Q-talk 69 - LETTERS

- Details

- Category: Q-Talk Articles

- Published: Thursday, 30 April 1998 07:11

- Written by Tom Moore

- Hits: 3100

FIRST FLIGHT

Hi All,

My Q200, N200QK, had its first flight yesterday (Sunday, May 31st) morning at Livermore, CA (LVK). I had Gordy Jones in his LongEZ flying chase, with Barry Weber as observer. We flew a 40-minute flight following the recommended first flight profile. The flight went off flawlessly. Held the speed down to about 130 kts, and went to 5500 ft. Slight left wing heaviness easily handled by my spring roll trim. Practiced turns, pitch response, yaw response, slow flight (down to 70 kts), and found the power needed to descend 500 fpm at 85 kts. We then went back to LVK and did a practice approach low pass with the LongEZ on my wing, and then back around to land. Good landing, no problems. Highest oil temp was 190, highest cyl head temp about 350. Ambient temp was about 75 degrees.

This has been a 16-year project and it all seems worthwhile now. This airplane is about the sweetest flying airplane I have ever flown - beautiful control balance, responsive, etc. I also have to add that based upon a lot of high speed taxiing and one landing it is one of the easiest taildraggers to land that I have flown and I have flown a bunch of them over the years. If anybody has any doubts about finishing their bird, keep going. It's great!

I'm going to try to make Oshkosh, if I can get the hours flown off in time.

Bob Farnam, Livermore, CA

Ed. Note: Way to go Bob!! Hope to see you in OSH.

BETTER LATE THAN NEVER

COPPERSTATE DASH AIR RACE

Dave Carlson took fourth place in the Copperstate fly-in last year. Dave was entered in the Copperstate Dash race in the 75 hp or less category. Dave averaged a 146 mph from a standing start on this 350-mile course. Not bad for less than 75 hp.

Dave had won this event in 1995, so it's good to see Dave out there showing off the capabilities of his Q2.

Dear Fellow QBAers,

We are making some substantial progress toward completion of my prototype LS(1) canard for the Quickie-1 using Graphlite carbon fiber rod as the new spar material. Most of the design headaches are now but a sour memory, although a few hurdles still remain to be overcome. Many of you may remember my frustrations with the slow-going progress early on, but the design was completed this past November and I had intended to begin work immediately and continue through the winter. El Nino put a stop to that with atypically low temperatures and rain, rain, RAIN! Progress was further delayed by a number of other factors until this past month, when the whole project was moved back into my hangar, and our Chapter Technical Counselor graciously began to lend a valuable helping hand. All the hotwiring of the foam cores for both the leading and trailing edges, as well as the elevators is now successfully completed and was performed during several hours on two weekends. By bringing the whole project back to Livermore, we made more progress in those two weeks than in the preceding six months! The cores look great and have so far not been subject to warping. The elevator slot cores are glassed and have been separated from the trailing edge cores as per the new instructions. My table is ready to go and I plan to begin assembly and jigging this weekend.

A number of you have requested to borrow the templates and have wanted more specifics. We can't release the templates until a successful static load test is performed, followed by flight-testing; this is for liability reasons. But I can detail some highlights relative to the design itself that are interesting and unique. Remember that this is a new venture using a new material, which has never before been extensively used in homebuilt applications. Graphlite has been studied as the primary spar material for the Akrotech G-200 and G-202, and Boeing and Rockwell have been Neptco's primary customers for the time that this material was being manufactured. Graphlite has now been discontinued by Neptco, and currently there is still no substitute. I have bought out every bit the company had left, which is enough material to ensure completion of four projects. I am offering it for sale at my cost, which incidentally is way below what QAC was charging for the older tubular carbon fiber spars.

