune" their Quickie into the fine aircraft it has the potential of becoming.

EXHAUST SYSTEM - Initial effort was with the exhaust system. We were interested in a crossover style system with the idea of improving engine power through exhaust "tuning". We were also interested in reducing exhaust sound levels and removing the "putt-putt" sound of individual stacks. Two approaches were tested: 1. Acoustical tuning with long, equal-length pipes. We started with long pipes (longer than practical) and gradually reduced the length as tests progressed. 2. Inertial tuning was tested by installing various collector designs on the exhaust end of the individual equal-length pipes.

To check engine performance, we measured maximum static RPM with an electric stroboscope tachometer (accuracy within 2 RPM). We established a baseline performance for our engine using QAC standard exhaust stacks (3150 RPM with the 22.5 HP mod) and then checked RPM with various modifications, holding everything else constant.

We did not find any performance improvement with our exhaust tests (this confirmed some testing reported by QAC). However, the crossover collector style exhaust did produce a more pleasing type sound and possibly a slight reduction in noise level. Our engine flew briefly in another builder's Quickie and seemed to work fine.

CARBURETION - After tackling the exhaust, we began to look at carburetion. The basic premise was that several other engines we looked at with a displacement similar to the Onan (48 cu. in.) were using carburetors with larger throat area; indicating the Onan was possibly under-carbureted (especially the 22.5 HP version). In addition, we wanted to change the carburetor location to eliminate the clearance bump on the upper cowl (less drag, better visibility). We tried three different configurations:

1. Dual Tillotson (HL306B) - This is a diaphragm-type carburetor with butterfly throttle. The flat profile allowed mounting a carburetor adjacent to each intake port and clearance with the upper cowl. Results were: Increased static RPM +100 compared to the standard QAC set; hard to start; poor idle; ticklish to balance and lack of consistency.

2. Dual Walbro (LME series, Tecumseh #631564) - Float-type carb with butterfly throttle. Results were similar to the Tillotson.

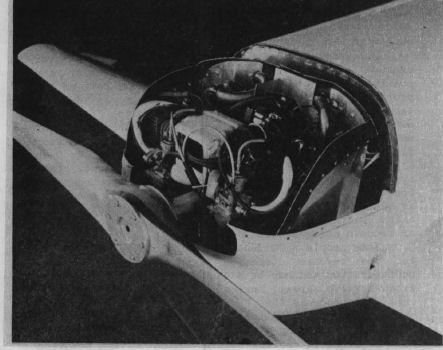

3. Dual Mikuni (VM 22-241) - This is a float-type carburetor with slide throttle. The size and shape of these carbs required mounting in front of the engine and below the intake ports (see photo). A common air intake box was mounted above the propeller shaft and each carburetor was connected to the intake port with a short tube. Results were: Increased static RPM +100; very easy to start; smooth idle; good acceleration. After considerable test running, we decided this configuration would fly.

ENGINE GROUND TESTS - We installed the engine with the cross-over exhaust system and dual Mikuni carburetors and found a fairly high level of vibration with the engine operating at full power (3250 RPM) and approximately 2000 RPM. This vibration had not been so noticeable on our test bench. We accomplished the following to bring the vibration down to a level we judged acceptable for flying:

a) We found the prop originally furnished with the kit to be out of balance and changed to a new 27 x 44 prop purchased from QAC.

b) The engine mount spacers were increased in length per recommendation by QAC and new rubber bushings were installed (the original bushings had taken a compression set).

c) We checked cylinder compression and found the cylinders to be 90 RH/75 LH. (The engine was "spun over" for the tests with a 1/2" drill motor bolted to the prop hub.) The exhaust valve on the low side was not seating properly, so we had the valves ground (courtesy of a local EAA member who is in the valve grinding business). This fixed the compression problem.

Each one of the actions taken seemed to help reduce vibration and collectively the reduction was quite noticeable. At this point the engine had approximately 15 hours of running time.

FLIGHT TIME - We flew the Quickie approximately 20 hours from June through mid-September 1982. From the very first flight, vibration was a big problem. What seemed acceptable on the ground was amplified in the air. We checked prop balance, checked alternator flywheel balance and changed the engine mount spacers/bushings with no problem or improvements. We were developing adequate power to climb and fly under the following conditions: 5000' ASL runway, 547 lbs. gross, 70-90 degree F., and approximately 200 FPM climb.

The engine started easily and operated with hesitation. We were very pleased with the engine throttle response in the air. The last few hours we flew, we noticed a gradual reduction in maximum static RPM (-50 RPM), an intake manifold cracked (due to vibration), and our overall vibration was not getting better. We decided to remove and disassemble the engine, primarily because we suspected the crankshaft to be dynamically out of balance. (We had checked everything externally, and the mounting can only isolate so much vibration.)

ENGINE TEARDOWN AND INSPECTION - We basically covered two discrepancies during engine teardown (dynamic crankshaft balance and head gasket leakage).

We took the crankshaft, piston and rod assemblies, prop hub and alternator flywheel to "Denver West Electronic Balancing". These people have been in the business about 40 years and were recommended to us by another EAA member. An initial balance check showed approximately 1 lb. of weight would need to be ADDED to the crankshaft counterweights to achieve dynamic balance. Since there is not enough room inside the crankcase to add this much weight, we looked at two alternatives: buy a new crankshaft or install the balance weight externally.

We first bought a new crankshaft from our Onan distributor, only to find out that the new crankshaft was just as "out of balance". The crankshaft, alternator flywheel and prop hub were balanced as an assembly with external weight attached to the alternator flywheel (5-1/2 oz.) and prop hub (3/4 oz.). It was interesting to note most of the weight was required on the rear half of the crankshaft.

