Q1 Plans Chapter 3 Page 3-6

- Details

- Category: Quickie Plans

- Published: Friday, 14 November 2008 00:00

- Written by Dan Yager

- Hits: 9394

working periods, keep some resin & hardener in the warmest place of your house for use on the next layup.

Save your mixing cups, as they can be used as a quality check of your epoxy. After a day or two take a sharp knife point or scribe and scratch the surface of epoxy in the cured cup. If the epoxy cured properly the scribe will make a white scratch mark. If the epoxy hasn’t cured the scribe will make a dull ridge, indicating a soft surface. If this occurs the epoxy is not cured either due to inadequate time or temperature, or bad mixing or bad epoxy.

Microspheres

Microspheres are a very light filler or thickening material used in a mixture with epoxy. Micro, as the mixture is called, is used to fill voids and low areas, to glue foam blocks together, and as a bond between foams and glass skins. Several different types of microspheres and microballoons are available commercially. The quartz-type supplied by QAC distributors is lighter and cheaper than most common types. Microballoons must be kept dry. If moisture is present it will make them lumpy, bake thea at 250°F then sift with a floor sifter to remove lumps. Keep the microballoon container covered.

Micro is used in three consistancies: a "slurry" which is a one-to-one by volume mix of epoxy and micro- spheres, “wet micro” which is about two-to-four parts microspheres by volume to one part epoxy, and "dry micro” which is a mix of epoxy and enough microspheres to obtain a paste which will not sag or run (about five parts—to—one by volume). In all three, microspheres are added to completely mixed epoxy.

You do not have to accurately mix the microspheres; just dump them in until the desired consistancy is obtained. Micro slurry is used to paint over foams before glass cloth is applied over them. Slurry is almost the same viscosity as the pure epoxy and is runny enough to apply with, a brush. However, the easiest way to apply slurry is to pour it onto the surface and spread it out evenly using a squeegee. When skinning urethane foam use a full thick coat of slurry. Inadequate slurry on urethane can result in a poor skin bond. Wet micro is used to join foam blocks and, while it is much thicker than slurry, it is still thin enough to sag and run (like thick honey). Dry micro is used to fill low spots and voids and is mixed so that it is a dry paste that won’t sag at all. In all three micro types, you don’t measure, just add microspheres until the desired consistancy is obtained. Use micro only as specifically shown - never use micro between glass layers.

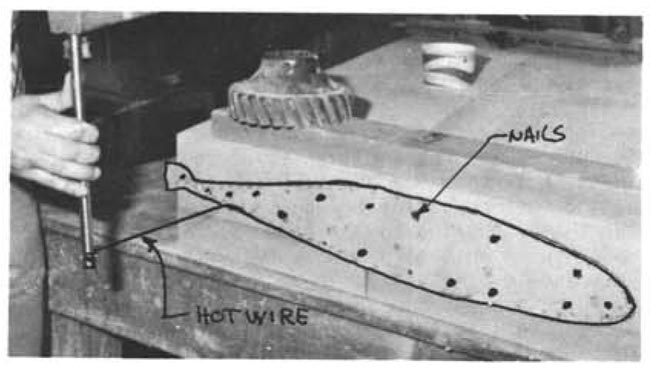

JOINING FOAM BLOCKS WITH MICROPHERES/EPOXY

Always use the following method to join foam blocks. This is extremely important. Always use RAES.

- Check that the foam blocks fit closely together. If there are voids over 1/16 inch, sand to fit or fill the void with a sliver of foam.

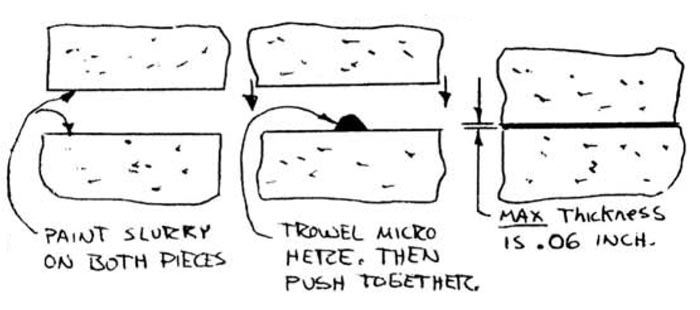

- Paint a light coat of micro slurry on both surfaces. If joining foam to fiberglass paint pure mixed epoxy (no microspheres) on the fiberglass surface and micro slurry on the foam surface.

- Refer to the sketch and trowel wet or dry micro in the center of the joint. Thus when joined the micro is pushed outward expelling (rather than trapping) air. If the fit is excellent use wet micro. If it is open enough and vertical such that epoxy may run out, use dry micro.

- Push the two pieces together, wiggling each to move the micro toward the surfaces. Be sure the micro is no thicker than 0.1 inch at any place, to avoid exotherm. Wipe off any excess. Do not be concerned if the micro does not completely reach the surface. That void can be filled immediately before skinning the part.

Flox

Flox is a mixture of cotton fiber (flocked cotton) and epoxy. The mixture is used in structural joints and in areas where a very hard durable buildup is required. Flox is mixed much the ssme as dry micro, but only about two parts flock to one part epoxy is required. Mix in just enough flock to make the mixture stand up. if “wet flox” is called out, mix it so it will sag or run.

When using fiox to bond a metal part be sure to sani the metal dull with 220- grit sandpaper and paint pure mixed epoxy (no flox) on the metal part.

BONDO

Bondo

Throughout these plans the term “Bondo” is used as a general term for automotive polyester body filler. Bondo is used for holding jig blocks in place and other temporary fastening jobs. We use it because it hardens in a very short time and can be chipped or sanded off without damaging the fiberglass. Bondo is usually a dull gray color until a colored hardener is mixed with it. The color of the mixture is used to judge how fast it will set. The more hardener you add, the brighter the color of the mixture gets, and the faster it hardens. This simple guide works up to a point where so much hardener is added that the mixture never hardens. Follow the general directions on the Bondo can for fast setting Bondo. Mixing is done on a scrap piece of cardboard or plywood (or almost anything) using a hard squeegee or putty knife. A blob of Bondo is scooped out of the can and dropped on the mixing board. A small amount of hardener is squeezed out onto the blob and then you mix to an even color. You will mix the blob for about one minute. You will then have two to three minutes to apply it before it hardens.

Be sure to clean the board and putty knife off before the Bondo is completely hard. MEK will clean Bondo off your putty knife and squeegee if it isn’t completely hardened.