The Graphlite material for this application is about 1/16th inch in diameter and can bend around corners (in fact, it is delivered wound on a large wooden spool. The Graphlite weighs nothing at all, but the spool weighs a ton!) This flexibility is one reason why the rods were attractive for this particular application. They are designed to run continuously from one end of the canard, through the anhedral bend at BL 10 and then to the opposite tip. Consequently, the rods do not join in the center like on the older tubular spar design. It is important to remember that the rods must be continuous for them to do their job (rods must never be butted end to end if there isn't one of sufficient length. The strength won't be transferred through the entire rod.) The rods are placed so as to taper out to the canard tips and they occupy a trapezoidal area when viewed from the top. Thus, the entire rod pack on both the upper and lower surfaces of the canard tapers from the full width of rods laminated side by side in the trough (about 3 inches wide, in one single layer) at the BL 10 position, tapering out to very few extending all the way out to the tips. Incidentally, almost a half-kilometer of rod material is required for one project; amazing!

One of the most interesting aspects of design deals with washout or twist. The templates were designed with no washout in them. Here's why, in the words of the designer: "The templates all have two lines on them - a 'chord line' and what I have named a 'level line' (on the root template these are one and the same). Ideally you would use the level line to level each template before performing your hot wire cut. This would create cores with the proper twist 'built in'. But things get more complicated if you do not have one very large foam block (standard max width for the foam is 14 inches) to cut out both your leading and trailing edge cores together as one piece. Since this is so, you will have to join two blocks together. At this point you have two options. You can temporarily join the two blocks together at some location other than the forward shear web, mount your templates with the proper relative twist, and cut your cores. This will leave you with cores with the proper twist but you will still have to join the two cores together once again where you had the joint and then make another cut at the location of the forward shear web. The second option is to join the blocks temporarily at the location of the forward shear web to begin with. This option eliminates the need to rejoin and re-cut the cores but has the drawback of requiring you to cut the cores without any twist. You cannot cut twist into the cores because you have already defined the shear web as being the joint between the two blocks. And to keep the forward shear web on each template in line with the junction between these two blocks you have to place the templates on the core blanks with no twist in them. This is actually a relatively simple concept to visualize but considerably more difficult to explain. Regardless of which option you choose to cut your cores, the original jigging templates were designed to keep the proper twist in the cores. So as long as you can get the cores to sit properly in the jig after cutting, everything should turn out dandy." We elected to go with the recommendation of the designer, making only the one cut in the foam and defining that as the shear web.

Consequently, yesterday, my hangar partner (Bob Farnam, who incidentally conducted a flawless first flight of his Q-200 last weekend!) and I, using his AutoCAD system, designed a set of vertical jigs to be used in glassing the shear web vertically, respecting twist, anhedral and sweep. No need now to rotate the whole table 90 degrees, or build a framework on top of the table to hold the cores in the proper relative position to each other while the shear web is being glassed. What we thought was going to be a major headache has now turned into a very simple procedure. We'll provide these vertical jigging templates along with the hot-wiring templates once the design is released.

That's about all for now. I fully intend to have a completed canard by the Ottawa fly-in and will bring pictures! Hope to have some time also to talk briefly about any other little hurdles that crop up in the meantime. This is getting exciting and I'm finally having fun!

Alan Thayer, Castro Valley, CA

(510) 582-7274 or This email address is being protected from spambots. You need JavaScript enabled to view it.

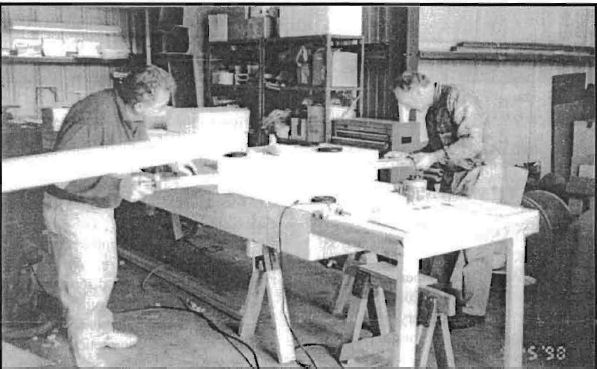

Gordon Jones (L) and Alan Thayer hot wiring foam cores for a new LS-(1) 0417

The following article was taken off of the Internet from the EZ Squadron web site. I contacted the author, Cary Thomas, about the story and he allowed the reprint.

Thanksgiving week I discovered that I had roasted the rings on number 2 cylinder to the piston. So with some friends help I disassembled the engine, fixed the problem and reassembled it. While the cowls were off, I decided to change the oil and filter.

