QuickTalk 1 - QUESTIONS & ANSWERS

- Details

- Category: Q-Talk Articles

- Published: Sunday, 28 February 1982 06:11

- Written by Jim Masal

- Hits: 2672

Q: Is anyone out there looking into some soundproofing ideas for making a quieter Quickie/Q2? (Darrel Aleson, #2045)

Q: Does anyone have a good, light filtering system to get the alternator noise out of an Escort 110 installed in a Quickie? (Dick Menning, #179)

Q: Concerning making the Q2 trailerable, Deltec Aircraft has not responded to my inquiries. What changes have to be made to the Q2 to mount it on the trailer? (Ronald Cross, #2397)

Q. We are nearing the stage to join the upper and lower fuselage halves, but find they must be drawn together to make them match for final taping. Can you suggest an uncomplicated way to achieve? Also, is there any easy way to match fore and aft to make the Q2 trailerable? (J. Wesley Ray, #2249)

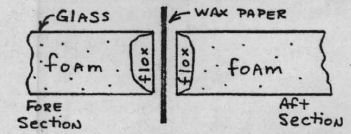

A. The method my partner and I used gave us very satisfactory results. A cross-section of the airplane at the fore/aft cut line is a circular pattern. The smaller the diameter of that circle, the easier it will be to have the fore and aft sections mate tightly. Therefore, the fuselage cut line should be close to the tail as possible. (Since the fuselage tapers toward the tail, the cross section becomes smaller.) Begin by making a stiff plywood sanding board, which is larger than the cross-section of the airplane. Don't be surprised at it taking 9 or more sheets of sandpaper to cover it. Using two individuals, pull the sanding board back and forth against the forward section as you would a double-handle lumberjack saw. A third person is helpful to apply pressure to the center of the board. Only sand enough of the forward section to achieve a smooth uniform circle. Now, flip the board and begin grinding down the aft section. As you continue sanding, the diameter of the "aft" circle will become smaller and approach that of the "forward" circle. When you get close, sandwich the sanding board tightly between the two surfaces and continue to sand. This will "match-sand" the two halves at the same angle.

The above should get you a satisfactory result. However, we went just one more step. We dug out the foam around those carefully sanded edges and over-filled them with wet flox. We put wax paper between the fore and aft sections and carefully mated the surfaces. After curing, the halves separate easily and any extra flox that oozed out the sides is sanded down. (Courtesy Richard Adams, #2068)

You can order a PDF or printed copy of QuickTalk #1 by using the Q-talk Back Issue Order Page.