Q-talk 93 - Prop "Clocking" or Indexing

- Details

- Category: Q-Talk Articles

- Published: Wednesday, 23 December 2009 16:24

- Written by David Gall

- Hits: 3082

David Gall Oviedo, FL

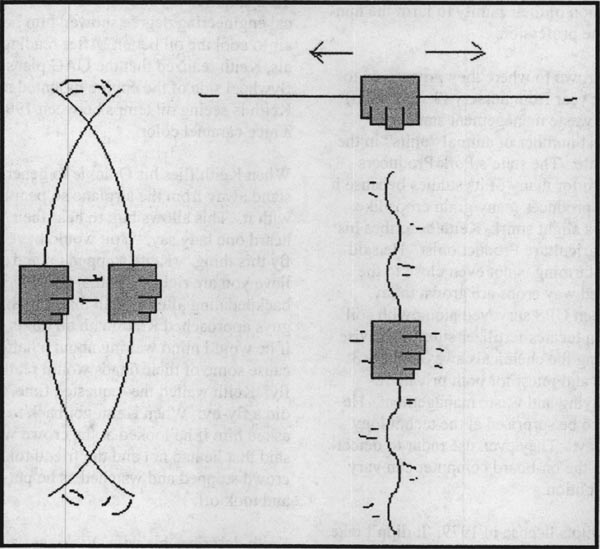

Four-cylinder engines produce a yawing vibration with a primary frequency of twice engine speed. For a two-bladed prop, this means that the blades can be positioned to align with the horizontal (translational) motion of the end of the engine each time the internal engine forces are forcing this vibration, or the blades can be at some angle, even perpendicular, to the horizontal motion when the forces are at their peak.

An example: If you grasp a yard-stick (meter-stick) in its middle and hold it vertically while shaking your hand horizontally, you will induce a strong bending load on the stick. With practice, you can find its natural frequency and get a significant amount of visible bending. However, if you hold it horizontally and perform the same motion, you will not induce any bending in the stick at all. The stick will behave for all intents and purposes as though you had a block of wood in your hand of the same mass as the stick, but compact.

While holding the stick vertically and performing the above experiment, if you suddenly stop your hand, you will find that the vibrating stick tries to force your hand to continue vibrating as the stick dissipates its vibrational energy back into your hand. Your hand becomes the absorber of energy stored in the stick. This same process was occurring while you were driving the stick to vibrate, only you didn't notice it except, perhaps, as a cue to you to adjust your vibration rate to try to match the resonant frequency of the stick. That's how "practice" allows you to find the natural frequency of the stick.

Back to the absorber function, when your hand is driving the stick and the stick is reflecting some of its stored vibrational energy back into your hand, you'll notice that your whole upper body is shaking with the exercise, but your feet aren't. Somewhere between the hand and feet, the energy is dissipated in that soft, fleshy mass :-). This should give a clue as to what condition we want our engine mount rubbers to be in: soft and pliable, in correct proportion, of course, to the loads and frequencies they need to absorb. Old, dried out engine mount rubbers, then, are the first thing to check/change when tracking down a vibration problem.

Returning to prop clocking (you thought I forgot, didn't you!), you've no doubt already figured out that the prop should be bolted on to be in line with the cylinders when the pistons are at top/bottom dead center. (On four-cylinder engines, all cylinders get there at the same time.) Quoting from the "Sky Ranch Engineering Manual" by John Schwaner: "Historically, propellers are indexed 60 degrees ahead of horizontal so the propeller is in a convenient position for hand propping. However, if you do not intend to hand-prop the engine, this index configuration [horizontal at T/BDC] will minimize transmitted vibration levels."

Since the Ivo prop probably has a lower level of damping than a wood prop, it makes even more sense to index the prop correctly to minimize vibration.

As a side note, this has even greater applicability to two cylinder opposed engines like the Onan and half-VW engines, since these engines do not have the internal countering of forces that is provided by the other two cylinders in a four-banger. Six-cylinder engines have the least concern with prop clocking since they are almost completely primary-and secondary-balanced internally.

I have been told by a manufacturer of air boat engines that the small two-cylinder V-twins will break props if the prop is mounted to the PTO shaft, but that by placing the prop on the opposite side of the flywheel from where the cylinders are, they can be used direct-drive with no problems.

This air boat manufacturer makes a prop hub just for the purpose of mounting to the flywheel of the Kohler 25 hp Command Series engine, and they sell them to AIRBOAT builders. They operate under the name Great Plains Aircraft Supply..:-)

http://www.greatplainsas.com/airengine.html

You can order a printed copy of Q-talk #93 by using the Q-talk Back Issue Order Page.