I have the spin-on adapter for the O-200, which used the Champion CH48108 oil filter. So with everything back together I hand-propped the engine to life. NO OIL PRESSURE! Shut 'er down. OK, you DID remember to remove that old T-shirt from the #2 hole in the crank case, right? Maybe I didn't give it enough time for the oil pressure to come up. Fire 'er up again, wait 45 seconds. NO OIL PRESSURE! I have TWO gauges, one analog and one digital. Can't be the gauges. OK, maybe the oil pressure line is plugged. Remove it, fire 'er up again. No oil comes out of the line at the engine -- NO OIL PRESSURE! Finally, it hits me - perhaps the OIL FILTER is not letting oil pass through. I remove the brand new oil filter and it is completely dry inside. BINGO! Donnya at Carlsbad Aircraft Supply is gracious enough to replace the filter for free and return the defective filter to the supplier. Put on the replacement filter and everything is JUST FINE. My friends said they have NEVER heard of such a thing!

So, next time you change your oil filter, if you get NO OIL PRESSURE, you might want to look to the filter! (And, yes, the strangest things ALWAYS happen to ME.)

Cary Thomas

Here's some information I picked up on the gas springs for my canopy at Austin Hardware.

1790 Radisson Rd. N.E., Minneapolis, MN 55449-0007

Ph. 612-780-4333

The product number is AHP 6280. You will probably need to order the ball stud that the strut connects to also. The cost in July of 1996 was $28.30 for 2 springs.

Some of the guys have asked about the Hi Temp room cure epoxy that I made my engine cooling boxes out of. Their address is:

ADTECH CORP.

P. O. Box F, Charlotte, MI 48813

Ph. 1-800-255-9934 or 517-543-7510

The part number is EL335 R/H - 1-qt unit $25.03

Bruce Crain, Enid, OK

QBAers,

Considering the fact that many of us are seeing the big clock in the sky add up the years it is reasonable to assume that, sooner or later, our bodies start playing nasty tricks on us. One of several results of this is that our friendly employees in the FAA seem most interested in our welfare and wonder if we are becoming a threat to the General Public. Being the concerned folks that they are they like to examine us in great detail. Not withstanding the fact that other folks within the DOT don't seem to lose too much sleep over ninety year old drivers approaching each other on the highways at a closer rate of over a hundred miles per hour within ten or twenty feet of each other. Therefore when a "mature" pilot has a tiny little old stroke (TIA) or perhaps a heart bypass procedure done, or both, our friends get down right interested in our welfare. Their great concern sets into motion a scenario designed to cause many to surrender and purchase a shiny new golf cart. But, there are some who just don't appreciate their oversight obligations and forge ahead telling anyone who will listen that, of course I'm not a danger to society after all I have been flying for over half a century and haven't bent a plane yet. Got shot down once in Viet Nam but that wasn't my fault. Some stranger wearing black pajamas and shower clogs didn't understand that I was really over there helping him and got off a lucky shot. For those of you who don't understand the big picture and decide to fight the system you might take notes regarding my not unusual experience.

In May of 1996 after squeezing my Tri-Q onto the Rochester International Airport's seven thousand foot runway I noticed that my right hand and leg were just excess weight, wouldn't do what I expected of them. With great skill I managed to taxi to the hangar with only my right leg available for breaking action and when I called ground control I realized that I couldn't talk either. Made lots of neat sounds with the help of my noise reduction Telex AR-4000, which I had just acquired, and with lots of dumb questions from the tower cab, which I ignored, managed to arrive at my bird infested T-hangar. Getting to the Mayo Clinic seemed like a good idea so, of course, drove myself there and into the ER. More strange sounds and grunts didn't help much in responding to the "who is your insurance carrier" type questions. The only ID I had with me was my military retirement card, which failed to impress anyone. And all the time I thought it was a hell of an important piece of paper. In any event, after two days they sent me home with the stern admonition that I take a baby aspirin daily for as many years as I can remember to do so.