Additional notes: 1) The Denver West people used a dummy weight attached to each crank journal to simulate the reciprocating mass effect of the piston and rod assemblies on the balance of the crankshaft. The pistons and rods were weighed and compared to each other for this purpose. 2) Another Colorado builder had his shaft balanced by Denver West and was found not as badly out of balance as ours. They used internal weight welded to his counterweights to achieve balance. The builder has indicated a definite improvement in vibration levels. 3) Gene Sheehan of QAC told us they have access to balancing services should a builder suspect this as a problem (contact QAC for more information).

We found evidence of leakage around the cylinder head gasket directly above each exhaust valve. The gasket was not "blown", simply leaking. This would explain the loss in static RPM during the last few flying hours.

MODIFICATIONS IN PROGRESS (No flight tests) - We have reassembled the engine and are currently working on three areas of improvement:

1. Single Carburetor - Have installed one larger Mikuni carburetor (Model VM26) with a "Y" manifold. The carb is mounted below the LH cylinder. Initial test have shown a 175 RPM increase over stock QAC. The single system is easier to adjust, save weight and makes possible a connection to ram air intake on lower cowl with air filter and carburetor heat.

2. Exhaust - Have designed a new crossover exhaust system to improve cylinder heat transfer and possibly reduce sound level. We believe part of the problem with cylinder head gasket leakage is due to lack of radiator area and heat transfer from the exhaust port, which causes a hot spot. Therefore, our new exhaust system uses a threaded adapter and radiator fin in an attempt to improve heat transfer. The Onan engine has threaded exhaust ports to facilitate this type of exhaust connection. Exhaust is routed away from the cylinder head area and through cooling baffles as quickly as possible to improve cooling. The exhaust exits out the bottom of the cowl with the possibility of reduced noise levels in the cockpit.

Some people have mentioned that cooling airflow is in the reverse direction compared to original configuration and may be a cause of poor cooling in the exhaust valve area. However, Gene Sheehan pointed out that Onan produces the "Vaccu-Flow" version of this engine for ducted cooling installations with the same direction of cooling airflow as the Quickie.

3. Improved cooling baffle design - By removing the carburetor from the upper center portion of the engine, we are now redesigning the rear baffle to extend forward on the upper crankcase and divert more airflow across the cylinder heads.

CONCLUSIONS - We are optimistic that the modifications discussed will result in the Onan giving satisfactory performance in our Quickie. Our bench tests are very encouraging and flight tests this spring will confirm. We believe that some of the engine performance variations being reported by builders are due to Onan normal production variations. This would certainly seem to be the case with our vibration problem, and we would encourage QAC (or the individual builder) to implement an engine vibration test (and balancing as required) as part of their quality control.

From Fred Stubbs, Ontario, Canada

Stubbs Aero Products (Hangar #4, Brantford Airport, P.O. Box 1264, Brantford, Ont. N3T 5T3, CANADA - (519) 756-2731) has very recently announced a new engine conversion package for the Quickie. The conversion package features a four-cylinder, two-cycle, radial engine manufactured by Konig Motorenbau of Berlin, Germany. The engine uses a rotary "X" design with alternate firing sequence for smooth operation. Each cylinder is fired by independent magnetos (four in all) for reliability and safety. A Bing carburetor in conjunction with a rotary intake valve supplies carburetion without hesitation or flat spots form idle to full power.

Full power at 28 HP is achieved from 570 c.c. displacement at 4100 RPM, thus allowing a direct drive system for the propeller. The engine design makes use of a large thrust bearing, forge hardened connecting rods with big split ends and needle bearing in both ends.

The Konig radial is lighter than the original Onan engine (45 lbs. versus 78 lbs). The lighter engine allows several beneficial changes: 1) The engine has been moved forward 10-1/2 inches, leaving plenty of room for installation and servicing. 2) The large 18 amp-hr battery is located on the front side of the firewall. 3) Addition of an exhaust silencer and electric starter without disturbing the CG. 4) The extended nose improves the overall appearance. The radial conversion package is actually 9 pounds lighter than the standard Onan.

Performance as tested on our heavy 306 lb. Quickie is impressive. Rate of climb has increased from 400 feet/min to 650 feet/min. Takeoff roll is 450 feet. Cruise speed 125 MPH, 135 MPH top speed. The conversion has done nothing to alter the already stable flying characteristics. Stall speeds and control responses remain the same. Overall, the aircraft is smooth, responsive and quiet.

Stubbs Aero is offering a COMPLETE conversion package, which can be retrofitted in approximately 25 man-hours. To an initial builder, a savings of 40-50 hours over the Onan installation time may be expected. The "SUPER-Q" conversion package contains: Konig four cylinder radial engine with conversion modifications, carburetor with throttle cable, exhaust manifolds with chrome silencer, electric starter, ignition harness and master switch (pre-wired), dash mounted primer, engine shock mounts, welded engine mount, premolded cowlings and prop spinner, predrilled propeller, prop spacer, front mounting plate, carb heat exchange box, hose clamps, tachometer (induction lead type), baffling materials, wire, electrical terminals and miscellaneous hardware.

Prices for the SUPER-Q Conversion Kit are: $3,495 Can., $2,895 U.S. (variable with exchange rate). As indicated, the package is very complete and of top quality. Above all, it gives the Quickie pilot a level of takeoff and climb performance well within the safety envelope.

You can order a PDF or printed copy of QuickTalk #8 by using the Q-talk Back Issue Order Page.