Q1 Plans Chapter 3 Page 3-7

- Details

- Category: Quickie Plans

- Published: Thursday, 13 November 2008 00:00

- Written by Dan Yager

- Hits: 10753

Foam

Three different types of rigid, closed-cell foam are used (and several densities). A low density (2 lb/ft3), blue, large—cell styrofoam is used as the foam core of the wings, rudder, and canard. The blue foam is exceptional for smooth hot wire cutting of airfoil shapes. The large cell type used provides better protection from delamination than the more commonly used insulation-grade styrofoams.

Low density 2 lb/ft3 green (or light tan) urethane foam is used extensively in the fuselage and fuel tanks. Urethane foam is fantastically easy to carve and contour and is completely fuel proof. The urethane used is U-Thane 210 or equivalent.

PVC foam in medium and low densities is used in fuselage bulkheads and other areas where higher compressive strength is required. The light red PVC is 61b/ft3 and the orange is 3lb/ft3. Do not substitute foams for those supplied by the Quickie distributor . For example, the Quickie blue styrofoam has great glass surface peel strength than the standard blue styrofoam sold by some distributors. Also, we considered using the "fire resistant" BROWN urethane instead of the green 2-lb urethane, but found its physical properties, fatigue life, and fuel compatibility to be much lower than the urethane supplied to Quickie builders. Do not confuse styrofoam with white expanded polystyrene. Expanded polystyrene is a molded, white, low density, soft foam, which has the appearance of many spheres pressed together. This is the type used in the average picnic cooler. It disappears immediately in the presence of most solvents, including fuel, and its compression strength and modulus is too low.

All three types of foams, PVC, urethane snd polystyrenes are manufactured in a wide variety of flexibilities, densities and cell sizes. Getting the wrong material for your airplane can result in more work and/or degraded structural integrity.

Sun damages foam, keep it covered.

HOT WIRE CUTTING

The airfoil-shaped surfaces of your VariEze are formed by hot wire cutting the blue styrofoam of 2lb/ft3 density. The hot wire process gives airfoils that are true to contour, tapered, properly twisted, and swept with a minimum of effort and the simplest of tools. The details for making your hot wire saw were shown on page 3-2.

The hot wire saw is a piece of stainless steel safety wire, stretched tight between two pieces of tubing. The wire gets hot when an electricial current passes through it and this thin, hot wire burns through the foam. By making smooth steady passes, the hot wire gives a smooth, even surface. The foam offers little resistance to the hot wire’s passage. To get a smooth accurate cut, a template is required. Templates are made from thin plywood, sheet metal, masonite or formica. A variable voltage control is used to supply the electrical current that heats the wire.

The blue foam used in your flying surfaces was selected for a combination of reasons and its hot wire cutting ability was one of them. Other types of foams are readily hot wire cut, but some (white explanded polystyrene) have poor physical properties and others (urethane) give off poisonous gases when hot wire cut. Use only the recomeanded materials!

Hot wire templates can be made from 1/16 to 1/4-inch plywood, formica, or masonite .032 to .064 sheet metal. It is importsnt to have smooth edges on the templates. A rough edge may cause the wire to hang up and burn into the foam excessively. Templates are required on both ends of the foam being cut. The size, shape, and orientation of the two templates is varied to taper, and twist the foam core as required. The planform (span end sweep) is set by squaring up the foam block before the templates are used. In general, the trailing edge of the wing is the reference.

Full-size template drawings are provided in the plans. To make your templates, just glue the template drawings to a piece of plywood or sheet metal and trim to the contours shown. There are a number of markings on each template which aid in the alignment and cutting of the foam core.

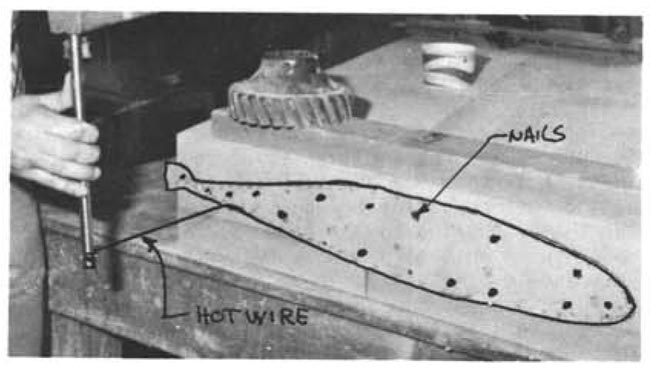

Each template has a waterline (W.L.) marked on it which is used to align the twist of the foam core. Each template’s waterline is leveled using a carpenters bubble level. This assures that the relative twist at each template is correct. The template is then nailed to the foam block to obtain the correct plan form.

Each rib template has numbered marks running from the trailing edge around the leading edge and back to the trailing edge. These are called “talking numbers.” When the foam cores are cut into their airfoil shape, the talking numbers are used to assure that each end of the hot wire is coordinated to obtain the correct, tapered airfoil. The person calling the numbers should be at the largest template. A typical cut would sound like this: “Resting on the tab 1/4” from the foam, moving forward, entering foam now - one, half, two, half, . . . , 34, half, 35, half, 36, coming out of the foam and pausing on the tab, wire’s out.” As the cut is made, the person on the small rib follows the numbers, passing over them as he hears them called out. Pause marks are indicated in places where it is necessary to pause for a couple of seconds and let the hot wire’s center lag catch up with the ends.

Praparing a foam block for an airfoil cut is begun by trimming the rectangular foam block to the basic dimensions for the correct planform. These “trim” cuts are made using two straightedged trim templates. The templates are held against the foam by nails through the template into the foam. Enough nails should be used to hold the template firm so that it won’t move when the hot wire is held against it.