Being a law and order person, like all good military people are, I wrote the FAA advising them of the event stating that I had grounded myself, mistake #1. They were so quick to respond that I felt they had been waiting for my message and suggested that I "volunteer to surrender my medical" ala Bob Hoover. Being the law and order person I am, the medical went in by return mail. In their letter they were kind enough to tell me that I was not required to give up my ticket, but if I didn't they would have no choice but to hand it over to the enforcement folks for actions deemed appropriate.

Weeks later, after seeing my Tri-Q go down the aerial road into the hands of another person totally unqualified to treat 4832-L in the manner in which it had become accustomed to, I wrote to determine what steps were required to attain the status of a pilot once again. I was informed that a year must transpire before I even think of bothering them. Before that year had passed, while on a skiing vacation in Arizona, I experienced the intense pain known to so many people as Angina. My clean living was rewarded once again and managed to get into the Mayo Clinic in Scottsdale. The Mayo system is one gigantic organization and in moments my records were transmitted west and after a few days of delightful tests they decided that a heart bypass would be a nice way to conclude my Arizona vacation. After a sixty-eight thousand dollar visit to their Scottsdale hospital I flew home. Pleased to be alive and impressed with the fact that my children and brothers all flew out to be with me to remind me what a grand chap I was. Great healing medicine.

Back in Rochester I went into the Mayo Clinic rehab program, which is excellent, and my daughters gave me a membership in a wonderful new athletic club recently established in town. I decided to lick this and, my friends, this is key. We must have a positive mental attitude towards these little challenges life sends our way. I worked like a dog five days a week at the club and made good progress. After six months I started the re-certification process. My AME, who has gazed at my body for twenty years, sent in the usual application which quickly generated a response from Oklahoma City listing all the tests required before they would even look at my papers. I won't bore you with the details but I doubt if there is any test Mayo has available that I didn't get. In fact they added up to about three thousand dollars. Many EKGs, MRI, Cat Scan, treadmill stress tests, lots of blood tests, a detailed neurological exam to check out the previous TIA and others I have since forgotten.

Up to this point I had no argument with the system. The first flag rose when a month after forwarding the thick file I called to make sure they had it and was informed that just that very day it had been logged into the system. Been in the "mail room" for a month. About once a month I would call a very polite lady working there whom, after checking her computer, would say it was either in "review" or waiting for a screening. Five months later my AME and I received a letter asking for two more small little elements of information. Another treadmill stress test and another neurological evaluation. I did 120% of their target for men my age on the treadmill and the neurologist reported to them that there was no evidence whatsoever of ever having had a TIA. The feds invited us to fax this data to them to accelerate the process. This sounded great to me, now I knew that Oklahoma City was just waiting to hear from me. Any by the way, they required that only board certified specialists at Mayo administer and report on the tests. I must say that those guys were great and put wonderful positive spins on their letters. After another month I called Loretta at OKC and she confirmed the fact that the fax had arrived and that the papers were in review. Every three weeks I called with the same results so I went to my AME and he agreed to call the following Monday. On Saturday the long awaited, beautiful piece of paper arrived. It had taken eight and a half months and many dollars for this day to appear. The very next day I hired the toughest CFI available for a BFR, which I am please to report I passed. Now I am tearing up the sky in a rented C-150. Take off at 55, climb at 70, cruise at 90, approach at eighty and hunt for 65 for over the fence. Heck of a deal.

All of the above, I think, establishes a couple of points. Be prepared to experience a long and frustrating delay with the system. If you need medical programs to return to flying, do them with vigor. I am convinced that asking your AME to call for you will do far more than attempting to do it ourselves. We all must support EAA and AOPA in trying to get this mess cleaned up and I feel one way is to use the AMEs to a much greater extent.

My medical was dated eight months ago but they gave me eight months before renewal time. My AME, after reasonable minor tests, has said when that date arrives, he will send in the data but will issue me a ticket and let the FAA decide what they will do. After the next issue, they have said my cards will be good for a twelve month period with only the usual application.

Morale: Hang Tough, we can beat them.

Walt Halloran, Rochester, MN

You can order a PDF or printed copy of Q-talk #69 by using the Q-talk Back Issue Order Page.